Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Steam Pipe Fitter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Steam Pipe Fitter so you can tailor your answers to impress potential employers.

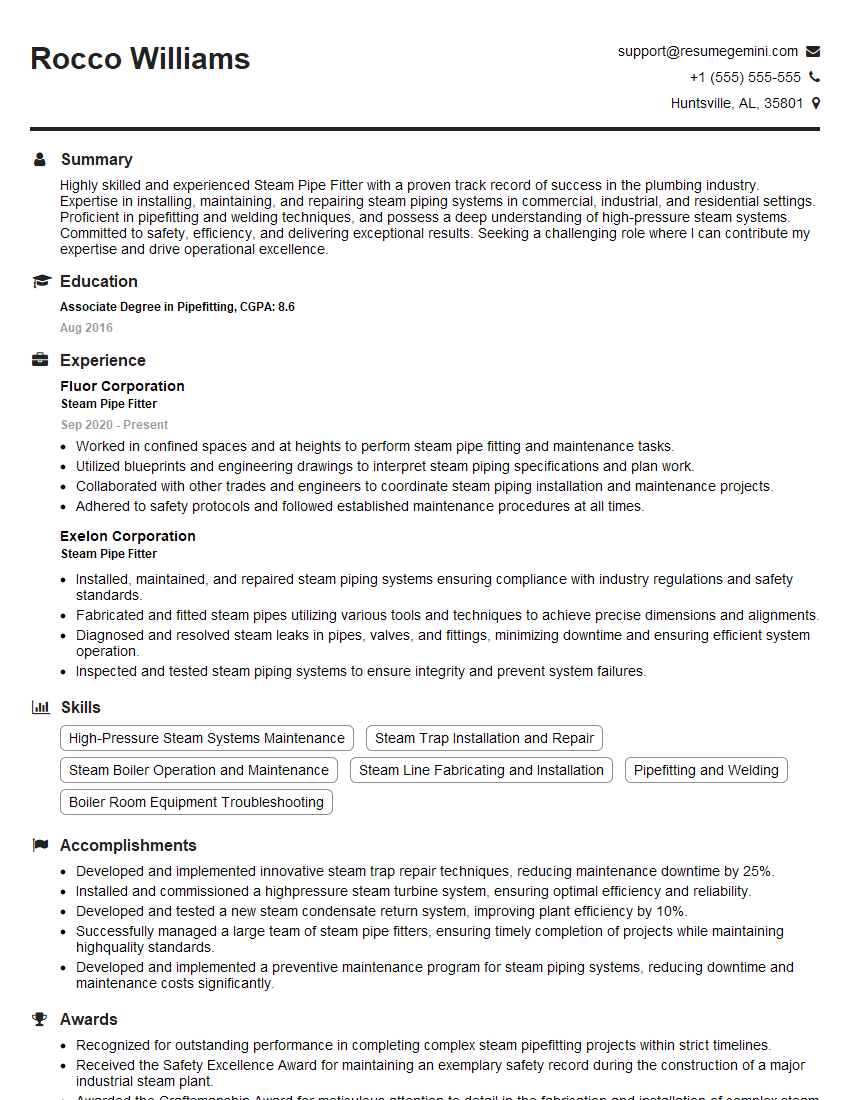

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steam Pipe Fitter

1. What are the different types of pipe hangers and supports used in steam piping systems, and what are their specific functions?

- Fixed supports: These supports prevent the pipe from moving in any direction and are typically used for vertical pipes or at changes in direction.

- Sliding supports: These supports allow the pipe to move axially while preventing lateral movement. They are typically used for horizontal pipes that are subject to thermal expansion.

- Spring supports: These supports absorb vibration and shock by using a spring or rubber element. They are typically used in areas with high vibration or where the pipe is subject to thermal expansion.

- Rod hangers: These hangers are used to support pipes from above and allow for vertical movement. They are typically used for small-diameter pipes or in areas where space is limited.

2. What are the different types of pipe fittings used in steam piping systems, and how are they used?

- Elbows: These fittings change the direction of the pipe by 90 or 45 degrees.

- Tees: These fittings create a branch in the pipe, allowing for the connection of a third pipe.

- Reducers: These fittings reduce the diameter of the pipe, allowing for the connection of smaller-diameter pipes.

- Unions: These fittings allow for the easy connection and disconnection of pipes. They are typically used for maintenance and repairs.

3. What are the different types of welding processes used in steam piping systems, and what are their advantages and disadvantages?

- Shielded metal arc welding (SMAW): This process is also known as stick welding and is the most common type of welding used in steam piping systems. It is relatively easy to learn and requires less expensive equipment than other welding processes.

- Gas tungsten arc welding (GTAW): This process uses a tungsten electrode and a shielding gas to create a weld. It produces high-quality welds but is more difficult to learn and requires more expensive equipment than SMAW.

- Gas metal arc welding (GMAW): This process uses a consumable electrode and a shielding gas to create a weld. It is faster than SMAW and GTAW but can be more difficult to control the weld quality.

