Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Broaching Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

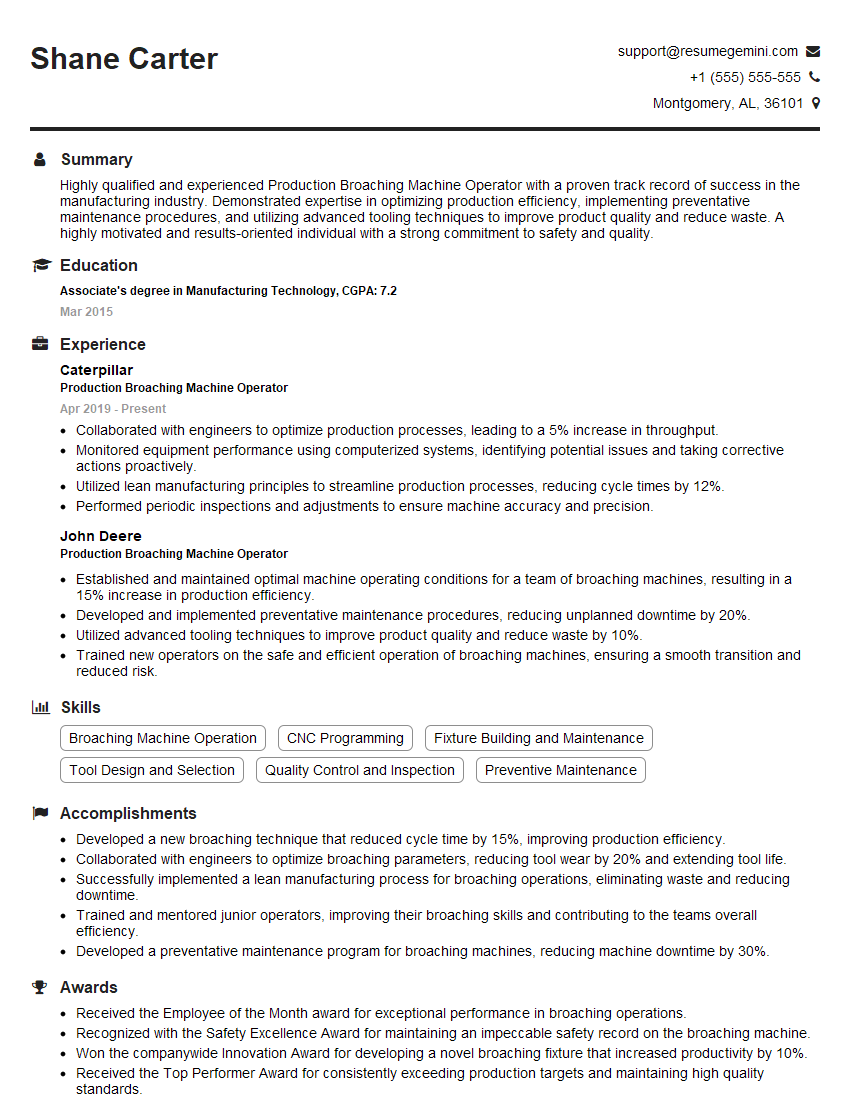

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Broaching Machine Operator

1. Can you describe the process of setting up and operating a production broaching machine?

To set up and operate a production broaching machine, I follow these steps:

- Secure the workpiece in the fixture.

- Select the appropriate broach tool.

- Set the machine parameters, including speed, feed, and stroke length.

- Start the machine and monitor its operation.

- Inspect the finished workpiece to ensure it meets specifications.

2. What are the different types of broach tools and their applications?

Internal broaching

- Round broaches: Used to create round holes.

- Spline broaches: Used to create splines in shafts.

- Keyway broaches: Used to create keyways in shafts.

Surface broaching

- Flat broaches: Used to create flat surfaces.

- Profile broaches: Used to create complex shapes.

3. What factors affect the surface finish of a broached part?

- Condition of the broach tool

- Material of the workpiece

- Speed and feed rate

- Lubrication

- Coolant

4. How do you maintain and troubleshoot a production broaching machine?

Daily maintenance includes:

- Cleaning and lubricating the machine

- Inspecting the broach tools for wear and damage

- Checking the hydraulic fluid level

Troubleshooting:

- Machine not starting: Check power supply, hydraulic fluid level, and safety switches.

- Poor surface finish: Check broach tool condition, speed and feed rate, and lubrication.

- Excessive noise: Check for worn gears or bearings.

5. What is your experience with programming and operating CNC broaching machines?

I have experience programming and operating CNC broaching machines using various CAM software. I am proficient in creating and editing NC programs, setting up work offsets, and optimizing cycle times.

6. Can you explain the safety precautions that must be observed when operating a production broaching machine?

- Wear appropriate PPE, including safety glasses, gloves, and earplugs.

- Keep hands clear of the cutting area.

- Ensure the workpiece is securely fixtured.

- Never attempt to remove chips or debris from the machine while it is running.

- Follow all lockout/tagout procedures before performing maintenance or repairs.

7. What is your understanding of the different types of broaching defects and how to prevent them?

Common broaching defects:

- Chattering: Caused by vibration, improper fixturing, or dull broach tools.

- Tearing: Caused by excessive cutting forces, improper lubrication, or worn broach tools.

- Burnishing: Caused by insufficient cutting fluid or excessive cutting speed.

- Pull-out: Caused by insufficient clamping force or improper workholding.

Prevention:

- Use sharp broach tools and proper fixturing.

- Ensure adequate lubrication and cutting fluid.

- Optimize cutting parameters (speed and feed).

- Inspect broach tools regularly and replace them when necessary.

8. How do you stay up-to-date with the latest advancements in production broaching technology?

To stay up-to-date with the latest advancements in production broaching technology, I:

- Attend industry trade shows and conferences.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Consult with equipment manufacturers and industry experts.

9. Can you provide an example of a successful project you have worked on that involved broaching?

In my previous role, I was involved in a project to increase production efficiency of a keyway broaching operation. By optimizing cutting parameters, implementing a new fixturing system, and training operators on best practices, we were able to reduce cycle time by 20% and improve surface finish.

10. What are your career goals and how does this position align with them?

My career goal is to become a highly skilled and experienced production broaching machine operator. I believe this position aligns with my goals because it will allow me to develop my skills, contribute to a team, and make a valuable contribution to the manufacturing industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Broaching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Broaching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Broaching Machine Operators are responsible for operating and maintaining broaching machines, which are used to cut and shape metal parts. They must be able to set up and operate the machine, as well as inspect the finished parts to ensure that they meet specifications.

1. Setting Up and Operating the Machine

Production Broaching Machine Operators must be able to set up and operate the broaching machine according to the specifications for the job. This includes setting up the machine’s tooling, workholding fixtures, and cutting parameters.

- Set up and operate broaching machines according to specifications.

- Load and unload workpieces from the machine.

- Monitor the machine’s operation and make adjustments as needed.

- Troubleshoot and resolve machine problems.

2. Inspecting Finished Parts

Production Broaching Machine Operators must be able to inspect finished parts to ensure that they meet specifications. This includes checking the parts for dimensions, surface finish, and other quality characteristics.

- Inspect finished parts to ensure that they meet specifications.

- Use measuring tools and gauges to check dimensions and surface finish.

- Identify and correct any defects in the parts.

- Maintain records of inspection results.

3. Maintaining the Machine

Production Broaching Machine Operators must be able to maintain the broaching machine to ensure that it is operating properly. This includes cleaning and lubricating the machine, as well as replacing worn parts.

- Clean and lubricate the broaching machine.

- Replace worn parts.

- Perform preventive maintenance tasks.

- Keep records of maintenance activities.

4. Safety

Production Broaching Machine Operators must be able to follow safety procedures to avoid accidents. This includes wearing appropriate safety gear and following lockout/tagout procedures.

- Follow safety procedures.

- Wear appropriate safety gear.

- Follow lockout/tagout procedures.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few tips that can help you ace the interview for a Production Broaching Machine Operator position.

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website and social media pages.

- Read articles about the company and its products or services.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare a concise and engaging answer to the question “Tell me about yourself.”.

- Highlight your skills and experience that are relevant to the position.

- Be prepared to discuss your strengths and weaknesses.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Choose clothes that are comfortable and allow you to move freely.

- Avoid wearing clothing that is too revealing or too casual.

- Make sure your clothes are clean and pressed.

4. Be Confident and Enthusiastic

Confidence is key during an interview. Be confident in your abilities and your experience, and let the interviewer know that you are enthusiastic about the position.

- Maintain eye contact with the interviewer.

- Speak clearly and confidently.

- Be enthusiastic and positive about the position.

5. Follow Up After the Interview

After the interview, be sure to send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and to thank the interviewer for their time.

- Send a thank-you note within 24 hours of the interview.

- Thank the interviewer for their time.

- Reiterate your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Broaching Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.