Are you gearing up for an interview for a Sheet Metal Duct Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sheet Metal Duct Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

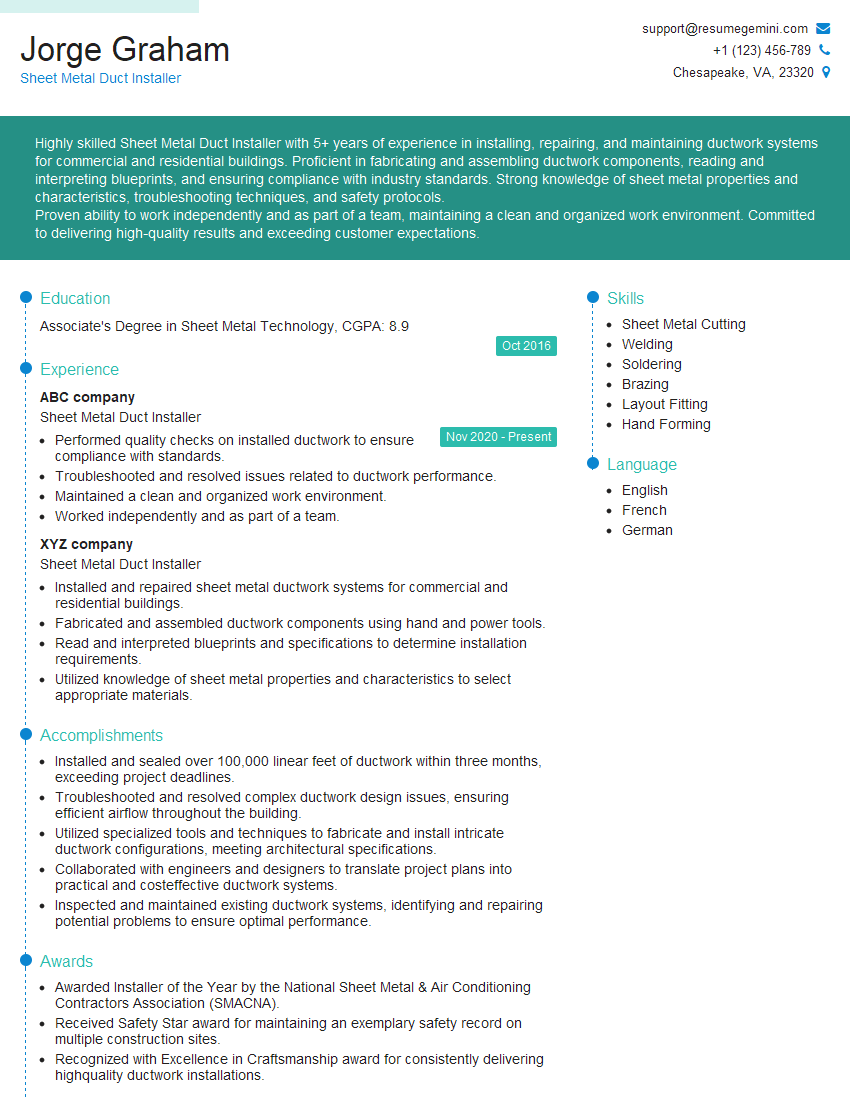

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Duct Installer

1. What are the different types of sheet metal duct joints that you are familiar with?

- Pittsburgh Lock Joint: This is a mechanically seamed joint that provides an airtight and strong connection.

- Slip Joint: A simple joint that allows for easy assembly and disassembly.

- Drive Cleat Joint: A joint that utilizes cleats to hold the duct sections together.

2. How would you calculate the square footage of a rectangular duct?

Formula: Square Footage = (Length x Width) x 2 + (Length x Height) x 2

Example:

- Length: 10 feet

- Width: 5 feet

- Height: 8 feet

- Square Footage = (10 x 5) x 2 + (10 x 8) x 2 = 300 square feet

3. What safety precautions should be observed when installing sheet metal ducts?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Use sharp cutting tools and handle them with care.

- Securely fasten the ductwork to prevent falls or damage.

- Follow manufacturer’s instructions and industry standards.

