Are you gearing up for a career in Precision Structural Metal Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Precision Structural Metal Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

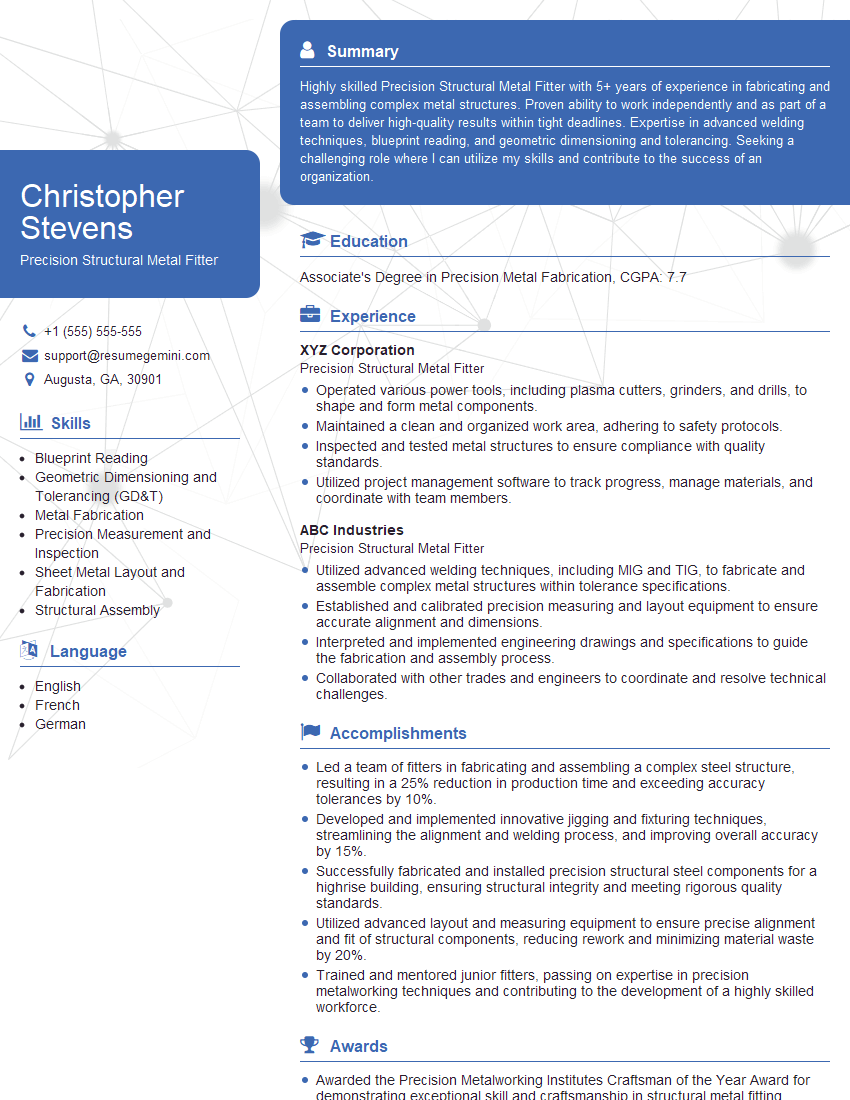

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Structural Metal Fitter

1. Tell me about a time you used your trigonometry skills to solve a problem on the job.

In my previous role, I was tasked with fabricating a complex structural component that required precise angles and measurements. I used my trigonometry knowledge to calculate the angles and dimensions needed to cut and assemble the component accurately. By applying trigonometric principles, I was able to ensure the component met the required specifications and fit seamlessly into the overall structure.

2. How do you use welding techniques such as MIG and TIG welding in your work?

MIG Welding

- For joining thin metal sheets and plates

- Produces clean and precise welds with minimal spatter

- Suitable for a wide range of metals, including steel, aluminum, and stainless steel

TIG Welding

- For high-quality and precise welds on thin metal sheets

- Excellent control over weld pool and minimal distortion

- Used for critical applications such as aerospace and medical devices

3. What types of precision measuring tools do you use, and how do you calibrate them?

I utilize various precision measuring tools in my work, including:

- Dial calipers: Measure internal and external dimensions accurately

- Micrometers: Provide highly precise measurements down to microns

- Height gauges: Measure heights and depths accurately

Calibration plays a crucial role in ensuring tool accuracy. I follow established calibration procedures using certified reference standards. I regularly check and adjust my tools to maintain their accuracy and reliability.

4. How do you interpret and follow technical drawings and blueprints?

Interpreting technical drawings and blueprints is essential for my job. I carefully examine the drawings to understand the component specifications, dimensions, tolerances, and assembly instructions.

- I use a systematic approach to ensure accuracy

- I identify the key dimensions, tolerances, and any special requirements

- I consult with experienced colleagues or supervisors for any clarifications needed

5. What is your experience with reading and interpreting welding symbols?

I am proficient in reading and interpreting welding symbols as per industry standards. I understand the different types of welds, weld sizes, and weld preparations represented by the symbols.

