Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Screed Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

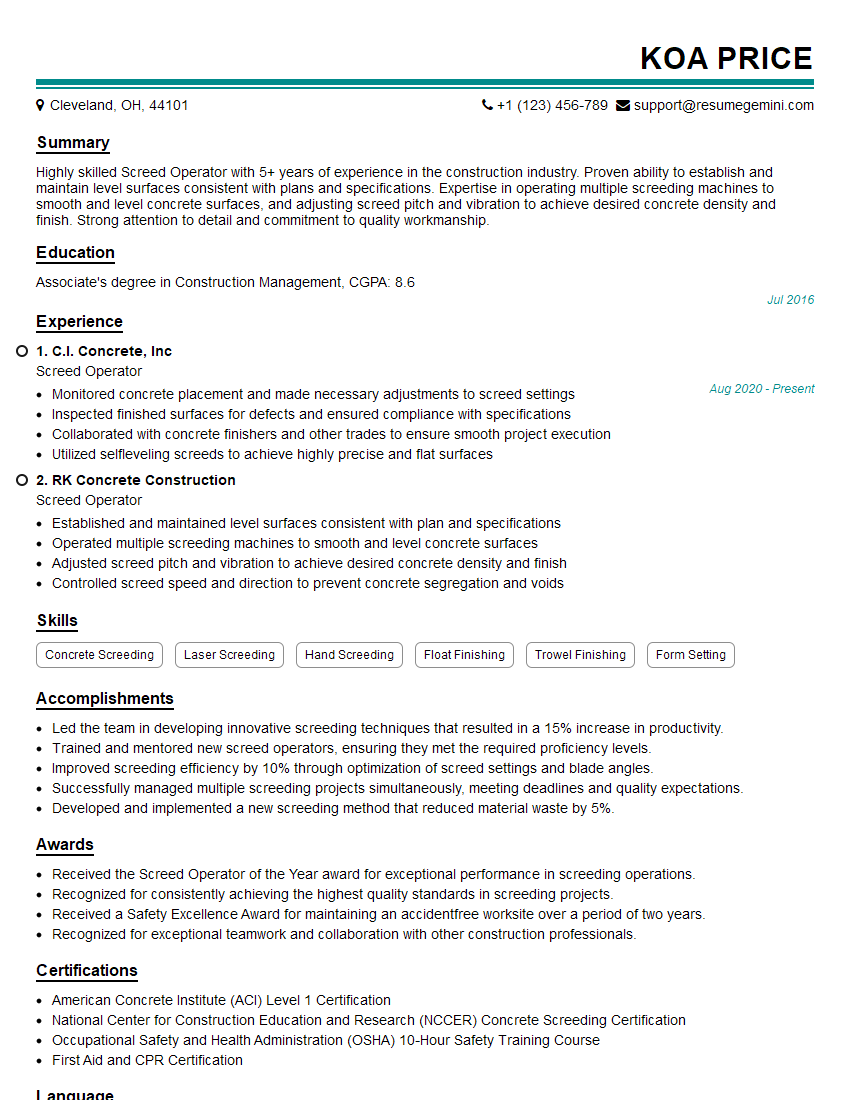

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Screed Operator

1. Explain the key responsibilities of a Screed Operator?

As a Screed Operator, my responsibilities include:

- Preparing and maintaining the screed machine to ensure optimal performance

- Operating the screed machine to level and smooth concrete surfaces

- Monitoring the concrete mix and adjusting screed settings to achieve the desired finish

- Inspecting the finished surface for quality and compliance with specifications

- Collaborating with other crew members to ensure efficient and safe operations

2. Describe the different types of screed machines and their applications?

Hydraulic Screeds

- Powered by hydraulics, providing precise control for high-quality finishes

- Suitable for large-scale projects, such as highway paving and airport runways

Mechanical Screeds

- Operated mechanically, offering versatility and ease of use

- Ideal for smaller projects, such as driveways, patios, and sidewalks

Laser Screeds

- Utilize laser technology to guide the screed, ensuring a level and precise finish

- Commonly used for indoor and outdoor applications, including commercial and industrial floors

3. Explain the factors that affect the quality of a concrete finish?

The quality of a concrete finish depends on several factors, including:

- Concrete mix design and consistency

- Proper screed operation and technique

- Environmental conditions, such as temperature, humidity, and wind

- Surface preparation, including curing and drying

- Experience and skill of the Screed Operator

4. Describe the safety precautions that should be taken when operating a screed machine?

Operating a screed machine requires adherence to the following safety precautions:

- Wearing appropriate personal protective equipment (PPE), including hard hat, safety glasses, gloves, and dust mask

- Ensuring the machine is properly grounded and maintained

- Inspecting the work area for hazards, such as overhead obstructions and uneven surfaces

