Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sheet Metal Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

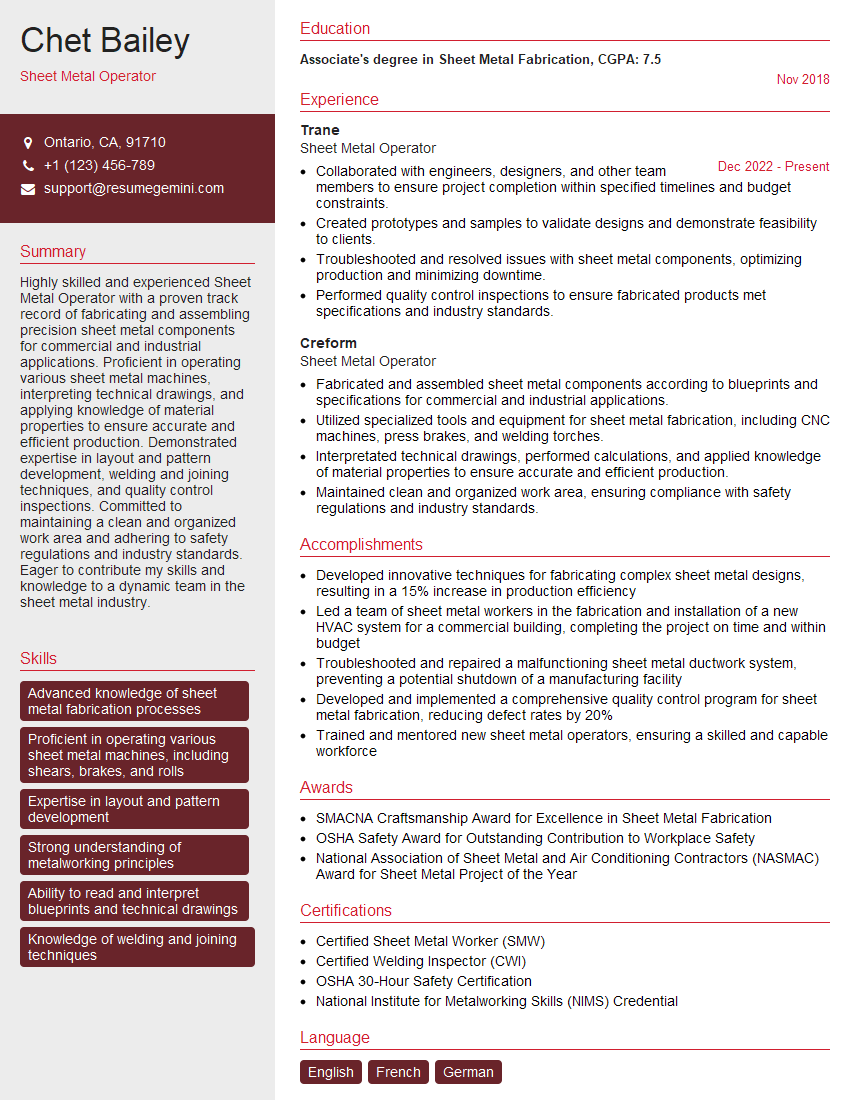

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Operator

1. What are the different types of sheet metal gauges and their uses?

There are various types of sheet metal gauges, each with its own thickness and application. Some common gauges include:

- 24-gauge: Used for thin, lightweight applications such as vents and light fixtures.

- 20-gauge: Commonly used for gutters, downspouts, and roofing.

- 18-gauge: Suitable for heavier applications, such as ductwork and metal siding.

- 16-gauge: Widely used for structural applications such as framing and supports.

- 14-gauge: Ideal for heavy-duty applications, such as machine guards and building exteriors.

2. Explain the process of layout and fabrication of a sheet metal component.

The process involves several steps:

Layout:

- Reading engineering drawings to understand the component’s design.

- Creating a layout on the sheet metal, marking bend lines, cutouts, and holes.

Fabrication:

- Using shears or CNC machines to cut the sheet metal to the desired shape.

- Bending the metal using press brakes or other bending equipment.

- Creating holes using punches or laser cutting.

- Assembling components using welding, rivets, or screws.

3. Describe the different types of sheet metal forming techniques and their applications.

Various sheet metal forming techniques include:

- Rolling: Used to create cylindrical or conical shapes, such as pipes and tanks.

- Bending: Used to create angles and curves, such as in ductwork and roofing.

- Stamping: Used to produce high-volume, repetitive parts by pressing the metal into a die.

- Drawing: Used to create deep, drawn shapes, such as cups and pans.

- Spinning: Used to create symmetrical, rotational shapes, such as lampshades and cookware.

4. What are the common safety precautions to follow when operating sheet metal machinery?

Safety is paramount when operating sheet metal machinery. Some key precautions include:

- Wearing appropriate safety gear, including gloves, eye protection, and earplugs.

- Ensuring proper machine guarding to prevent contact with moving parts.

- Following lockout/tagout procedures before performing maintenance or repairs.

- Maintaining a clean and organized work area.

- Receiving proper training and certification on specific machinery.

5. How do you ensure the accuracy and quality of the final sheet metal product?

Accuracy and quality are crucial:

- Accurate measurements: Using precision measuring tools and following drawings precisely.

