Feeling lost in a sea of interview questions? Landed that dream interview for Stemming Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Stemming Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

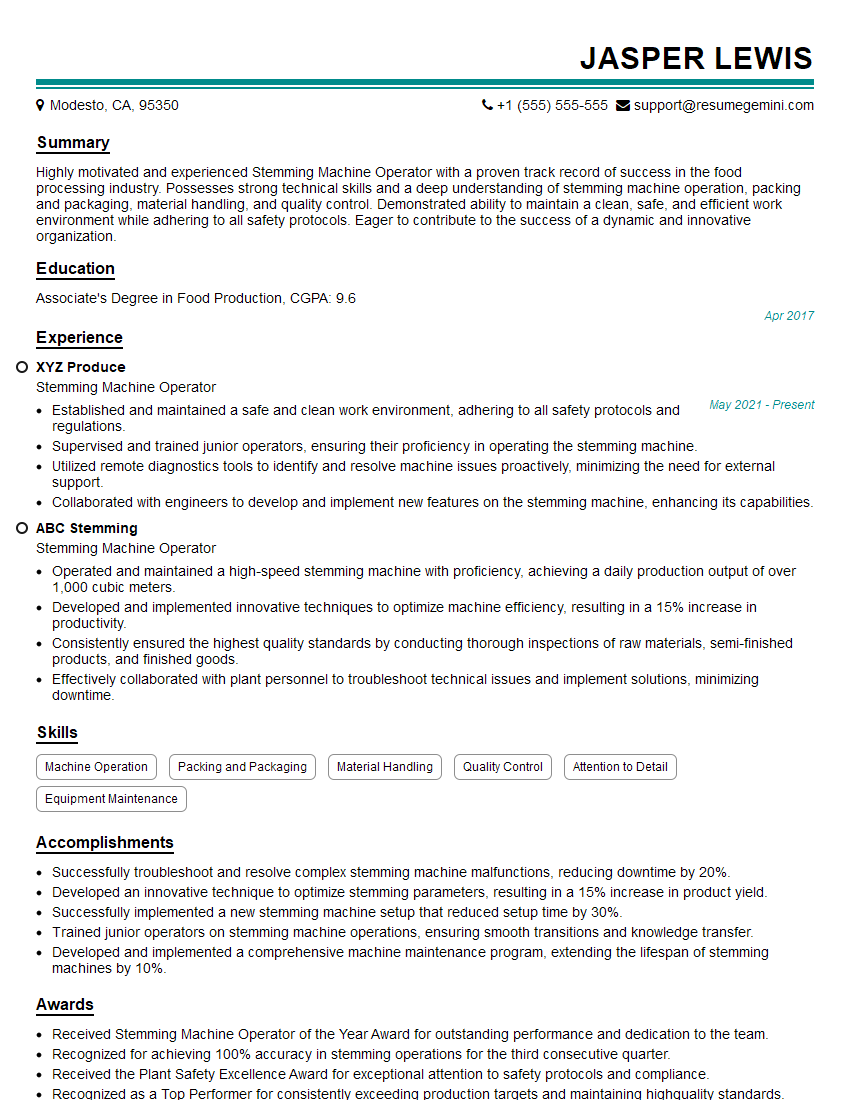

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stemming Machine Operator

1. Explain the principles of stemming operation?

Stemming is a process by which the explosive is removed from the borehole after blasting. The principles of stemming operation involve:

- Preparing the borehole for stemming by cleaning out any loose rock or debris.

- Inserting the stemming material into the borehole, taking care to fill it completely and tamp it down firmly.

- Placing a detonating cord or other ignition device into the stemming material.

- Firing the detonating cord or ignition device to detonate the stemming material and expel the explosive from the borehole.

2. Describe the different types of stemming materials and their properties?

Inert materials

- Sand

- Gravel

- Crushed rock

Reactive materials

- Water

- Foam

- Chemical grout

3. What are the factors that affect the choice of stemming material?

The choice of stemming material depends on several factors, including:

- The type of explosive being used

- The size and shape of the borehole

- The depth of the borehole

- The surrounding rock conditions

- The desired results

4. How do you determine the correct amount of stemming to use?

The amount of stemming to use depends on several factors, including:

- The size and shape of the borehole

- The type of explosive being used

- The desired results

In general, the amount of stemming should be at least twice the diameter of the borehole.

5. What are the safety precautions that must be taken when handling and using stemming materials?

- Stemming materials should be stored in a dry, well-ventilated area.

