Are you gearing up for a career in Rod Mill Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rod Mill Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

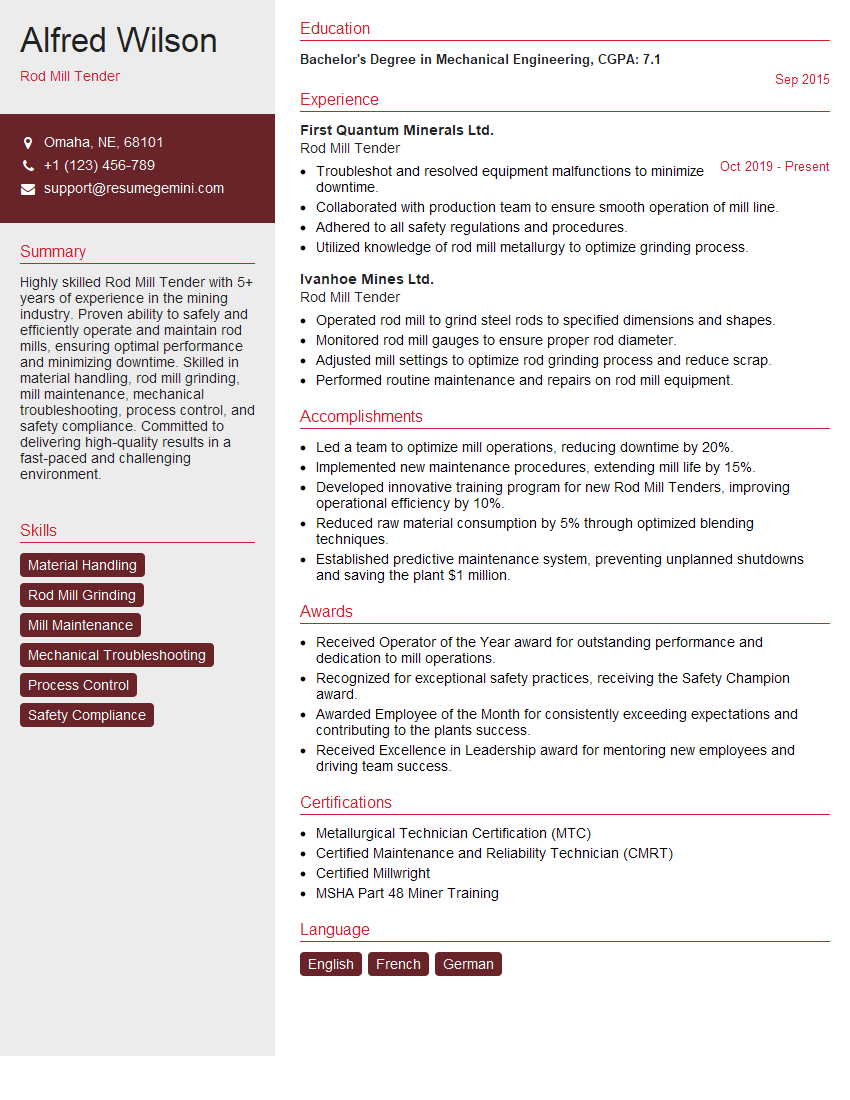

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rod Mill Tender

1. Describe the key responsibilities of a Rod Mill Tender.

As a Rod Mill Tender, my primary responsibilities include:

- Operating and monitoring rod mills to ensure efficient grinding of metal rods

- Adjusting mill settings, such as speed, feed rate, and water flow, to optimize production

- Monitoring and maintaining mill equipment, including lubrication, inspection, and repairs

- Ensuring the quality of the finished product by conducting regular inspections and tests

- Maintaining a clean and safe work environment in accordance with established safety protocols

2. Explain the process of rod mill operation, focusing on the following aspects:

a) Feed rate control

- Feed rate is critical in rod mill operation, and I adjust it based on factors such as mill load, feed size, and desired product size.

- I continuously monitor the feed rate and make adjustments as needed to ensure optimal grinding efficiency and product quality.

b) Water addition

- Water is added to the mill to reduce friction, cool the grinding media, and transport the ground material.

- I carefully control the amount of water added to maintain the desired slurry consistency and prevent over-grinding.

c) Mill speed

- Mill speed directly affects the grinding intensity and product size.

- I adjust the mill speed based on the desired product specifications and the characteristics of the feed material.

d) Grinding media selection and maintenance

- The selection and maintenance of grinding media are crucial for efficient rod mill operation.

- I inspect the grinding media regularly and replace worn or damaged media to ensure optimal grinding efficiency.

3. Describe the procedures you follow to ensure the quality of the finished product from the rod mill.

To ensure the quality of the finished product, I follow these procedures:

- Regularly sampling and testing the product to meet specified size and quality requirements

- Monitoring mill operating parameters and making adjustments as needed to maintain consistent product quality

- Inspecting the mill and grinding media for wear or damage, and taking corrective action when necessary

- Adhering to established quality control protocols and maintaining accurate records

4. Explain how you troubleshoot common problems encountered in rod mill operation.

Common problems encountered in rod mill operation include:

- Oversized product: I adjust feed rate, mill speed, or water addition to optimize grinding efficiency.