- Proper setup: Ensuring that machinery is calibrated and set up correctly.

- Quality control: Regularly inspecting parts throughout the fabrication process.

- Testing: Conducting tests to verify the product meets specifications.

- Continuous improvement: Seeking ways to optimize processes and enhance quality.

6. Explain the different types of welding processes used in sheet metal fabrication.

Common welding processes include:

- MIG welding (GMAW): Uses a consumable wire fed through a welding gun.

- TIG welding (GTAW): Uses a non-consumable tungsten electrode and a shielding gas.

- Spot welding: Creates localized welds using high-current pulses.

- Arc welding (SMAW): Uses a consumable electrode covered in flux.

- Laser welding: Utilizes a high-power laser to fuse metal.

7. Describe the different types of sheet metal finishing techniques and their applications.

Various finishing techniques enhance aesthetics and functionality:

- Painting: Provides a protective and decorative coating.

- Powder coating: Electrostatically applies a durable, corrosion-resistant finish.

- Anodizing: Creates a protective oxide layer on aluminum.

- Galvanizing: Coats steel with zinc to enhance corrosion resistance.

- Plating: Deposits a thin layer of metal, such as chrome or nickel, for decorative or functional purposes.

8. How do you interpret sheet metal blueprints and drawings?

Understanding blueprints is essential for accurate fabrication:

- Symbols and abbreviations: Familiarizing oneself with industry-standard symbols.

- Dimensions and tolerances: Reading and interpreting measurements and allowable variations.

- Material specifications: Identifying the type, thickness, and grade of sheet metal.

- Fabrication instructions: Following the steps and sequences outlined in the drawings.

9. What are some tips for maximizing efficiency and minimizing waste in sheet metal fabrication?

Optimizing processes reduces costs and improves productivity:

- Material utilization: Planning layouts to minimize scrap and maximize material usage.

- Tooling selection: Using the right tools for the job, such as sharp punches and dies.

- Process automation: Utilizing CNC machinery and automated systems.

- Inventory management: Maintaining adequate inventory levels to avoid delays.

- Preventive maintenance: Regularly servicing and calibrating machines to minimize breakdowns.

10. How do you troubleshoot common problems that may arise during sheet metal fabrication?

Problem-solving is crucial for uninterrupted production:

- Dimensional inaccuracies: Checking measurements, tooling, and machine settings.

- Tearing or buckling: Adjusting feed rates, tooling angles, or using thicker material.

- Welding defects: Ensuring proper joint preparation, welding parameters, and shielding gas.

- Surface imperfections: Identifying the cause, such as improper cleaning, tooling wear, or material scratches.

- Equipment malfunctions: Diagnosing and addressing issues promptly to minimize downtime.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Operators are responsible for a wide range of tasks in the fabrication and assembly of sheet metal products. These tasks typically include:

1. Reading and interpreting blueprints and specifications

Sheet Metal Operators must be able to clearly understand and follow instructions in order to accurately fabricate and assemble sheet metal products.

- Interpreting blueprints to determine the dimensions, materials, and fabrication techniques required for a particular product.

- Ensuring the specifications are properly followed and that all components are manufactured to the correct tolerances.

2. Operating sheet metal machinery

Sheet Metal Operators use a variety of machines to fabricate and assemble sheet metal products. These machines include:

- Shears to cut sheet metal to the desired size and shape

- Presses to bend and form sheet metal into the desired shape.

- Welders to join sheet metal components together.

- Having a thorough understanding of the capabilities and limitations of each machine.

- Performing regular maintenance and calibration of equipment to ensure it is operating properly.

3. Fabricating sheet metal products

Sheet Metal Operators fabricate sheet metal products according to the blueprints and specifications. These products can include a wide variety of items, such as:

- Ductwork for heating and air conditioning systems

- Roofs and siding for buildings

- Automotive parts

- Electronic enclosures

- Following established quality control procedures to ensure that all products meet the required standards.

- Working with other team members to complete projects on time and within budget.

4. Assembling sheet metal products

Sheet Metal Operators assemble sheet metal products by joining the individual components together. This can be done using a variety of methods, such as:

- Welding

- Riveting

- Screwing

- Adhesives

- Ensuring that all joints are strong and secure.

- Inspecting the finished product to ensure that it meets the required quality standards.

Interview Preparation Tips

If you follow the tips given below, it can help you perform better in your upcoming interview for the position of Sheet Metal Operator.

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. You should also learn as much as you can about the specific role you are applying for. This will help you answer interview questions intelligently and show that you are genuinely interested in the position.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

- Network with people in your field to learn about potential job openings.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What is your experience with sheet metal fabrication?”

- “What are your salary expectations?”

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time to show that you are respectful of the interviewer’s time.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Arrive at the interview location 10-15 minutes early.

4. Be confident and enthusiastic

Interviewers are looking for candidates who are confident and enthusiastic about the job. Show the interviewer that you are interested in the position and that you have the skills and experience to be successful.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about your work.

5. Follow up after the interview

After your interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are serious about your application. You can follow up by sending a thank-you note or by email.

- Send a thank-you note within 24 hours of the interview.

- Reiterate your interest in the position.

- Thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!