Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Prototype Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

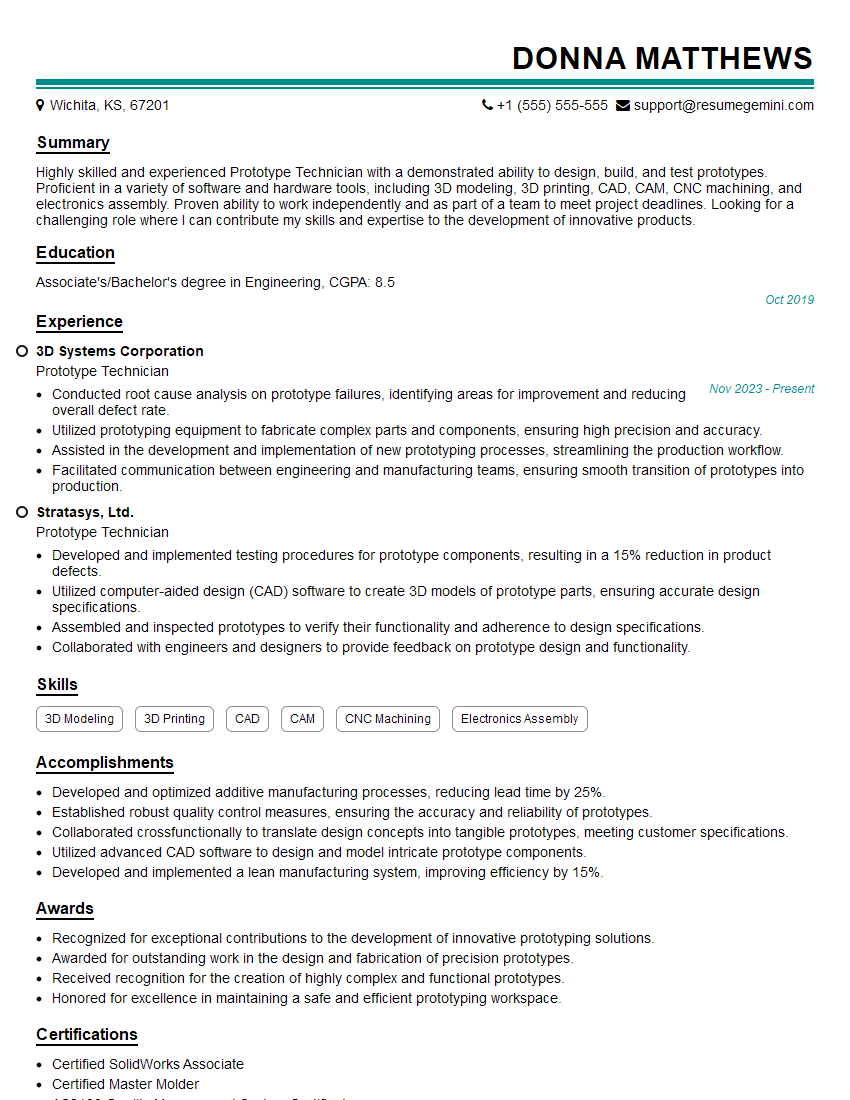

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Prototype Technician

1. What are the different types of prototyping and which one would you use for a given project?

There are various prototyping techniques, including:

- Rapid prototyping (RP): Using 3D printing or CNC machining to quickly create physical prototypes.

- Subtractive prototyping: Using milling or CNC machining to remove material from a solid block to create the prototype.

- Additive prototyping: Using 3D printing or similar technologies to build the prototype layer by layer.

- Hybrid prototyping: Combining multiple techniques to create the prototype.

The choice of prototyping technique depends on factors like:

- Complexity of the design

- Required accuracy and precision

- Material properties

- Time and cost constraints

2. What is the importance of tolerance analysis and how do you apply it in your work?

Understanding Tolerance Analysis

- Tolerance analysis is crucial for ensuring the proper fit and function of components in a prototype.

- It involves calculating the potential variations in dimensions and how they affect the overall assembly.

Applying Tolerance Analysis

- I use industry-standard software and analytical techniques to determine the tolerances required for each part.

- Consider factors like material properties, manufacturing processes, and assembly methods.

- Ensure that the tolerances specified on the design drawings are realistic and achievable.

- Monitor the tolerance analysis throughout the design and manufacturing process to identify potential issues.

3. How do you ensure the accuracy and precision of your prototypes?

I follow a rigorous quality control process to guarantee the accuracy and precision of prototypes:

- Use calibrated and precision measuring equipment to check dimensions and tolerances.

- Implement inspection plans to verify the quality of materials and components.

- Employ statistical process control techniques to monitor and improve accuracy over time.

- Regularly review and update quality standards to ensure compliance.

4. What materials are you familiar with and how do you select the appropriate material for a given project?

- Metals: Stainless steel, aluminum, brass, titanium, etc. for strength, durability, and corrosion resistance.

- Plastics: ABS, polycarbonate, nylon, etc. for lightweight, flexibility, and cost-effectiveness.

