Feeling lost in a sea of interview questions? Landed that dream interview for Steel Loader but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Steel Loader interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

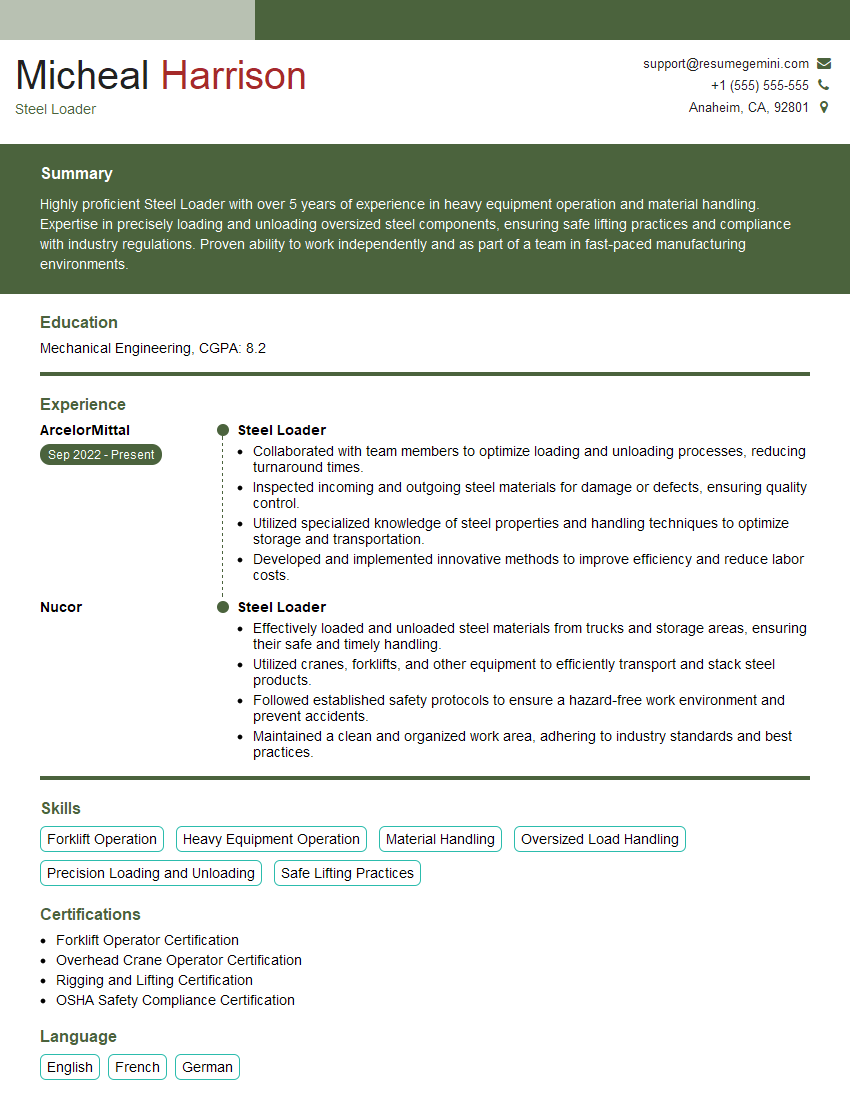

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Steel Loader

1. Can you describe the key components of a steel loading machine?

- Engine: Provides power to the machine for operation.

- Hydraulic system: Controls the movement of the loader’s arms and grapples.

- Loader arms: Extends and retracts to load and unload materials.

- Grapples: Attachments that securely hold steel materials during loading and unloading.

- Frame: Supports the entire machine and provides stability.

2. What safety protocols should be followed when operating a steel loader?

- Wear appropriate safety gear (e.g., hard hat, safety glasses, gloves).

- Inspect the machine before each use (e.g., hydraulics, grapples, tires).

- Ensure the work area is clear of obstacles and personnel.

- Follow proper lifting techniques to avoid strain or injury.

- Be aware of potential hazards (e.g., falling objects, slippery surfaces).

3. What factors influence the loading capacity of a steel loader?

- Loader model and specifications (e.g., hydraulic pressure, engine power).

- Type of steel being loaded (e.g., weight, shape, dimensions).

- Environmental conditions (e.g., temperature, wind).

- Operator experience and skill.

- Maintenance status of the loader.

4. How do you troubleshoot common issues with steel loaders?

- Hydraulic leaks: Inspect hoses and fittings for leaks, tighten connections.

- Grapple malfunctions: Check hydraulics, inspect teeth for wear, adjust or replace.

- Engine problems: Check oil and fuel levels, inspect spark plugs or filters.