- Undersized product: I increase mill speed or grinding media size to achieve the desired product size.

- Excessive wear on grinding media: I inspect the media for damage, adjust mill operating parameters, or replace worn media.

- Blockages in the mill: I stop the mill, clear the blockage, and inspect for any underlying issues.

5. Describe the maintenance procedures you perform on rod mill equipment, focusing on the following aspects:

a) Lubrication

- I regularly lubricate all moving parts of the rod mill, including bearings, gears, and couplings.

- I follow established lubrication schedules and use the recommended lubricants to ensure optimal equipment performance.

b) Inspection

- I conduct regular inspections of the rod mill and its components to identify potential issues.

- I inspect for wear, damage, or misalignment, and take corrective action as necessary.

c) Repairs

- When repairs are necessary, I follow established procedures and use appropriate tools and techniques.

- I prioritize safety and ensure that all repairs are carried out correctly to prevent further issues.

6. Discuss the safety precautions you observe while working with rod mills.

Safety is paramount while working with rod mills, and I strictly adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, earplugs, and protective clothing

- Following lockout/tagout procedures before performing any maintenance or repairs

- Maintaining a clean and organized work area to prevent accidents

- Being aware of the location of emergency stop buttons and evacuation routes

- Receiving regular safety training and refresher courses

7. Describe your knowledge of different types of rod mills, including their advantages and disadvantages.

I am familiar with various types of rod mills, including:

- Grate-discharge rod mills: Advantages include efficient grinding, high capacity, and coarse product discharge; disadvantages include limited ability to produce fine products and higher energy consumption.

- Overflow-discharge rod mills: Advantages include ability to produce finer products, lower energy consumption, and reduced wear on mill lining; disadvantages include lower capacity and potential for product contamination.

- Semi-autogenous rod mills (SAG mills): Advantages include high reduction ratios, low power consumption, and ability to process large feed sizes; disadvantages include higher wear on mill lining and potential for product contamination.

8. Explain the factors that affect the efficiency of a rod mill.

The efficiency of a rod mill is influenced by several factors, including:

- Feed rate and size

- Mill speed and power

- Water addition

- Grinding media selection and size

- Mill design and configuration

- Maintenance and operating conditions

9. Describe how you would optimize the performance of a rod mill for a specific application.

To optimize the performance of a rod mill for a specific application, I would:

- Determine the desired product size and quality

- Select the appropriate mill type and configuration

- Adjust operating parameters (feed rate, mill speed, water addition) based on feed characteristics

- Monitor mill performance and make adjustments as needed

- Perform regular maintenance to ensure optimal equipment operation

10. Discuss the latest advancements in rod mill technology and their potential impact on the industry.

Recent advancements in rod mill technology include:

- Variable-speed drives to optimize mill performance

- Advanced control systems for automated operation

- Improved grinding media materials for increased efficiency and wear resistance

- These advancements have the potential to improve production efficiency, reduce energy consumption, and enhance product quality in the industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rod Mill Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rod Mill Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rod Mill Tenders are responsible for the operation and maintenance of rod mills in a mineral processing plant. Their primary duties involve overseeing the grinding process, ensuring equipment safety, and performing routine maintenance tasks.

1. Mill Operation

They operate rod mills, which grind large rocks into smaller particles. This process is crucial for preparing ore for further processing.

- Monitors mill feed rate, power draw, and particle size to ensure efficient grinding.

- Adjusts mill settings and controls to optimize performance and meet production targets.

2. Equipment Maintenance

Rod Mill Tenders perform preventive maintenance to keep mills in optimal condition and prevent breakdowns.

- Inspects and lubricates mill components, including bearings, gears, and motors.

- Replaces worn or damaged parts, such as liners and grinding rods.

3. Safety and Environmental Compliance

They ensure the safety of equipment and the surrounding environment during mill operation.

- Conducts regular safety inspections of mills and associated equipment.

- Follows environmental regulations and minimizes dust and noise emissions from the milling process.

4. Process Control

Rod Mill Tenders monitor the grinding process and make adjustments to ensure consistent particle size and product quality.

- Analyzes sample particles to determine particle size distribution.

- Adjusts mill operating parameters (e.g., feed rate, water flow) to achieve desired particle size.

Interview Tips

To ace an interview for a Rod Mill Tender position, candidates should prepare thoroughly and demonstrate:

1. Technical Knowledge

Candidates should be familiar with rod mill operation principles, maintenance procedures, and safety protocols.

- Research rod mill technology and grinding processes.

- Practice describing mill components and their functions.

2. Practical Experience

Highlight relevant experience in operating and maintaining rod mills or similar industrial equipment.

- Quantify your experience in mill operation, including production rates and downtime reduction.

- Emphasize your ability to troubleshoot and resolve mill issues.

3. Safety and Compliance

Demonstrate a strong understanding of safety regulations and environmental compliance as they relate to rod mill operation.

- Familiarize yourself with OSHA regulations and industry best practices for mill safety.

- Discuss your experience in implementing environmental controls and minimizing emissions.

4. Communication and Teamwork

Rod Mill Tenders often work with operators and maintenance personnel.

- Showcase your ability to communicate effectively with colleagues and supervisors.

- Highlight your experience in working as part of a team to achieve shared goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rod Mill Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!