Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rubber Mold Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

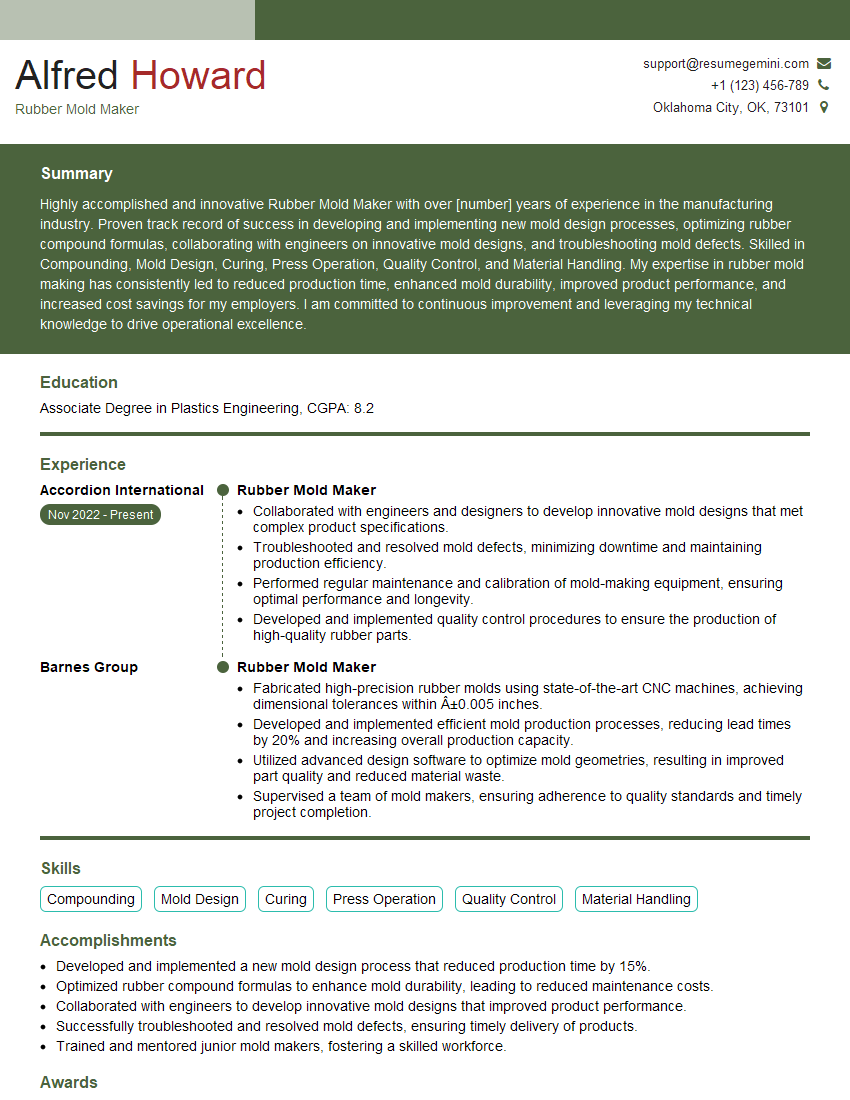

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Mold Maker

1. What are the different types of rubber used in mold making?

- Natural Rubber

- Synthetic Rubber

- Silicone Rubber

2. What are the factors that affect the quality of a rubber mold?

Material Selection

- Type of rubber

- Hardness

- Elasticity

Mold Design

- Geometry

- Draft angles

- Parting lines

Mold Making Process

- Mixing and pouring

- Curing

- Post-curing

3. What is the difference between a positive and negative mold?

- Positive Mold: Produces parts with the same shape as the mold.

- Negative Mold: Produces parts with the opposite shape of the mold.

4. What are the advantages and disadvantages of using rubber molds?

Advantages

- Versatility

- Low cost

- Easy to use

Disadvantages

- Limited durability

- Shrinkage during curing

- Can be affected by temperature and chemicals

5. What are the different applications of rubber molds?

- Prototyping

- Manufacturing of rubber parts

- Casting of metals and plastics

- Food industry

6. What is the process of making a rubber mold?

- Design the mold

- Select the appropriate rubber

- Mix and pour the rubber into the mold

- Cure the rubber

- Post-cure the rubber

7. What are the common problems encountered in rubber mold making?

- Air bubbles

- Shrinkage

- Warping

- Adhesion

8. How can you troubleshoot common problems encountered in rubber mold making?

- Air bubbles: Use a vacuum chamber or degas the rubber.

- Shrinkage: Use a higher quality rubber or adjust the curing process.

- Warping: Use a stiffer rubber or reinforce the mold.

- Adhesion: Use a release agent or modify the rubber formulation.

9. What are the safety precautions that must be taken when working with rubber molds?

- Wear gloves and safety glasses.

- Use proper ventilation.

- Handle chemicals safely.

- Dispose of waste properly.

10. What is your experience with rubber mold making?

- Describe your previous projects.

- Highlight your skills and knowledge.

- Explain how your experience makes you a suitable candidate for this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Rubber Mold Maker plays a critical role in the manufacturing process by creating high-quality molds used to produce rubber products. Their key responsibilities include:1. Mold Design and Creation

Designing and creating molds using computer-aided design (CAD) software, taking into account product specifications, material properties, and production requirements.

2. Patternmaking

Developing patterns using various materials such as wood, metal, or composite materials to create the base shape of the mold.

3. Mold Fabrication

Fabricating molds using rubber molding materials such as silicone, polyurethane, or epoxy, ensuring precise dimensions and smooth surfaces.

4. Mold Testing and Inspection

Testing molds to verify their accuracy and functionality by injecting rubber material and inspecting the resulting products for defects or imperfections.

5. Mold Maintenance and Repair

Performing preventive maintenance on molds to ensure their longevity, and repairing or rebuilding molds as needed to maintain production efficiency.

6. Collaboration and Communication

Collaborating with engineers, designers, and production teams to ensure molds meet specifications and contribute to overall product quality.

Interview Tips

To ace the interview for a Rubber Mold Maker position, candidates should prepare thoroughly by considering the following tips:1. Research the Company and Role

Thoroughly research the company’s history, products, and industry standing. Understand the specific responsibilities and expectations for the Rubber Mold Maker role.

2. Highlight Relevant Skills and Experience

Emphasize your skills in mold design, patternmaking, mold fabrication, and mold testing. Showcase any experience in the rubber molding industry or related fields.

3. Demonstrate Problem-Solving Abilities

Provide examples of how you have successfully identified and resolved issues related to mold design or fabrication. Highlight your analytical and troubleshooting skills.

4. Discuss Quality Control and Attention to Detail

Stress your commitment to quality and attention to detail in all aspects of mold making. Explain how you ensure the accuracy and precision of your work.

5. Be Prepared for Technical Questions

Review basic principles of mold design, rubber molding materials, and quality control techniques. Be ready to answer questions about your knowledge of mold making processes.

6. Show Enthusiasm and Passion

Convey your enthusiasm for the field of mold making and your passion for creating high-quality products. Express your interest in contributing to the company’s success.

Additionally, candidates should prepare by:- Practicing answering common interview questions

- Dressing professionally and arriving on time

- Asking thoughtful questions to demonstrate interest and engagement

Next Step:

Now that you’re armed with the knowledge of Rubber Mold Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rubber Mold Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini