Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Straightedge Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

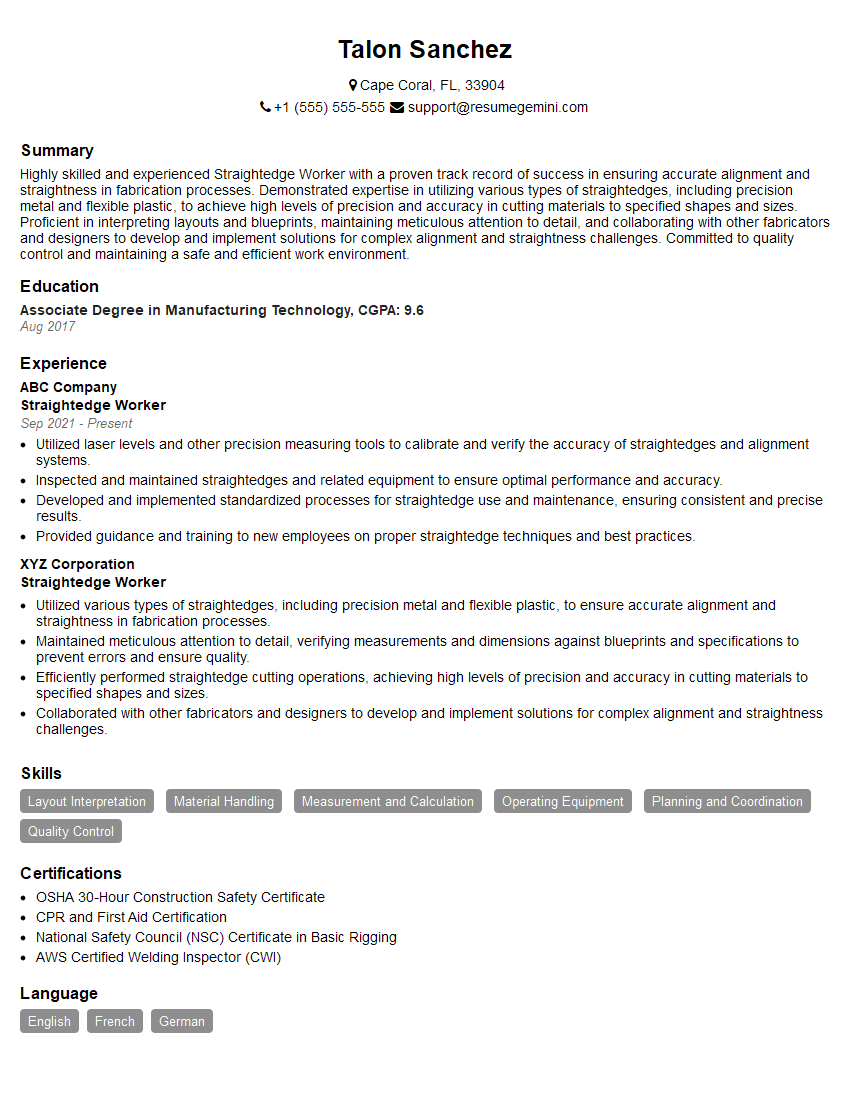

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Straightedge Worker

1. What is the purpose of using a straightedge in construction?

The purpose of using a straightedge in construction is to ensure straight and accurate lines and edges. It is a tool used to draw straight lines, check the flatness of surfaces, and align objects.

2. What are the different types of straightedges used in construction?

Wooden Straightedges

- Made from durable wood, such as maple or oak

- Lightweight and easy to handle

- Suitable for short runs and less demanding applications

Aluminum Straightedges

- Made from lightweight and durable aluminum

- Less prone to warping or bending than wooden straightedges

- Suitable for longer runs and more precise measurements

Magnetic Straightedges

- Embedded with magnets for secure attachment to ferrous surfaces

- Ideal for use on metal beams and other ferrous surfaces

- Provides accurate lines even on uneven surfaces

3. What are the key features to consider when selecting a straightedge for construction?

- Length and width: Determine the appropriate size based on the intended application

- Accuracy: Ensure the straightedge meets the required accuracy and tolerance levels

- Material: Choose a durable material that can withstand the rigors of construction

- Functionality: Consider special features such as magnetic attachment, scribing notches, or graduations

4. How do you ensure the accuracy of a straightedge?

- Calibrate the straightedge regularly using a known reference

- Check for any bends, warps, or damage before use

- Store the straightedge in a flat and protected location to maintain its accuracy

