Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Production Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

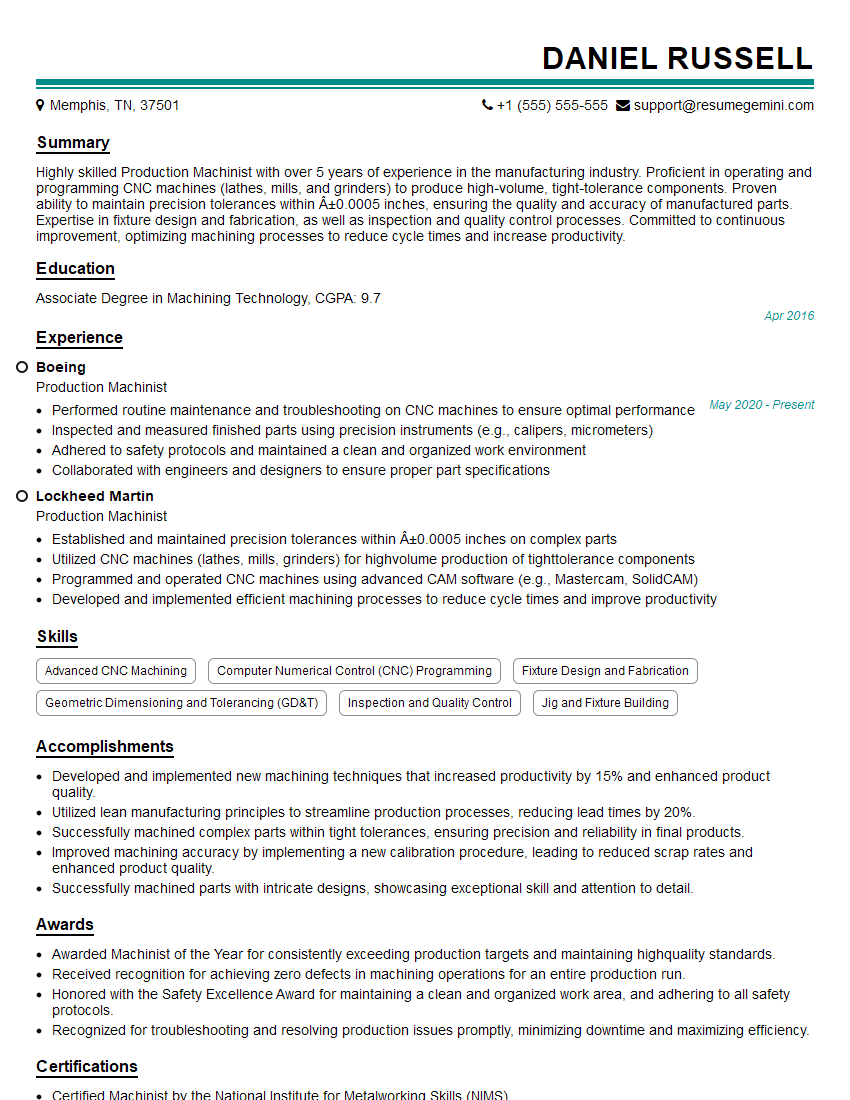

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Machinist

1. Describe the process of setting up and operating a CNC lathe.

To set up and operate a CNC lathe, I follow a systematic process:

- Machine Preparation: I mount the workpiece securely on the chuck and align it with the spindle.

- Tool Selection: I select appropriate cutting tools based on the material and operation requirements.

- Program Loading: I load the CNC program into the machine controller.

- Setup Verification: I verify the program and perform a dry run to ensure there are no collisions.

- Operational Monitoring: I monitor the machining process and adjust parameters like spindle speed and feed rate as needed.

- Tool Maintenance: I maintain tools by cleaning, sharpening, and replacing them to ensure optimal performance.

2. How do you handle deviations from specified tolerances in machined parts?

Identify the Deviation

- I measure the part and compare it to the specified tolerances.

- I identify the source of the deviation, whether it’s setup error, tool wear, or material variation.

Corrective Actions

- If it’s a setup issue, I adjust the machine settings or workpiece alignment.

- If it’s tool-related, I replace or adjust the tool to correct the deviation.

- If it’s material-related, I consult with the engineering team to adjust the process parameters or material specifications.

3. Explain the importance of coolant selection and its impact on machining operations.

Coolant selection plays a crucial role in machining operations:

- Temperature Control: Coolant helps dissipate heat generated during machining, preventing thermal damage to tools and parts.

- Lubrication: It reduces friction between the tool and workpiece, improving tool life and surface finish.

- Chip Removal: Coolant flushes away chips from the cutting zone, ensuring smooth operation and preventing tool clogging.

- Corrosion Protection: It protects the workpiece and machine from corrosion.

Choosing the right coolant depends on factors like material type, cutting speed, and the desired surface finish.

4. How do you optimize cutting parameters for different materials and machining operations?

To optimize cutting parameters, I consider the following factors:

- Material Strength and Hardness: Harder materials require slower speeds and lower feed rates.

- Tool Geometry: Different tool shapes and materials have different optimal cutting parameters.

- Operation Type: Roughing operations can tolerate higher feed rates than finishing operations.

- Machine Capabilities: I consider the spindle speed and power limitations of the machine.

- Desired Surface Finish: Smoother finishes require lower feed rates and higher spindle speeds.

I typically start with recommended values and adjust the parameters based on trial cuts and observations.

5. What techniques do you use to maintain the accuracy and precision of CNC machines over time?

To maintain accuracy and precision:

- Regular Calibration: I perform spindle and axis calibrations as per the manufacturer’s guidelines.

- Preventive Maintenance: I schedule regular checkups and lubricate moving parts to prevent wear and tear.

- Temperature Control: I monitor the temperature of the machine to prevent thermal drift and maintain dimensional stability.

- Tooling Maintenance: I ensure tools are sharp and properly set to minimize deflection and vibrations.

- Vibration Isolation: I use vibration dampeners and vibration-absorbing mounts to minimize external influences.

6. Describe your experience with troubleshooting common CNC machine problems.

I have encountered various CNC machine problems and resolved them through systematic troubleshooting:

- Electrical Faults: I check wiring, fuses, and relays to locate electrical issues and repair or replace faulty components.

- Software Errors: I diagnose and correct software errors by reviewing logs, checking for bugs, and updating software versions.

- Mechanical Problems: I inspect mechanical components such as bearings, belts, and gears for wear or damage, and replace or repair as needed.

- Process Issues: I analyze cutting parameters, tooling, and coolant conditions to identify process-related problems and optimize the machining process.

7. How do you ensure that machined parts meet quality standards and customer requirements?

To ensure quality and meet customer requirements:

- Inspection and Measurement: I conduct thorough inspections using measuring tools and equipment to verify dimensions, tolerances, and surface finishes.

- Quality Control: I adhere to established quality control processes, including documentation and record-keeping.

- Continuous Improvement: I analyze inspection results and identify areas for improvement in processes and procedures.

- Customer Feedback: I gather customer feedback to understand their expectations and make necessary adjustments to meet their requirements.

8. What are some best practices for safety when working with CNC machines?

Safety is paramount when working with CNC machines:

- Proper Training: I ensure I have received adequate training and certification on machine operation and safety procedures.

- Machine Guards: I always use safety guards, interlocks, and other protective devices to prevent accidents.

- Personal Protective Equipment: I wear appropriate PPE such as gloves, safety glasses, and earplugs.

- Clear Work Area: I maintain a clean and organized work area, free of tripping hazards and clutter.

- Emergency Stop Button: I familiarize myself with the location of the emergency stop button and know how to use it in case of an emergency.

9. Describe your experience with different types of CNC machines and controls.

I have experience with a wide range of CNC machines and controls:

- Lathes: CNC turning centers, Swiss-type lathes, multi-axis lathes

- Milling Machines: Vertical machining centers, horizontal machining centers, 5-axis milling machines

- CNC Controls: Fanuc, Siemens, Heidenhain, Mazak

- CAD/CAM Software: SolidWorks, Mastercam, CAMWorks

Each type of machine and control has its unique capabilities and programming requirements, and I am proficient in operating and programming them.

10. What are your career goals and how does this position align with them?

My career goals are to continue developing my skills in precision machining, become an expert in CNC programming and optimization, and contribute to the manufacturing sector.

This position aligns well with my goals:

- Technical Challenges: The complex and demanding nature of the role provides opportunities to expand my technical capabilities.

- Growth Potential: The company’s commitment to employee growth creates a platform for me to advance my career and take on leadership responsibilities.

- Industry Contribution: By producing high-quality and precise parts, I can contribute to the success of the company and the broader industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Machinists are responsible for operating and maintaining a variety of machines to produce precision parts for use in a wide range of industries.

1. Machine Operation

Machinists must be able to operate a variety of machines, including lathes, milling machines, grinders, and drills.

- Set up and operate machines according to specifications

- Monitor machines during operation and make adjustments as needed

2. Quality Control

Machinists must be able to inspect parts to ensure that they meet quality standards.

- Inspect parts for defects using a variety of tools and gauges

- Identify and correct any defects found

- Maintain quality records

3. Maintenance and Repair

Machinists must be able to perform basic maintenance and repairs on machines.

- Clean and lubricate machines

- Troubleshoot and repair minor problems

- Order and install replacement parts

4. Safety

Machinists must follow safety protocols to prevent accidents.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

- Report any unsafe conditions

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific role you are applying for. Learn about the company’s products or services, its size, and its reputation. Identify the key responsibilities of the position and make sure you can speak to how your skills and experience align with those requirements.

- Visit the company’s website and social media pages

- Read news articles and industry publications

- Network with people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver clear and concise responses during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Highlight your skills and experience that are most relevant to the position

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for the interview. Arrive on time and be prepared to shake hands with the interviewer and make eye contact. Throughout the interview, maintain a positive and confident demeanor.

- Wear clean, pressed clothes that fit well

- Choose conservative colors and avoid wearing too much jewelry or makeup

- Arrive 10-15 minutes early for the interview

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. Prepare a few questions in advance, such as “What are the biggest challenges facing the company right now?” or “What is the company culture like?”

- Avoid asking questions that are too personal or unrelated to the position

- Be prepared to answer questions about your questions

- Thank the interviewer for their time and reiterate your interest in the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Production Machinist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.