4. What tools and equipment are essential for sheet metal duct installation?

- Sheet metal shears

- Angle grinder

- Plasma cutter

- Drill

- Screwdriver

- Measuring tape

- Level

- Safety equipment

5. How do you determine the correct size and type of ductwork for a specific application?

- Consider the airflow requirements of the system.

- Calculate the static pressure loss of the system.

- Select the appropriate duct material based on the application.

- Size the ductwork according to industry standards and manufacturer’s specifications.

6. What techniques do you use to ensure proper airflow distribution in a duct system?

- Install dampers and balancing devices to regulate airflow.

- Use proper duct sizing and layout to minimize friction losses.

- Install diffusers and grilles to distribute airflow evenly.

- Test and balance the system to ensure optimal performance.

7. How do you troubleshoot common sheet metal duct installation issues, such as leaks and noise?

- Inspect joints for gaps or improper sealing.

- Apply sealant or gaskets as needed.

- Check for holes or tears in the ductwork.

- Identify the source of the noise (e.g., loose components, vibration).

- Install vibration isolators or sound-absorbing materials.

- Adjust the ductwork to minimize turbulence.

Leaks

Noise

8. What maintenance and inspection procedures are recommended for sheet metal duct systems?

- Regular cleaning to remove dust and debris.

- Inspect joints, seals, and components for damage or wear.

- Check airflow and static pressure to ensure optimal performance.

- Document maintenance and inspection activities for future reference.

9. What is your experience with working on commercial or industrial ductwork projects?

I have extensive experience in commercial and industrial ductwork projects, including:

- Installation of large-scale ductwork systems for hospitals, schools, and office buildings.

- Fabrication and installation of custom ductwork components.

- Troubleshooting and repair of complex ductwork systems.

10. What are some of the challenges you have faced in the field of sheet metal duct installation, and how did you overcome them?

One of the challenges I faced was installing a complex ductwork system in a tight space. To overcome this, I carefully planned the layout, utilized specialized fabrication techniques, and worked closely with other trades to ensure a successful installation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Duct Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Duct Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Duct Installers play a crucial role in the construction and maintenance of heating, ventilation, and air conditioning (HVAC) systems. Their primary responsibilities include:

1. Installation and Assembly

Install and assemble sheet metal ducts, fittings, and components using hand tools, power tools, and welding equipment.

- Read blueprints and specifications to determine the layout and dimensions of duct systems.

- Cut, shape, and form sheet metal using shears, brakes, and rolls.

2. Fabrication and Welding

Fabricate and weld ductwork to meet specific design requirements.

- Operate welding equipment to join sheet metal components.

- Inspect and test welds for quality and proper strength.

3. Maintenance and Repairs

Perform maintenance and repairs on existing duct systems.

- Troubleshoot and diagnose problems with HVAC systems.

- Replace or repair damaged ducts, fittings, and components.

4. Safety and Regulations

Follow all safety regulations and industry standards.

- Wear appropriate personal protective equipment (PPE).

- Handle and store hazardous materials safely.

Interview Tips

To ace the interview for a Sheet Metal Duct Installer position, it is crucial to prepare thoroughly and showcase your skills and experience.

1. Research the Company and Position

Before the interview, take the time to research the company and specific job requirements. This will help you understand the company’s culture, values, and the scope of the role.

- Visit the company’s website and social media pages.

- Review the job description carefully and note the key skills and qualifications.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. This will help you articulate your thoughts clearly and confidently.

- Prepare examples of your relevant skills and experience.

- Practice answering questions about your knowledge of sheet metal duct installation and fabrication techniques.

3. Highlight Your Safety Awareness

Emphasize your commitment to safety in your answers. This is a critical aspect of this role.

- Describe your experience with handling and storing hazardous materials.

- Discuss your knowledge of OSHA regulations and safety protocols.

4. Be Enthusiastic and Motivated

Demonstrate your enthusiasm for the HVAC industry and your motivation to succeed in this role.

- Explain why you are interested in a career as a Sheet Metal Duct Installer.

- Share any relevant experience or training programs you have completed.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Duct Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!