- Use a level or other measuring tool to verify the straightness of lines and surfaces

5. What are the common applications of straightedges in construction?

- Drawing straight lines for framing, drywall installation, and concrete work

- Checking the flatness of surfaces such as floors, walls, and countertops

- Aligning objects, such as pipes, beams, and fixtures

- Establishing level lines and slopes for drainage and landscaping

6. What safety precautions should be taken when using a straightedge?

- Wear appropriate safety gear, including gloves and safety glasses

- Inspect the straightedge before use and discard any damaged or defective tools

- Handle the straightedge with care to avoid cuts or injuries

- Secure the straightedge firmly to prevent it from slipping or moving

7. How do you maintain a straightedge?

- Clean the straightedge regularly with a damp cloth

- Lubricate moving parts, such as hinges, if necessary

- Store the straightedge in a dry and protected location when not in use

- Inspect the straightedge periodically for any signs of damage or wear

8. What are the advantages of using a straightedge over other measuring tools?

- Provides a straight and accurate reference line

- Can be used for longer measurements than rulers or tapes

- Is less prone to bending or warping than flexible measuring tools

- Can be used to check the flatness of surfaces

9. What are some advanced techniques for using a straightedge?

- Scribing: Using a sharp tool to mark a line onto a surface by following the straightedge

- Parallel marking: Creating multiple parallel lines by using a straightedge with graduations or pencil stops

- Angle measurements: Using a straightedge and a protractor to measure angles

- Contouring: Using a straightedge to create smooth curves and shapes

10. Can you describe a specific project where you used a straightedge and the challenges you encountered?

In a recent project involving the construction of a retaining wall, I utilized a straightedge to ensure the accuracy of the concrete formwork. The challenge arose due to the uneven terrain, which required precise measurements and careful alignment of the forms. By using a high-quality aluminum straightedge, I was able to establish straight lines and level surfaces, resulting in a successful and structurally sound wall.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Straightedge Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Straightedge Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Straightedge Worker is responsible for a variety of tasks related to the production and maintenance of straightedges, which are used in a variety of industries to ensure straightness and accuracy. Key job responsibilities include:

1. Straightedge Production

Producing straightedges according to specified dimensions and tolerances using specialized equipment and techniques.

- Setting up and operating machinery to cut, grind, and polish straightedges to precise specifications.

- Inspecting straightedges for accuracy and quality using precision measuring tools and techniques.

2. Straightedge Maintenance

Maintaining and repairing straightedges to ensure optimal performance and accuracy.

- Inspecting straightedges for wear and tear, and performing necessary repairs and adjustments.

- Calibrating and certifying straightedges to meet industry standards and customer specifications.

3. Quality Control

Ensuring the quality of straightedges produced by adhering to established quality standards and procedures.

- Conducting regular inspections and testing of straightedges to verify accuracy and compliance with specifications.

- Maintaining accurate records and documentation of all quality control activities.

4. Customer Support

Providing technical support and advice to customers on the use and maintenance of straightedges.

- Responding to customer inquiries and resolving technical issues related to straightedges.

- Providing training and guidance on proper straightedge handling and storage techniques.

Interview Tips

To ace an interview for a Straightedge Worker position, it is important to prepare thoroughly and showcase your knowledge and skills. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest advancements.

2. Practice Your Technical Skills

Review your knowledge of straightedge production, maintenance, and quality control techniques. Practice using precision measuring tools and demonstrate your ability to identify and resolve common straightedge issues.

- Set up a mock straightedge production or inspection station.

- Simulate troubleshooting scenarios and develop solutions.

3. Highlight Your Customer Service Skills

Emphasize your ability to provide excellent customer support. Describe your experience in handling technical inquiries and resolving customer issues effectively.

- Share examples of how you have successfully resolved customer complaints.

- Explain your approach to providing training and guidance to customers.

4. Quantify Your Accomplishments

Use specific numbers and metrics to quantify your accomplishments in previous roles. This will help the interviewer understand the impact of your contributions.

- Example: “Increased straightedge production efficiency by 15% by optimizing machine settings and implementing lean manufacturing techniques.”

- Example: “Reduced customer complaints by 20% by improving straightedge calibration and inspection procedures.”

Next Step:

Now that you’re armed with the knowledge of Straightedge Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Straightedge Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini