Are you gearing up for a career in Protector Plate Attacher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Protector Plate Attacher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

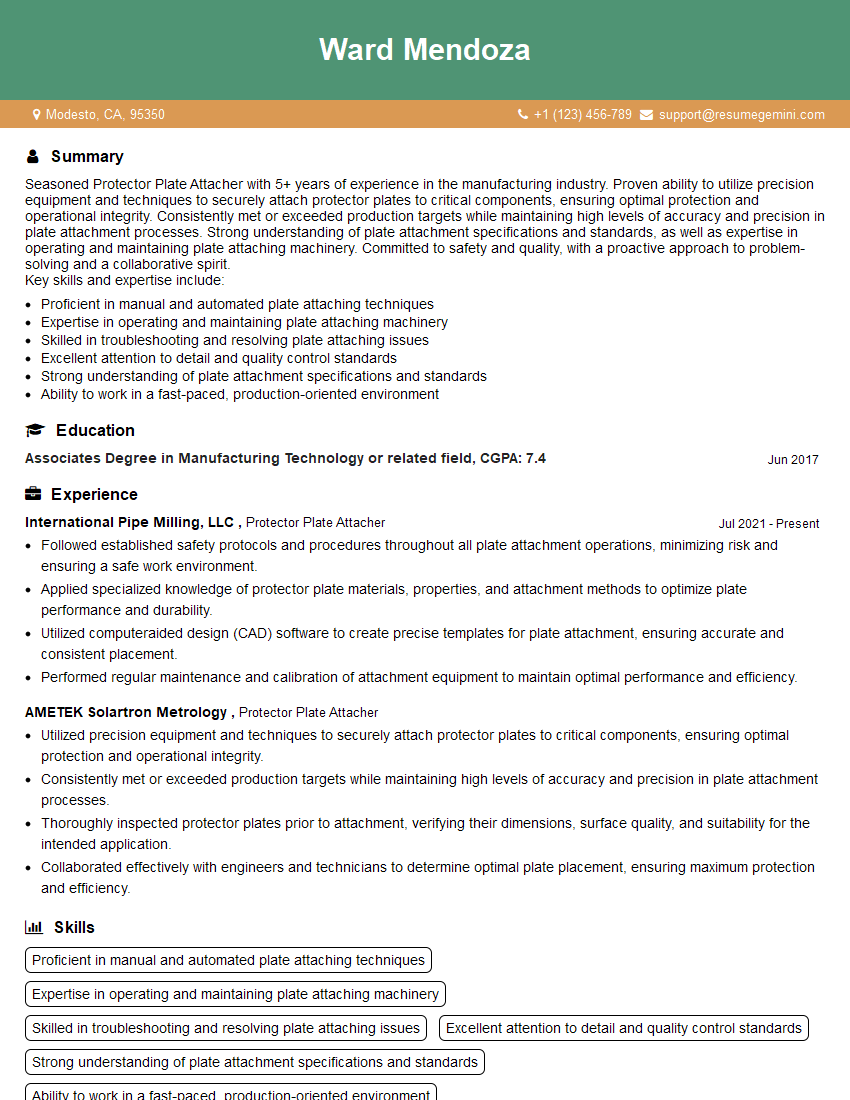

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Protector Plate Attacher

1. Describe the process of attaching a protector plate to a structure?

The process of attaching a protector plate to a structure involves several steps:

- Preparation: Clean and prepare the surface where the protector plate will be attached, ensuring it is free of debris and contaminants.

- Plate Placement: Position the protector plate accurately on the structure, following the specified blueprints or guidelines.

- Drilling: Drill holes through the protector plate and into the structure, using the appropriate drill bit size and ensuring correct alignment.

- Bolting: Insert bolts or screws into the drilled holes and tighten them securely, creating a firm connection between the protector plate and the structure.

- Inspection: Thoroughly inspect the attachment to ensure it meets specifications, including bolt torque, plate alignment, and overall stability.

2. What types of materials are commonly used for protector plates?

Metals:

- Steel: High strength and durability, used for heavy-duty applications.

- Stainless Steel: Corrosion-resistant and aesthetically pleasing, suitable for outdoor environments.

- Aluminum: Lightweight and durable, used in aerospace and automotive industries.

Polymers:

- Polyethylene: Impact-resistant and flexible, used for protective barriers.

- Polycarbonate: Transparent and resistant to UV rays, used for glazing applications.

3. What are the key factors to consider when selecting a protector plate?

- Purpose: Determine the specific function of the protector plate, whether it’s protection from impact, wear, or corrosion.

- Environment: Consider the environmental conditions, such as temperature, humidity, and exposure to chemicals.

- Load Requirements: Calculate the expected loads and stresses on the protector plate to ensure it can withstand the forces.

- Material Properties: Select a material that meets the required strength, durability, and corrosion resistance for the application.

- Cost and Availability: Balance the performance requirements with budget and material availability.

4. Describe the safety precautions that should be taken when working with protector plates?

- Wear Protective Gear: Use safety glasses, gloves, and appropriate clothing to protect against sparks, dust, and sharp edges.

- Secure the Work Area: Ensure the work area is clear and free of trip hazards or potential falling objects.

- Handle Plates Safely: Use appropriate lifting equipment and techniques to avoid injury from heavy plates.

- Use Sharp Tools: Maintain sharp drill bits and other tools to reduce force required and prevent accidents.

- Follow Instructions: Carefully follow the manufacturer’s instructions and blueprints to ensure proper installation and safety.

5. Explain the importance of regular inspection and maintenance of protector plates?

- Early Detection of Damage: Inspections can identify any signs of wear, corrosion, or cracks, allowing for timely repairs.

- Ensured Safety and Reliability: Regular maintenance ensures that protector plates are functioning as intended, reducing the risk of failures or accidents.

- Extended Lifespan: Proper maintenance can extend the lifespan of protector plates by addressing minor issues before they escalate into major problems.

- Compliance with Regulations: Inspections and maintenance meet regulatory requirements and demonstrate responsible management of safety equipment.

- Cost Savings: Preventative maintenance and repairs are typically more cost-effective than major repairs or replacements.

6. Describe a challenging project you worked on where protector plate attachment was critical?

I recently worked on a project involving the installation of protector plates on a high-rise building to protect against potential falling debris. The challenge lay in the intricate design of the structure and the need for seamless integration of the plates into the existing facade.

To overcome this, we meticulously planned the attachment points, ensuring minimal impact on the aesthetics of the building. We used specialized drilling equipment and high-strength fasteners to create secure and robust connections between the plates and the structure.

Regular inspections and maintenance were implemented to ensure the ongoing integrity and performance of the protector plates, contributing to the overall safety of the building and its occupants.

7. How do you stay up-to-date with the latest industry standards and best practices for protector plate attachment?

- Industry Publications: I subscribe to technical journals and magazines to stay informed about new materials, techniques, and regulations.

- Conferences and Seminars: I attend industry conferences and seminars to learn from experts and network with professionals.

- Online Resources: I utilize online platforms and databases to access technical articles, manufacturer specifications, and best practices.

- Collaboration with Colleagues: I regularly engage in discussions with colleagues and share knowledge to stay abreast of advancements in the field.

8. What are some common mistakes that can occur during the attachment of protector plates?

- Improper Surface Preparation: Neglecting to properly clean and prepare the surface can lead to weak bonds and premature failure.

- Incorrect Bolt Torque: Over- or under-tightening bolts can compromise the integrity of the connection and cause damage to the plate or structure.

- Insufficient Attachment Points: Failing to use an appropriate number of attachment points can result in the plate being inadequately secured.

- Use of Incompatible Materials: Mixing different materials, such as using dissimilar metals, can lead to galvanic corrosion and weaken the connection.

- Lack of Regular Inspection: Neglecting to conduct regular inspections and maintenance can allow damage or wear to go undetected, potentially leading to safety hazards.

9. How do you ensure the accuracy and precision of your work when attaching protector plates?

- Detailed Planning: I carefully review blueprints and specifications to ensure a clear understanding of the requirements.

- Precision Tools: I use calibrated tools, such as digital levels and torque wrenches, to achieve accurate measurements and connections.

- Quality Control Measures: I implement quality control measures, including visual inspections and testing, to verify the accuracy and integrity of my work.

- Continuous Improvement: I regularly evaluate my techniques and seek feedback to identify areas for improvement and maintain high standards.

10. What additional skills or certifications do you have that make you a suitable candidate for this role?

- Welding Certification: I am certified in various welding techniques, enabling me to fabricate and repair protector plates if necessary.

- NDT Inspection: I am trained in non-destructive testing methods, allowing me to assess the integrity of protector plates and ensure proper attachment.

- Safety Management: I have completed safety management courses and am familiar with industry best practices for hazard identification and risk mitigation.

- First Aid and CPR Training: I am certified in first aid and CPR, demonstrating my commitment to workplace safety and emergency preparedness.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Protector Plate Attacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Protector Plate Attacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Protectors Plate Attachers are responsible for attaching protector plate to the vehicle chassis. Their other duties include all the tasks related to Protector plate attaching process.

1. Attaching Protector Plates

Protectors Plate Attachers are responsible for securing protector plates to protect the chassis of the vehicle. This involves using specialized equipment such as welding or riveting machines.

2. Inspecting for Defects

It is crucial to check the protector plates for any defects or damage prior to attaching them to the vehicle chassis. Attachers inspect the plates to ensure they meet the required standards and are free from dents or cracks.

3. Equipment Maintenance

Attachers are required to inspect and maintain the attaching equipment. This involves ensuring the equipment is in proper working order, calibrated, and clean for optimal performance.

4. Documentation and Record Keeping

Detailed records of all attachments must be maintained by the Protector Plate Attachers. This includes documenting the type of plate used, the location of the attachment, and the date of the attachment.

Interview Tips

Interview preparation is key to making a great impression on potential employers. Here are some tips and tricks to help you ace your interview for a Protector Plate Attacher position.

1. Research the Company

Before the interview, take the time to research the company you are applying to. This will give you a better understanding of their business, values, and the specific role you are interviewing for.

2. Practice Your Answers

Prepare for common interview questions and practice your answers. You should be able to articulate your skills, experience, and why you are a good fit for the position.

3. Highlight Your Skills

In your interview, be sure to highlight your skills and experience that are relevant to the Protector Plate Attacher position. Emphasize your attention to detail, your ability to work independently, and your knowledge of the attaching process.

4. Prepare Questions

At the end of the interview, you will likely be given the opportunity to ask questions. This is a great chance to show your interest in the position and the company. Ask thoughtful questions that demonstrate your understanding of the job and the industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Protector Plate Attacher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.