Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Pulp Mill Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Pulp Mill Operator so you can tailor your answers to impress potential employers.

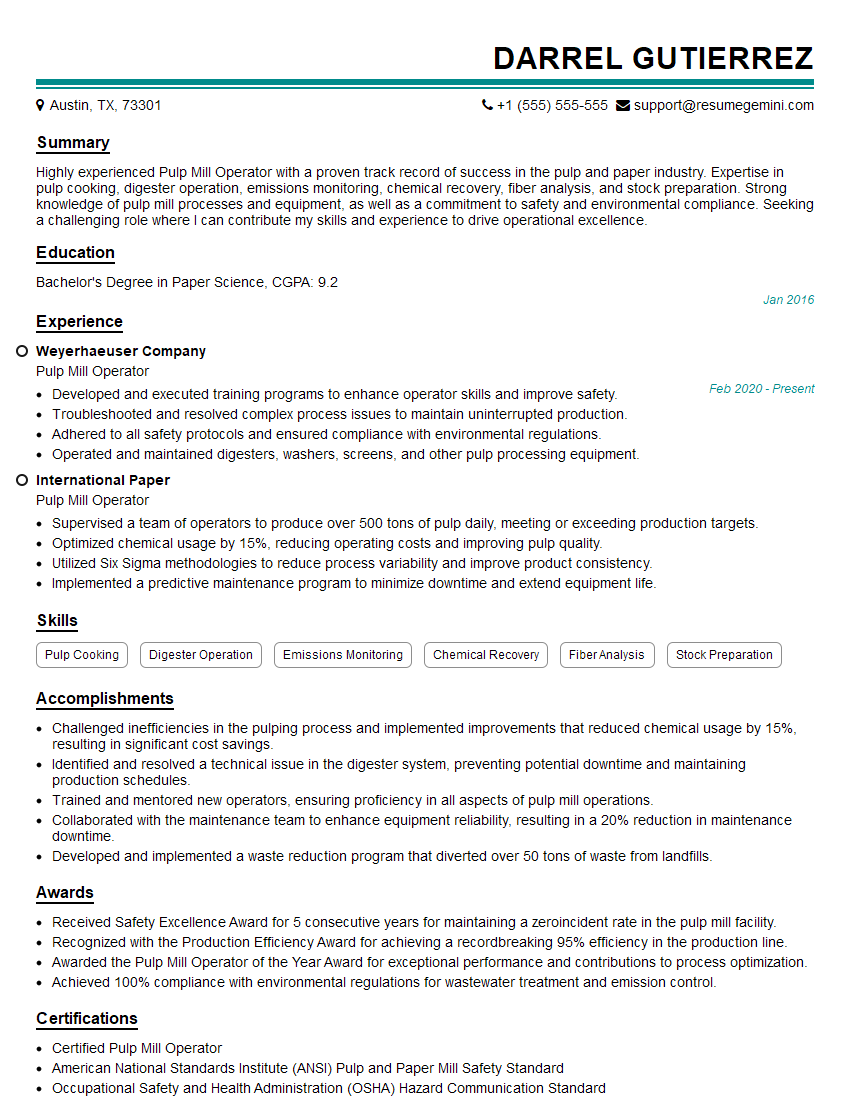

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pulp Mill Operator

1. Explain the process of chemical pulping?

Chemical pulping is a process of removing lignin from wood to produce pulp. The most common chemical pulping processes are the kraft process and the sulfite process.

- Kraft process: The kraft process is the most widely used chemical pulping process. It uses a mixture of sodium hydroxide (NaOH) and sodium sulfide (Na2S) to dissolve the lignin in wood. The kraft process produces a strong, durable pulp that is suitable for a variety of paper products, including printing and writing paper, packaging paper, and paperboard.

- Sulfite process: The sulfite process uses a mixture of sulfurous acid (H2SO3) and sodium sulfite (Na2SO3) to dissolve the lignin in wood. The sulfite process produces a pulp that is weaker than kraft pulp, but it is also brighter and more easily bleached. Sulfite pulp is typically used for making printing and writing paper.

2. What are the different types of digesters used in chemical pulping?

- Batch digesters: Batch digesters are large vessels that are filled with wood chips and cooking liquor. The digester is then heated and pressurized, and the cooking liquor dissolves the lignin in the wood. Batch digesters are typically used for the kraft process.

- Continuous digesters: Continuous digesters are long, cylindrical vessels that are continuously fed with wood chips and cooking liquor. The wood chips are gradually cooked as they move through the digester, and the lignin is dissolved in the cooking liquor. Continuous digesters are typically used for the sulfite process.

3. What are the key factors that affect the quality of pulp?

- Wood quality: The quality of the wood used for pulping has a significant impact on the quality of the pulp. Factors such as the species of wood, the age of the wood, and the presence of knots and other defects can all affect the pulp quality.

- Cooking conditions: The cooking conditions, such as the temperature, pressure, and duration of the cook, also have a significant impact on the pulp quality. The cooking conditions must be carefully controlled to ensure that the lignin is dissolved without damaging the cellulose fibers.

- Washing and screening: The pulp must be washed and screened to remove any remaining lignin and other impurities. The washing and screening process also helps to improve the brightness and cleanliness of the pulp.

4. What are the common problems that can occur in a pulp mill?

- Digester problems: Digester problems can include leaks, corrosion, and blockages. These problems can lead to reduced pulp production and quality.

- Washing and screening problems: Washing and screening problems can include clogged screens, broken wires, and poor washing efficiency. These problems can lead to increased pulp contamination and reduced pulp quality.

- Environmental problems: Pulp mills can generate a variety of environmental pollutants, including air pollution, water pollution, and solid waste. These pollutants can have a negative impact on the environment and human health.

5. What are the safety precautions that must be followed in a pulp mill?

- Wear appropriate personal protective equipment (PPE): PPE includes items such as safety glasses, gloves, and hard hats. PPE helps to protect workers from the hazards of pulp mill work, such as chemicals, noise, and moving machinery.

- Follow all safety procedures: Safety procedures are in place to protect workers from injury. It is important to follow all safety procedures, even if they seem inconvenient.

- Be aware of your surroundings: Be aware of the hazards around you and take steps to avoid them. This includes being aware of moving machinery, hot surfaces, and chemical spills.

6. What is the role of a pulp mill operator?

The role of a pulp mill operator is to operate and maintain the equipment used in a pulp mill. This includes digesters, washers, screens, and other equipment.

- Operate equipment: Pulp mill operators are responsible for operating a variety of equipment, including digesters, washers, screens, and other equipment. They must be able to start, stop, and adjust the equipment as needed.

- Monitor equipment: Pulp mill operators are responsible for monitoring the equipment to ensure that it is operating properly. They must be able to identify and troubleshoot any problems that occur.

- Maintain equipment: Pulp mill operators are responsible for maintaining the equipment to ensure that it is in good working order. This includes cleaning, lubricating, and repairing the equipment as needed.

7. What are the qualifications for a pulp mill operator?

- High school diploma or equivalent: A high school diploma or equivalent is typically required for pulp mill operators.

- Experience in a pulp mill: Experience in a pulp mill is preferred, but not required. This experience can be gained through internships, apprenticeships, or previous employment.

- Mechanical aptitude: Pulp mill operators must have a mechanical aptitude and be able to understand and operate a variety of equipment.

- Strong safety orientation: Pulp mill operators must have a strong safety orientation and be able to follow all safety procedures.

8. What is the work environment of a pulp mill operator?

The work environment of a pulp mill operator is typically a noisy, wet, and dirty environment.

- Noise: Pulp mills are noisy environments due to the operation of machinery and equipment.

- Wet: Pulp mills are wet environments due to the use of water in the pulping process.

- Dirty: Pulp mills are dirty environments due to the presence of wood chips, pulp, and other materials.

9. What are the benefits of working as a pulp mill operator?

- Job security: The pulp and paper industry is a stable industry, and pulp mill operators typically have job security.

- Good wages: Pulp mill operators typically earn good wages, especially those with experience and skills.

- Benefits: Pulp mill operators typically receive a variety of benefits, including health insurance, retirement benefits, and paid time off.

10. What are the challenges of working as a pulp mill operator?

- The work environment: The work environment of a pulp mill operator can be challenging due to the noise, wetness, and dirt.

- The physical demands: The work of a pulp mill operator can be physically demanding, as it involves lifting, carrying, and operating heavy equipment.

- The safety hazards: Pulp mills are hazardous environments, and pulp mill operators must be aware of the safety hazards and take precautions to avoid injury.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pulp Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pulp Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pulp Mill Operators are responsible for operating and monitoring pulp mill equipment to produce paper pulp. They ensure that the equipment is operating efficiently and safely, and that the pulp meets quality standards. Key job responsibilities include:

1. Operating pulp mill equipment

Pulp Mill Operators operate a variety of equipment to produce pulp, including digesters, washers, and screens. They must be familiar with the operation of this equipment and be able to troubleshoot any problems that may arise.

- Starting, stopping, and monitoring the operation of digesters, washers, and screens

- Adjusting process variables to maintain pulp quality

- Troubleshooting and repairing equipment

2. Monitoring pulp quality

Pulp Mill Operators must monitor the quality of the pulp produced to ensure that it meets customer specifications. They must be able to identify any defects in the pulp and take corrective action.

- Testing the pulp for brightness, strength, and other quality parameters

- Identifying and correcting any defects in the pulp

- Maintaining records of pulp quality

3. Maintaining a safe work environment

Pulp Mill Operators must maintain a safe work environment for themselves and their colleagues. They must be aware of the hazards associated with working in a pulp mill and take appropriate precautions.

- Following safety procedures

- Wearing personal protective equipment

- Keeping the work area clean and organized

4. Other responsibilities

Pulp Mill Operators may also be responsible for performing other tasks, such as:

- Cleaning and maintaining equipment

- Assisting with repairs

- Working with other departments to ensure smooth operation of the mill

Interview Tips

Preparing for an interview for a Pulp Mill Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and the specific requirements of the job. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your work history, your skills, and your accomplishments. If you have any experience in the pulp and paper industry, be sure to highlight it.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What are the opportunities for advancement within the company?”

- “What is the company’s culture like?”

5. Follow up

After the interview, be sure to follow up with the interviewer. Thank them for their time and express your interest in the position. You can also use this opportunity to reiterate your qualifications and to answer any questions that the interviewer may have forgotten to ask.

Next Step:

Now that you’re armed with the knowledge of Pulp Mill Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Pulp Mill Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini