Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sole Cementer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

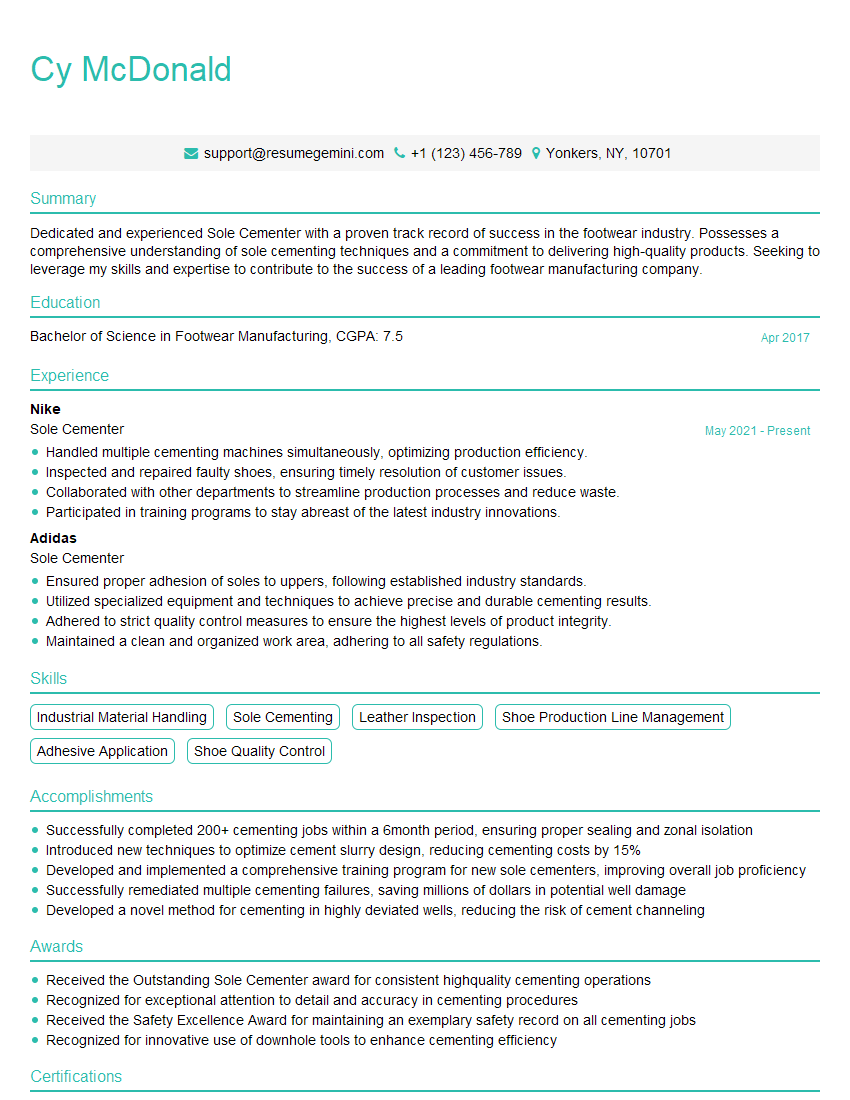

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sole Cementer

1. Describe the key responsibilities of a Sole Cementer.

- Laying and bonding cement in various types of projects, such as walls, floors, and foundations

- Mixing and preparing cement to ensure its quality and consistency

- Using different tools and techniques to apply cement, such as trowels, screeds, and floats

- Reading and interpreting blueprints and specifications

- Working independently and as part of a team

2. What are the different types of cement used in construction, and what are their properties?

- Portland cement: The most common type of cement, it is strong, durable, and resistant to fire and water

- Blended cement: A mixture of portland cement and other materials, such as fly ash or slag, it is less expensive than portland cement but has similar properties

- High-early-strength cement: A type of cement that gains strength quickly, it is used in projects where time is of the essence

- Masonry cement: A type of cement specifically designed for use in masonry projects, it is more flexible than portland cement

- White cement: A type of cement that is used for decorative purposes, it is more expensive than portland cement

3. What are the different methods of cement application, and when is each method used?

- Hand cementing: Using a trowel to apply cement, this method is used for small projects and for applying cement in tight spaces

- Machine cementing: Using a cement mixer to apply cement, this method is used for large projects where speed and efficiency are important