- Electrical faults: Examine wiring, fuses, and connections.

- Tire issues: Check tire pressure, inspect for damage or leaks.

5. What maintenance tasks are essential for keeping a steel loader in optimal condition?

- Regular lubrication (e.g., greasing bearings, hydraulic lines).

- Hydraulic system checks (e.g., fluid level, pressure).

- Tire maintenance (e.g., inflation, inspections).

- Engine servicing (e.g., oil changes, filter replacements).

- Inspections for wear and tear (e.g., grapples, loader arms).

6. How do you calculate the weight of a steel load based on its dimensions and density?

7. How do you ensure the stability of a steel loader when handling heavy loads?

- Position the loader on a flat and stable surface.

- Balance the load evenly on the loader’s grapples.

- Extend the loader arms fully to distribute the weight.

- Engage the parking brake to prevent the loader from moving.

- Use outriggers or stabilizers if necessary.

8. What are the different types of steel loading attachments and how do you select the most appropriate for a specific task?

- Fork attachments: Suitable for handling pallets, crates, and other flat objects.

- Hook attachments: Used for lifting heavy beams, pipes, and other elongated materials.

- Grapple attachments: Ideal for handling loose or irregularly shaped materials.

- Magnet attachments: Designed for lifting magnetic materials.

- Coil grapples: Specifically designed for handling steel coils.

9. How do you safely store and handle steel materials to prevent damage or injury?

- Avoid stacking steel materials excessively high.

- Use proper slings or chains for lifting.

- Store steel in a dry and well-ventilated area to prevent corrosion.

- Protect steel from sharp edges or objects that could cause damage.

- Wear appropriate safety gear when handling steel.

10. What are the key performance indicators used to evaluate the efficiency of a steel loader operator?

- Load handling capacity (tons per hour).

- Cycle time (time required to complete a load-unload cycle).

- Safety record (absence of accidents or incidents).

- Equipment maintenance (keeping the loader in good working condition).

- Fuel efficiency (optimal fuel consumption).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Steel Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Steel Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Steel Loaders are responsible for loading, unloading, and transporting steel and other materials within a warehouse or industrial setting. They ensure that materials are safely and efficiently moved to their designated locations.

1. Loading and Unloading

Steel Loaders are responsible for operating forklifts, cranes, or other equipment to load and unload steel from trucks, trailers, or rail cars.

- Inspect steel materials for damage before loading or unloading

- Use proper techniques to safely lift, move, and secure steel

2. Material Handling

Steel Loaders are responsible for transporting steel within a warehouse or industrial setting using forklifts, cranes, or other equipment.

- Follow designated routes and safety protocols when transporting steel

- Ensure that steel is stored in designated areas and properly secured

3. Inventory Management

Steel Loaders are often responsible for maintaining inventory records and keeping track of steel stock levels.

- Use inventory management systems to track steel stock levels

- Monitor steel inventory and report any discrepancies or shortages

4. Equipment Maintenance

Steel Loaders are responsible for performing basic maintenance on equipment used to load, unload, and transport steel.

- Perform regular inspections and maintenance on forklifts, cranes, and other equipment

- Report any equipment malfunctions or safety concerns

Interview Tips

Preparing for an interview for a Steel Loader position can help you make a positive impression on the hiring manager and increase your chances of getting the job. Here are key tips:

1. Research the Company and Position

Researching the company and the specific Steel Loader position will help you understand the company’s culture, values, and the specific requirements of the role. This will enable you to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their mission, values, and products or services.

- Review the job description carefully to identify the key responsibilities and qualifications required for the position.

2. Practice Your Answers

Practicing your answers to common interview questions will help you feel more confident and prepared during the interview. Be prepared to answer questions about your experience, skills, and why you’re interested in the position.

- Prepare examples of your work experience that demonstrate your skills and abilities.

- Be able to articulate why you’re interested in working as a Steel Loader and what makes you a good fit for the position.

3. Dress Professionally

Dressing professionally for the interview shows that you respect the interviewer and the company. First impressions matter, so make sure you dress appropriately for the occasion.

- Wear clean, pressed clothing that is appropriate for a warehouse or industrial setting.

- Consider wearing safety shoes or boots, as you may be required to work in a warehouse environment.

4. Be Enthusiastic and Positive

Enthusiasm and a positive attitude can go a long way in an interview. Show the interviewer that you’re excited about the opportunity to work as a Steel Loader and that you’re eager to learn and contribute to the company.

- Be friendly and approachable, and make eye contact with the interviewer.

- Speak clearly and confidently, and be prepared to share your ideas and experiences.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Steel Loader, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Steel Loader positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.