- Following proper operating procedures and staying clear of moving parts

- Communicating effectively with other crew members to avoid accidents

5. Explain how you would troubleshoot and resolve common problems encountered during screeding operations?

Common problems encountered during screeding operations and their troubleshooting steps include:

- Uneven surface: Adjust screed settings, check concrete mix, and inspect for obstructions on the screed blades

- Tearing or cracking: Reduce screed speed, adjust concrete mix, and ensure proper curing

- Excessive vibration: Inspect screed blades for damage, check hydraulic system, and balance the machine

- Stalling: Ensure adequate power supply, check engine oil levels, and inspect for mechanical issues

6. Describe the techniques used to create different concrete finishes, such as exposed aggregate or stamped concrete?

To create different concrete finishes:

- Exposed aggregate: Use a retarder to prevent the top layer of concrete from setting, then wash away the surface later to reveal the aggregate

- Stamped concrete: Apply a release agent and use stamps to imprint a pattern into the freshly placed concrete

- Broom finish: Brush the surface of the concrete with a broom to create a textured finish

- Polished concrete: Grind and polish the concrete surface to achieve a smooth, glossy finish

7. Explain the importance of proper concrete curing and how it affects the finished product?

Proper concrete curing ensures:

- Increased strength and durability

- Reduced shrinkage and cracking

- Improved resistance to wear and abrasion

Curing methods include:

- Spraying with water

- Covering with plastic sheeting

- Using curing compounds

8. Describe how you would maintain and calibrate a screed machine to ensure optimal performance?

To maintain and calibrate a screed machine:

- Inspect and clean the machine regularly

- Lubricate moving parts and check hydraulic system

- Calibrate the laser level, if applicable, using a level or transit

- Adjust the screed blades and ensure they are properly aligned

- Follow the manufacturer’s recommended maintenance schedule

9. Explain the importance of teamwork and communication in screeding operations?

Teamwork and communication are crucial in screeding operations:

- Ensuring efficient workflow and avoiding delays

- Coordinating with concrete delivery trucks and other crew members

- Communicating potential hazards or equipment issues

- Maintaining a positive and respectful work environment

- Working together to produce high-quality concrete finishes

10. Describe your experience with different types of concrete mixes and how they affect the screeding process?

My experience with different concrete mixes includes:

- Regular concrete: Most common type, suitable for general construction projects

- High-strength concrete: Used for structures requiring exceptional strength and durability

- Self-leveling concrete: Flows easily, reducing the need for extensive screeding

- Fiber-reinforced concrete: Contains fibers to increase strength and reduce cracking

- Decorative concrete: Used for aesthetic purposes, with various colors and textures

Different mixes require adjustments in screed settings and techniques to achieve optimal results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Screed Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Screed Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Responsibilities Screed operators are responsible for operating screeds, which are machines used to level and smooth concrete surfaces. Their key responsibilities include:1. Prepare Surfaces for Screeding

– Ensuring the surface is level, graded, and free of obstructions – Setting up forms and guides for the screed to follow2. Operate Screed Machine

– Guiding the screed machine along the forms and guides – Adjusting the screed to achieve the desired level and smoothness – Ensuring the screed is moving at the correct speed and rate3. Finish Surface

– Polishing and troweling the surface to remove imperfections – Applying sealants and curing compounds to protect the concrete4. Maintain Equipment

– Inspecting and cleaning the screed machine regularly – Performing minor repairs and adjustments as needed5. Safety and Compliance

– Adhering to safety regulations and wearing appropriate protective gear – Complying with environmental regulations and disposing of waste materials properly ## Interview Tips 1. Research the Company and Role – Visit the company website to learn about their history, values, and products/services – Analyze the job description carefully to understand the specific requirements and expectations 2. Practice Common Interview Questions – Prepare answers to common interview questions, such as: – Tell me about yourself – Why are you interested in this role? – What are your strengths and weaknesses? – What experience do you have with screeding? 3. Highlight Relevant Skills and Experience – Emphasize your technical skills in operating screed machines and finishing concrete surfaces – Share examples of projects where you have demonstrated proficiency in these areas 4. Quantify Accomplishments – Use specific numbers and metrics to quantify your accomplishments, for example: – “Increased screeding efficiency by 15% by optimizing machine settings” 5. Demonstrate Teamwork and Communication – Explain how you work effectively with others on construction sites and maintain open communication 6. Be Prepared to Discuss Industry Trends – Show that you are aware of current industry trends and advancements in screeding technology 7. Ask Thoughtful Questions – Ask insightful questions to demonstrate your interest in the role and the company, such as: – “What are the company’s plans for future screeding projects?” – “Can you provide more details about the specific screed machine I will be using?”Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Screed Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.