- Pneumatic cementing: Using a pneumatic cement gun to apply cement, this method is used for spraying cement onto surfaces

- Gunite cementing: Using a gunite machine to apply cement, this method is used for spraying cement onto surfaces at high pressure

- Shotcrete cementing: Using a shotcrete machine to apply cement, this method is used for spraying cement onto surfaces at very high pressure

4. What are the common problems that can occur during cementing, and how can they be prevented or corrected?

- Cracking: Can be caused by improper curing, excessive shrinkage, or thermal expansion

- Spalling: Can be caused by freezing and thawing cycles, or by the use of deicing salts

- Efflorescence: Can be caused by the presence of moisture and salts in the cement

- Discoloration: Can be caused by the use of certain types of cement or by the presence of impurities

- Corrosion: Can be caused by the presence of moisture and oxygen

5. What are the safety precautions that must be taken when working with cement?

- Wear protective clothing, such as gloves, goggles, and a dust mask

- Avoid contact with cement on your skin or in your eyes

- Do not ingest cement

- Work in a well-ventilated area

- Follow all manufacturer’s instructions for the safe use of cement

6. What is the difference between cement and concrete?

- Cement is a binding agent that is used to make concrete

- Concrete is a mixture of cement, sand, gravel, and water

- Concrete is stronger and more durable than cement

- Concrete is used in a wider variety of applications than cement

7. What is the role of cement in concrete?

- Cement binds the sand and gravel together to form a solid mass

- Cement provides strength and durability to concrete

- Cement helps to control the setting time of concrete

8. What are the different types of concrete?

- Normal-weight concrete: The most common type of concrete, it is used for a wide variety of applications

- Lightweight concrete: A type of concrete that is made with lightweight aggregates, it is used for applications where weight is a concern

- Heavyweight concrete: A type of concrete that is made with heavyweight aggregates, it is used for applications where strength and durability are important

- High-performance concrete: A type of concrete that is designed to meet specific performance requirements, it is used for applications where strength, durability, or other properties are critical

9. What are the different methods of concrete placement?

- Hand placement: Using buckets or shovels to place concrete, this method is used for small projects and for placing concrete in tight spaces

- Pumping: Using a concrete pump to place concrete, this method is used for large projects and for placing concrete at high elevations or long distances

- Conveying: Using a conveyor belt to place concrete, this method is used for large projects and for placing concrete over long distances

- Slipforming: Using a slipform paver to place concrete, this method is used for paving roads and other large flat surfaces

10. What are the common problems that can occur during concrete placement, and how can they be prevented or corrected?

- Segregation: Can be caused by improper mixing or placement of concrete, it can lead to a reduction in strength and durability

- Bleeding: Can be caused by an excess of water in the concrete mix, it can lead to a reduction in strength and durability

- Cold joints: Can be caused by placing concrete in layers that are too thick or that are not properly bonded together, it can lead to a reduction in strength and durability

- Honeycombing: Can be caused by improper consolidation of concrete, it can lead to a reduction in strength and durability

- Cracking: Can be caused by a variety of factors, including improper curing, shrinkage, or thermal expansion

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sole Cementer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sole Cementer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sole Cementer is responsible for cementing the soles of shoes. They work in a factory setting, using a variety of tools and materials to complete their tasks. Some of their key responsibilities include:

1. Preparing the shoes

Before cementing the soles, the shoes must be prepared. This may involve cleaning the soles, removing any old adhesive, and roughing up the surface to help the adhesive bond.

2. Applying the cement

Once the shoes are prepared, the cement is applied. The type of cement used will vary depending on the type of shoes and the material of the soles.

3. Attaching the soles

Once the cement has been applied, the soles are attached to the shoes. This is a delicate process that requires precision and accuracy.

4. Finishing the shoes

Once the soles are attached, the shoes are finished. This may involve trimming any excess cement and cleaning the shoes.

Interview Tips

To ace your interview for a Sole Cementer position, it’s important to be prepared and have a good understanding of the job responsibilities. Here are some tips to help you prepare:

1. Research the company

Before your interview, take some time to research the company. This will help you learn more about their products, their mission statement, and their values. You can find this information on the company’s website and social media pages.

2. Practice your answers

Once you have a good understanding of the job responsibilities and the company, it’s time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

3. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a clean, pressed suit or dress, and polished shoes.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. This will show the interviewer that you are respectful of their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sole Cementer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!