- Stemming materials should not be mixed with explosives.

- Stemming materials should not be used in areas where there is a risk of fire or explosion.

- Stemming materials should be handled and used only by trained personnel.

6. What are the common problems that can occur during stemming operation and how do you resolve them?

- Bridging: This occurs when the stemming material forms a bridge across the borehole, preventing the explosive from detonating properly. To resolve this, the stemming material should be tamped down firmly to ensure that it fills the borehole completely.

- Poor detonation: This can occur if the stemming material is not tamped down firmly enough or if the detonating cord or ignition device is not placed properly. To resolve this, the stemming material should be tamped down firmly and the detonating cord or ignition device should be checked to ensure that it is properly placed.

- Misfire: This occurs when the stemming material prevents the explosive from detonating. To resolve this, the stemming material should be removed from the borehole and the explosive should be checked to ensure that it is not damaged.

7. What are the quality control procedures that must be followed to ensure that stemming operations are performed correctly?

- The stemming material should be inspected to ensure that it is of the correct type and quality.

- The amount of stemming should be measured to ensure that it is sufficient.

- The stemming material should be tamped down firmly to ensure that it fills the borehole completely.

- The detonating cord or ignition device should be checked to ensure that it is properly placed.

- The stemming operation should be supervised by a trained and experienced person.

8. What are the environmental considerations that must be taken into account when performing stemming operations?

- Stemming materials should not be allowed to enter waterways or contaminate soil.

- Stemming materials should be disposed of properly.

- Stemming operations should be conducted in a manner that minimizes noise and dust.

9. What are the technological advancements that have been made in stemming operations?

- The use of electronic detonators has improved the accuracy and reliability of stemming operations.

- The use of down-the-hole hammers has made it possible to stem boreholes more quickly and efficiently.

- The development of new stemming materials has improved the safety and effectiveness of stemming operations.

10. What are the future trends in stemming operations?

- The use of automation and robotics in stemming operations is expected to increase.

- The development of new stemming materials is expected to continue.

- The use of stemming operations in new and innovative applications is expected to grow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stemming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stemming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stemming Machine Operators play a crucial role in the manufacturing industry, operating and maintaining stemming machines that create explosives used in mining, quarrying, and construction projects.

1. Machine Operation and Maintenance

Operate stemming machines to fill drill holes with explosives, ensuring proper stemming density and compaction.

- Calibrate and adjust machine settings to optimize performance and explosive yields.

- Perform routine maintenance and inspections, including cleaning, lubrication, and minor repairs.

2. Quality Control

Inspect stemmed drill holes to ensure compliance with safety and quality standards.

- Monitor explosive levels and adjust machine parameters to maintain consistent stemming density.

- Conduct visual inspections to identify potential defects or inconsistencies in the stemming process.

3. Safety and Compliance

Uphold strict safety protocols and adhere to all applicable regulations related to the handling and use of explosives.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Maintain a clean and organized work area to minimize hazards and ensure a safe working environment.

4. Troubleshooting and Problem-Solving

Identify and resolve machine malfunctions, production issues, and other operational challenges.

- Use technical knowledge and troubleshooting skills to diagnose and rectify problems quickly.

- Coordinate with maintenance personnel to resolve complex issues or equipment breakdowns.

Interview Tips

Preparing thoroughly for your Stemming Machine Operator interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and industry standing. Research the specific role and its responsibilities to demonstrate your interest and understanding.

- Visit the company website and read industry news articles to gather information.

- Identify the key skills and experience required for the position and highlight them in your resume and cover letter.

2. Practice Your Answers

Prepare thoughtful and concise answers to common interview questions. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples.

- Anticipate questions about your technical skills, safety knowledge, and problem-solving abilities.

- Practice your answers out loud or with a friend to gain confidence and improve your delivery.

3. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive for your interview on time to show respect and professionalism.

- Choose appropriate business attire that is clean, pressed, and fits well.

- Allow ample time to travel to the interview location and avoid any potential delays.

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Prepare questions related to the company’s future plans, industry trends, or specific aspects of the role.

- Avoid asking generic or personal questions that may appear unprofessional.

5. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic attitude. Employers seek candidates who are passionate about their work and eager to join the team.

- Smile, make eye contact, and express your genuine interest in the opportunity.

- Highlight your strengths and qualifications while remaining humble and respectful.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Stemming Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!