Feeling lost in a sea of interview questions? Landed that dream interview for Ship Propeller Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ship Propeller Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

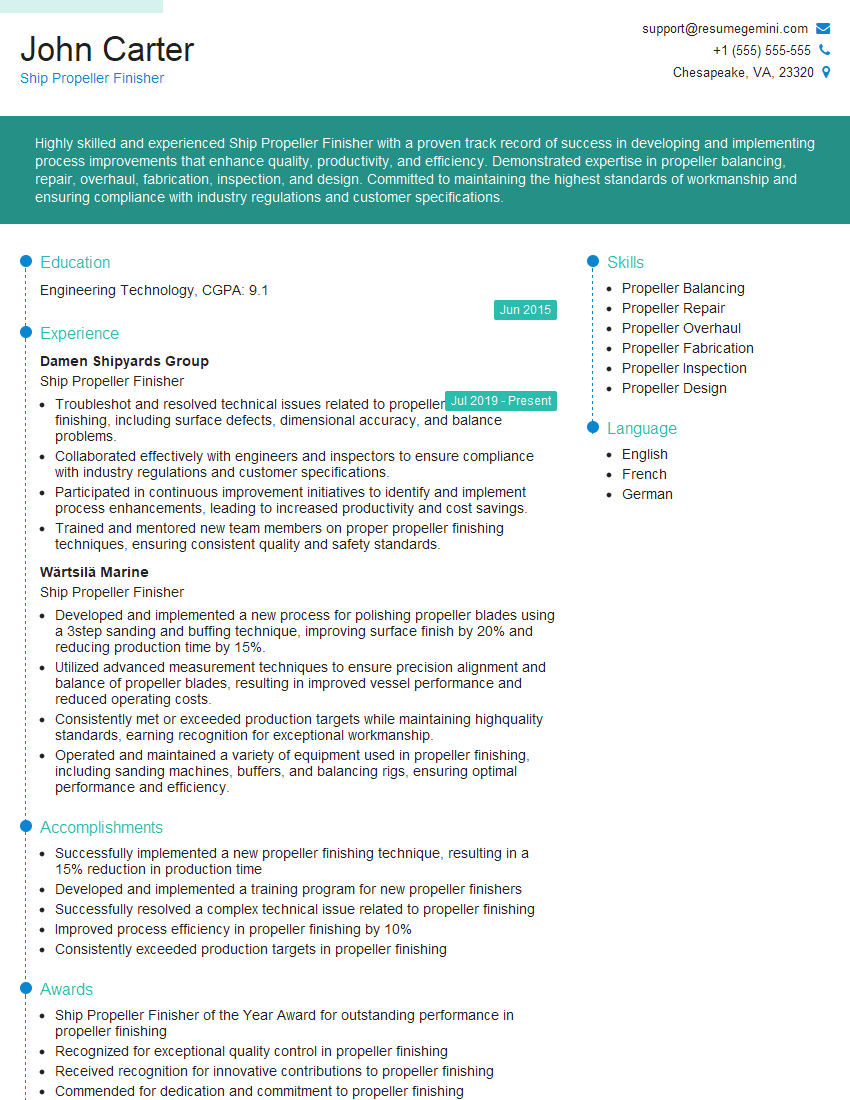

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ship Propeller Finisher

1. Describe the key steps involved in finishing a propeller?

Here are the key steps involved in finishing a ship propeller:

- Preparation: The propeller is cleaned, inspected, and any defects are repaired.

- Balancing: The propeller is balanced to ensure that it will run smoothly and without vibration.

- Coating: The propeller is coated with a protective layer to prevent corrosion and wear.

- Polishing: The propeller is polished to give it a smooth, finished surface.

- Inspection: The finished propeller is inspected to ensure that it meets all specifications.

2. What are the most common challenges in finishing a ship propeller?

Some of the most common challenges in finishing a ship propeller include:

- Achieving the desired surface finish: The propeller must have a smooth, polished surface to reduce drag and improve efficiency.

- Balancing the propeller: The propeller must be balanced to ensure that it will run smoothly and without vibration.

- Coating the propeller: The propeller must be coated with a protective layer to prevent corrosion and wear.

- Meeting the specifications: The finished propeller must meet all of the specifications required by the customer.

3. What are the different types of finishes that can be applied to a ship propeller?

The most common types of finishes that can be applied to a ship propeller include:

- Paint: Paint is a relatively inexpensive and easy-to-apply finish that can provide good protection against corrosion and wear.

- Electroplating: Electroplating is a process of coating a metal with a thin layer of another metal. Electroplating can provide good protection against corrosion and wear, and it can also improve the appearance of the propeller.

- Powder coating: Powder coating is a process of applying a dry powder to a metal surface and then curing the powder with heat. Powder coating can provide good protection against corrosion and wear, and it can also produce a variety of colors and finishes.

- Ceramic coating: Ceramic coating is a process of applying a thin layer of ceramic to a metal surface. Ceramic coating can provide excellent protection against corrosion and wear, and it can also improve the performance of the propeller.

4. What are the advantages and disadvantages of using different types of finishes on a ship propeller?

The advantages and disadvantages of using different types of finishes on a ship propeller include:

Paint

- Advantages: Paint is relatively inexpensive and easy to apply. It can provide good protection against corrosion and wear.

- Disadvantages: Paint can be easily damaged, and it may not provide the best protection against corrosion and wear in harsh environments.

Electroplating

- Advantages: Electroplating can provide good protection against corrosion and wear. It can also improve the appearance of the propeller.

- Disadvantages: Electroplating can be more expensive than other types of finishes. It can also be more difficult to apply, and it may not be suitable for all types of propellers.

Powder coating

- Advantages: Powder coating can provide good protection against corrosion and wear. It can also produce a variety of colors and finishes.

- Disadvantages: Powder coating can be more expensive than other types of finishes. It can also be more difficult to apply, and it may not be suitable for all types of propellers.

Ceramic coating

- Advantages: Ceramic coating can provide excellent protection against corrosion and wear. It can also improve the performance of the propeller.

- Disadvantages: Ceramic coating can be more expensive than other types of finishes. It can also be more difficult to apply, and it may not be suitable for all types of propellers.

5. What are the key factors to consider when selecting a finish for a ship propeller?

The key factors to consider when selecting a finish for a ship propeller include:

- The environment in which the propeller will be used: The propeller must be able to withstand the corrosive and wear-resistant environment in which it will be used.

- The performance requirements of the propeller: The finish must not adversely affect the performance of the propeller.

- The cost of the finish: The finish must be cost-effective.

- The appearance of the propeller: The finish must provide a desirable appearance for the propeller.

6. What are the latest trends in ship propeller finishing?

The latest trends in ship propeller finishing include:

- The use of new materials: New materials are being developed that offer better protection against corrosion and wear.

- The use of new technologies: New technologies are being developed that make it easier and more efficient to apply finishes to propellers.

- The development of new regulations: New regulations are being developed that require propellers to be finished in a more environmentally friendly manner.

7. What are the most important qualities of a good ship propeller finisher?

The most important qualities of a good ship propeller finisher include:

- Attention to detail: Ship propeller finishers must be able to pay close attention to detail in order to ensure that the propeller is finished to the highest possible standard.

- Skilled in the use of tools and equipment: Ship propeller finishers must be skilled in the use of the tools and equipment used to finish propellers.

- Knowledge of different types of finishes: Ship propeller finishers must have a good knowledge of the different types of finishes that can be applied to propellers.

- Experience in finishing propellers: Ship propeller finishers must have experience in finishing propellers in a variety of environments.

8. What is the future of ship propeller finishing?

The future of ship propeller finishing is bright. As new materials and technologies are developed, it will become possible to finish propellers in a more efficient and environmentally friendly manner. This will lead to better performance and longer life for propellers.

9. What is your favorite thing about working as a ship propeller finisher?

My favorite thing about working as a ship propeller finisher is the satisfaction of knowing that I am helping to keep ships running smoothly and efficiently. I also enjoy the challenge of working with different materials and technologies to create a finished product that meets the highest standards.

10. What is your proudest accomplishment as a ship propeller finisher?

My proudest accomplishment as a ship propeller finisher was finishing the propeller for a new cruise ship. The propeller was the largest I had ever worked on, and it was a challenge to get it finished on time and to the highest possible standard. However, I was able to complete the project successfully, and the ship was able to set sail on time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ship Propeller Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ship Propeller Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ship Propeller Finishers are responsible for the final finishing of ship propellers. They ensure that the propellers meet the required specifications and are free of defects. Their responsibilities include:

1. Grinding and polishing

Grind and polish propeller blades to achieve the desired surface finish and remove any burrs or imperfections. Also ensure that the blades are balanced and free of vibration.

- Use a variety of grinding and polishing tools and equipment.

- Follow established procedures and specifications for grinding and polishing.

2. Inspection and testing

Inspect propellers for defects such as cracks, porosity, and corrosion.

- Conduct non-destructive testing (NDT) on propellers to ensure their integrity.

- Record and report any defects found during inspection.

3. Assembly and installation

Assemble and install propellers on ships.

- Use specialized tools and equipment to assemble and install propellers.

- Follow established procedures and specifications for assembly and installation.

4. Maintenance and repair

Maintain and repair propellers to ensure their optimal performance.

- Inspect propellers for signs of wear and damage.

- Repair or replace damaged propeller blades as necessary.

Interview Tips

To ace the interview for a Ship Propeller Finisher position, candidates should be well-prepared and highlight their skills and experience in the following areas:

1. Technical skills

Candidates should demonstrate a strong understanding of the processes involved in propeller finishing, including grinding, polishing, inspection, and testing.

- Provide examples of their experience in using grinding and polishing tools and equipment.

- Explain their knowledge of non-destructive testing (NDT) methods and their experience in conducting NDT on propellers.

2. Attention to detail

Ship Propeller Finishers must have a keen eye for detail to ensure that propellers meet the required specifications and are free of defects.

- Highlight their experience in identifying and correcting defects in propellers.

- Provide examples of their commitment to quality and precision in their work.

3. Teamwork

Ship Propeller Finishers often work as part of a team to assemble and install propellers on ships.

- Describe their experience working in a team environment and their ability to collaborate with others.

- Highlight their communication and interpersonal skills.

4. Safety

Ship Propeller Finishers must follow established safety procedures and wear appropriate protective gear.

- Discuss their understanding of safety regulations and their commitment to maintaining a safe work environment.

- Provide examples of their experience in following safety protocols.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ship Propeller Finisher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.