- Composites: Carbon fiber, fiberglass, etc. for high strength-to-weight ratios and durability.

- Ceramics: Alumina, zirconia, etc. for high temperature resistance and wear resistance.

I carefully consider factors like:

- Mechanical properties (strength, stiffness, hardness)

- Thermal properties (temperature resistance, conductivity)

- Electrical properties (conductivity, insulation)

- Chemical properties (corrosion resistance, biocompatibility)

- Cost and availability

5. What software do you use for prototyping and how do you stay up-to-date with the latest design and manufacturing technologies?

- CAD software: SolidWorks, Inventor, Creo, etc. for 3D modeling and design.

- Simulation software: ANSYS, COMSOL, etc. for analyzing the performance of designs.

- CAM software: MasterCAM, Esprit, etc. for generating CNC toolpaths.

I stay updated through:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and communities.

- Collaborating with experts in the field.

6. How do you communicate and collaborate effectively with engineers and designers during the prototyping process?

- Regular meetings and discussions to clarify requirements and design intent.

- Use of project management tools (e.g., Jira, Asana) to track progress and identify potential roadblocks.

- Sharing prototypes and design iterations for feedback and review.

- Providing technical support and guidance to ensure smooth collaboration.

7. How do you manage multiple projects simultaneously and prioritize tasks effectively?

- Using project management techniques (e.g., Gantt charts) to plan and track project progress.

- Prioritizing tasks based on urgency and dependencies.

- Delegating tasks to team members when necessary.

- Effective time management and organizational skills.

8. What are your strengths and weaknesses as a Prototype Technician?

Strengths:

- Expertise in prototyping techniques and materials.

- Strong understanding of tolerance analysis and quality control.

- Proficient in CAD, CAM, and simulation software.

- Excellent communication and collaboration skills.

Weaknesses:

- Limited experience with certain specialized prototyping technologies.

- Balancing multiple projects and meeting deadlines can sometimes be challenging.

9. How do you handle setbacks and unexpected challenges during the prototyping process?

- Evaluate the situation and identify the root cause of the problem.

- Explore alternative solutions and consult with experts if necessary.

- Document lessons learned and implement improvements to prevent similar issues in the future.

- Maintain a positive attitude and focus on finding solutions.

10. What motivates you and what do you enjoy most about being a Prototype Technician?

- Being part of the innovation process and bringing new products to life.

- Solving technical challenges and finding creative solutions.

- Collaborating with a diverse team of engineers and designers.

- Seeing the impact of my work on the success of new products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Prototype Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Prototype Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Prototype Technicians are responsible for designing and developing prototypes of products, parts, or components. They work closely with engineers and designers to turn concepts and design specifications into physical models. The key responsibilities of a Prototype Technician include:

1. Design and Development

Prototype Technicians use their knowledge of engineering principles and manufacturing processes to design and develop prototypes. They create detailed drawings, specifications, and procedures for the fabrication and assembly of prototypes.

- Interpret design specifications, drawings, and sketches.

- Use CAD software to create 3D models and technical drawings.

2. Fabrication and Assembly

Prototype Technicians fabricate and assemble prototypes using a variety of tools and equipment. They may use 3D printers, CNC machines, or hand tools to create parts and components. They also assemble prototypes according to design specifications and test them for functionality.

- Select and use appropriate tools and equipment.

- Fabricate parts and components using a variety of materials.

- Assemble prototypes according to design specifications.

3. Testing and Evaluation

Prototype Technicians test and evaluate prototypes to ensure that they meet design specifications. They may conduct functional tests, performance tests, or environmental tests. They also provide feedback to engineers and designers on the performance of prototypes.

- Conduct functional tests, performance tests, and environmental tests.

- Analyze test results and provide feedback to engineers and designers.

4. Documentation

Prototype Technicians document the design, fabrication, and testing of prototypes. They may create technical reports, drawings, and specifications. They also maintain records of all prototype development activities.

- Create technical reports, drawings, and specifications.

- Maintain records of all prototype development activities.

Interview Tips

Preparing for an interview for a Prototype Technician position can be daunting, but following these tips will help you ace it:

1. Research the Company and Position

Before your interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, mission, and goals. It will also help you tailor your answers to the specific requirements of the position.

- Visit the company’s website to learn about their products and services.

- Read industry publications and news articles to stay up-to-date on the latest trends.

- Review the job description carefully and identify the key qualifications.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Prepare answers to questions about your skills and experience.

- Practice describing your experience with specific projects and prototypes.

- Prepare questions to ask the interviewer.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing appropriate clothing that is clean and pressed. You should also avoid wearing excessive jewelry or makeup.

4. Be Punctual

Punctuality is important for any interview, but it is especially important for a Prototype Technician position. This shows that you are organized and respectful of others’ time.

5. Be Enthusiastic and Passionate

Prototype Technicians are passionate about their work. This is evident in the way they talk about their projects, the way they approach challenges, and the way they interact with others. If you are passionate about prototyping, make sure it shines through during your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Prototype Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!