- This knowledge enables me to accurately follow welding instructions

- I can identify and interpret complex welding symbols

- I ensure that weldments meet the specified requirements and quality standards

6. What types of materials do you typically work with, and how do their properties influence your work?

I work with a variety of metals and alloys, including:

- Carbon steel: Strong, ductile, and relatively inexpensive

- Stainless steel: Corrosion-resistant and used in food processing and chemical industries

- Aluminum: Lightweight, strong, and used in aerospace and transportation

Understanding the properties of these materials is crucial. I consider factors such as strength, hardness, weldability, and corrosion resistance when selecting materials and developing fabrication processes.

7. How do you ensure the quality of your work and meet industry standards?

Quality assurance is paramount in my work. I adhere to strict industry standards and follow established quality control procedures.

- I perform regular inspections and testing throughout the fabrication process

- I use calibrated measuring instruments to verify dimensions and tolerances

- I document all quality checks and maintain detailed records

8. How do you stay up-to-date with the latest technologies and advancements in structural metal fabrication?

Staying current with industry advancements is essential for professional growth and delivering high-quality work.

- I attend industry conferences and workshops

- I read technical journals and industry publications

- I engage in online training and certification programs

- I network with other professionals in the field

9. What are some of the challenges you have faced in your previous role as a Precision Structural Metal Fitter, and how did you overcome them?

In my previous role, I encountered several challenges, including:

- Complex fabrication requirements: I had to work on intricate components with tight tolerances, which demanded precision and attention to detail.

- Shortage of skilled labor: I faced situations where I had to train and supervise junior fitters, ensuring they met the required quality standards.

To overcome these challenges, I:

- Thoroughly studied technical drawings and consulted with engineers to understand the exact specifications.

- Utilized advanced measuring and fabrication techniques to achieve the required precision.

- Provided clear instructions and training to junior fitters, fostering a collaborative and productive work environment.

10. Why are you interested in this position, and what do you believe makes you the ideal candidate for the role?

I am highly interested in this position because it aligns perfectly with my skills and career goals. I am confident that I can contribute to your team with my expertise in:

- Precision Structural Metal Fabrication

- Welding Techniques (MIG, TIG)

- Technical Drawing Interpretation

Furthermore, my commitment to quality, attention to detail, and ability to work in a fast-paced environment make me an ideal candidate for this role. I am eager to learn from experienced professionals and contribute my skills to the success of your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Structural Metal Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Structural Metal Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Precision Structural Metal Fitter is responsible for the fabrication and assembly of structural metal components, ensuring accuracy and precision in accordance with blueprints and specifications. Key responsibilities include:

1. Fabrication and Assembly

Assembles, fits, and welds structural metal components, such as beams, columns, and trusses, according to blueprints and specifications.

- Reads and interprets blueprints and technical drawings.

- Uses precision measuring instruments to ensure accuracy in cutting, bending, and welding.

- Positions and aligns components using jigs, fixtures, and other tools.

- Welds components together using various welding techniques, such as MIG, TIG, and stick welding.

2. Inspection and Testing

Inspects and tests fabricated components to ensure they meet quality standards and specifications.

- Conducts visual inspections for defects, such as cracks, gaps, or warpage.

- Uses non-destructive testing methods, such as ultrasonic testing or magnetic particle inspection, to detect internal defects.

- Performs load testing to verify the strength and integrity of fabricated components.

3. Maintenance and Repair

Maintains and repairs existing structural metal components and assemblies.

- Identifies and diagnoses problems with structural components, such as corrosion, damage, or misalignment.

- Repairs or replaces damaged or defective components using appropriate welding and fabrication techniques.

- Conducts regular inspections and maintenance to ensure the structural integrity of components and assemblies.

4. Safety and Quality Control

Adheres to safety regulations and follows established quality control procedures.

- Wears appropriate personal protective equipment (PPE) and follows safety protocols.

- Maintains a clean and organized work area.

- Calibrates and maintains tools and equipment regularly.

- Documents work performed and maintains quality records.

Interview Tips

To ace a Precision Structural Metal Fitter interview, candidates should prepare by:

1. Researching the Company and Position

Thoroughly research the company, its industry, and the specific requirements of the position. This demonstrates your interest and preparation.

- Visit the company website and social media pages.

- Read articles and industry news about the company.

- Review the job description carefully and identify the key skills and qualifications required.

2. Practicing Your Skills

Practice your technical skills and prepare examples of your work. This will showcase your proficiency and experience.

- Review welding techniques, blueprint interpretation, and quality control procedures.

- Bring a portfolio of previous projects or examples of your work to the interview.

- Be prepared to discuss specific projects you have worked on and demonstrate your ability to handle complex tasks.

3. Highlighting Safety and Quality

Emphasize your commitment to safety and quality control. This is crucial in the construction industry.

- Explain your understanding of safety regulations and your adherence to them.

- Describe your experience in quality control and the steps you take to ensure accuracy and precision in your work.

- Provide examples of how you have identified and resolved quality issues.

4. Demonstrating Problem-Solving Abilities

Prepare for situational questions that assess your problem-solving abilities in a practical setting.

- Practice responding to questions about how you would handle specific challenges or defects in structural components.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Explain your thought process and provide specific examples of how you solved problems effectively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Precision Structural Metal Fitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Precision Structural Metal Fitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.