4. What are the different types of pipe insulation used in steam piping systems, and what are their properties and applications?

- Mineral wool: This insulation is made of fiberglass or rock wool and is a good choice for high-temperature applications. It is also non-combustible and has good sound absorption properties.

- Cellular glass: This insulation is made of glass foam and is a good choice for low-temperature applications. It is also non-combustible and has good moisture resistance.

- Polystyrene: This insulation is made of plastic foam and is a good choice for medium-temperature applications. It is also lightweight and has good moisture resistance.

5. What are the different types of valves used in steam piping systems, and what are their functions?

- Gate valves: These valves are used to isolate a section of pipe for maintenance or repairs. They are fully open or fully closed and are not suitable for throttling.

- Globe valves: These valves are used to control the flow of steam by throttling it. They are also used as shut-off valves, but they are not as reliable as gate valves.

- Check valves: These valves allow steam to flow in one direction only. They are typically used to prevent backflow in steam lines.

6. What are the safety precautions that must be taken when working on steam piping systems?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Lock out and tag out steam piping systems before working on them.

- Use proper tools and techniques when working on steam piping systems.

- Be aware of the hazards associated with working on steam piping systems, such as hot surfaces and high pressure.

7. What are the different types of boilers used in steam piping systems, and what are their advantages and disadvantages?

- Fire-tube boilers: These boilers have the fire inside the tubes, and the water surrounds the tubes. They are less efficient than water-tube boilers but are less expensive to build.

- Water-tube boilers: These boilers have the water inside the tubes, and the fire surrounds the tubes. They are more efficient than fire-tube boilers but are more expensive to build.

8. What is the purpose of a steam trap in a steam piping system?

The purpose of a steam trap is to remove condensate from the steam piping system. Condensate is water that has formed due to the cooling of steam. If condensate is not removed, it can damage the piping system and reduce its efficiency.

9. What are the different types of steam traps available, and how do they work?

- Mechanical steam traps: These traps use a mechanical device to remove condensate. The most common type of mechanical steam trap is the float trap, which uses a float to open and close a valve.

- Thermostatic steam traps: These traps use a thermostatic element to remove condensate. The most common type of thermostatic steam trap is the bimetallic trap, which uses two metal strips with different expansion rates to open and close a valve.

10. What are the different types of steam piping systems, and what are their applications?

- Single-pipe steam systems: These systems use a single pipe to distribute steam and return condensate. They are typically used in small buildings or in areas where space is limited.

- Two-pipe steam systems: These systems use two pipes, one for distributing steam and the other for returning condensate. They are typically used in larger buildings or in areas where efficiency is important.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steam Pipe Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steam Pipe Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steam Pipe Fitters are responsible for the installation, maintenance, and repair of piping systems that transport steam. Their primary duties include:

1. Installation of Piping Systems

Install piping systems that convey steam, water, and other fluids in industrial and commercial buildings.

- Read and interpret blueprints and drawings

- Select and cut pipes to appropriate lengths

- Join pipes using welding, threading, or flanging

- Install valves, fittings, and other components

2. Maintenance and Repair of Piping Systems

Perform routine maintenance and repairs on piping systems to ensure their safe and efficient operation.

- Inspect piping systems for leaks, corrosion, or other damage

- Identify and fix leaks or other problems promptly

- Replace worn or damaged components

- Conduct regular maintenance checks

3. Testing and Inspection

Conduct pressure tests on piping systems to ensure their integrity and safety.

- Conduct visual inspections of piping systems

- Monitor pressure gauges and other instruments

- Report any problems or irregularities to supervisors

4. Safety Regulations and Codes

Follow all applicable safety regulations and codes when working on piping systems.

- Wear appropriate personal protective equipment

- Follow proper lockout/tagout procedures

- Use safe work practices and techniques

- Keep work area clean and organized

Interview Tips

To prepare for a Steam Pipe Fitter interview, it is important to:

1. Research the Company and Position

Familiarize yourself with the company’s website, products or services, and industry. This will help you understand the company’s culture, values, and specific requirements for the position.

2. Practice Answering Common Interview Questions

- Tell me about your experience in steam pipe fitting?

- What is your understanding of steam pipe fitting codes and regulations?

- Can you describe your experience with pressure testing and troubleshooting?

Highlight your skills, knowledge, and experience in installing, maintaining, and repairing steam piping systems.

Demonstrate your knowledge of the applicable safety codes and industry standards.

Explain your experience in conducting pressure tests to ensure system integrity and identifying and resolving problems.

3. Highlight Your Safety Knowledge and Practices

Emphasize your commitment to safety by describing your experience in following proper lockout/tagout procedures, using personal protective equipment, and maintaining a clean and organized work area.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and company. Prepare questions about the company’s growth plans, training opportunities, or specific projects you could contribute to.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Steam Pipe Fitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Steam Pipe Fitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.