Are you gearing up for an interview for a Thermal Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Thermal Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

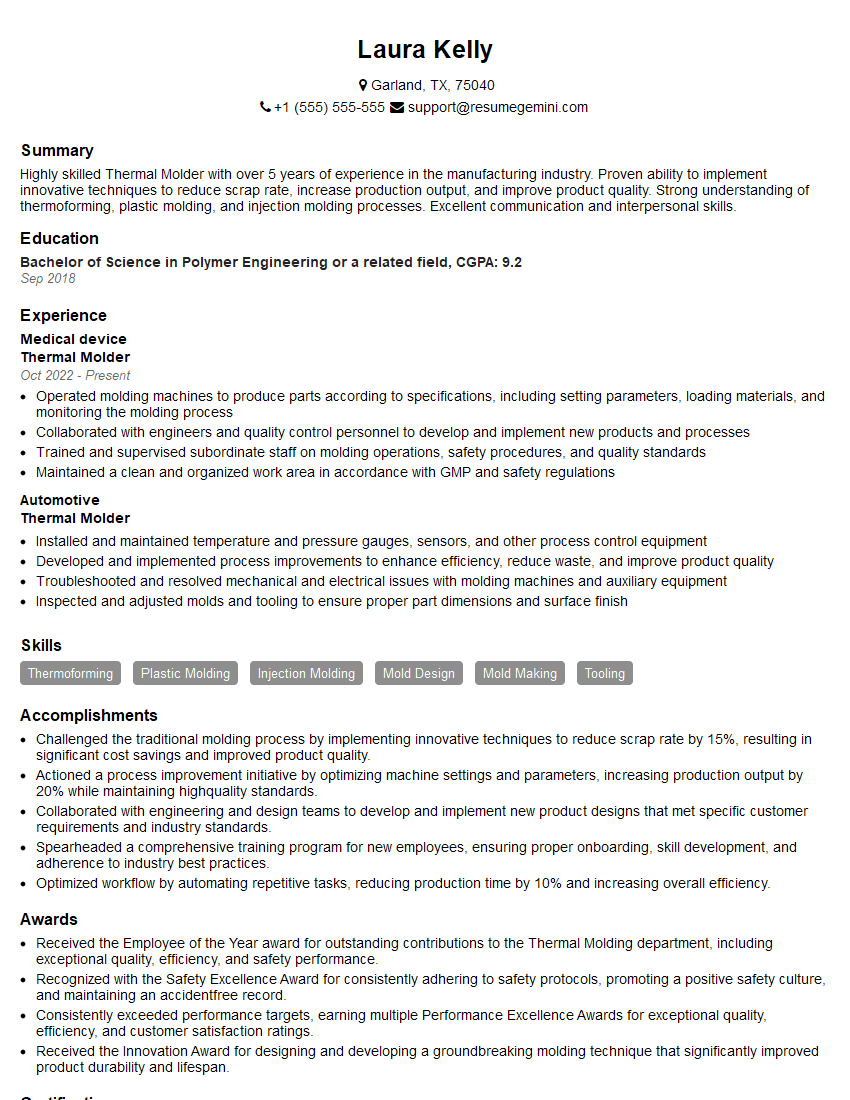

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thermal Molder

1. What are the different types of thermal molding processes?

There are three main types of thermal molding processes:

- Injection molding: In this process, molten plastic is injected into a mold cavity under high pressure. The mold is then cooled to solidify the plastic.

- Blow molding: In this process, molten plastic is extruded into a parison, which is then blown into a mold cavity using compressed air. The mold is then cooled to solidify the plastic.

- Extrusion molding: In this process, molten plastic is extruded through a die to form a continuous strip or shape. The extrudate is then cooled to solidify the plastic.

2. What are the key factors to consider when selecting a thermal molding process?

The key factors to consider when selecting a thermal molding process include:

Material Properties

- The material’s melt flow index (MFI)

- The material’s heat deflection temperature (HDT)

- The material’s glass transition temperature (Tg)

Part Design

- The part’s size and complexity

- The part’s wall thickness

- The part’s tolerances

Production Volume

- The number of parts required

- The production rate

3. What are the advantages and disadvantages of injection molding?

The advantages of injection molding include:

- High production rates

- Good dimensional accuracy

- Ability to produce complex parts

The disadvantages of injection molding include:

- High tooling costs

- Long cycle times

- Limited material selection

4. What are the advantages and disadvantages of blow molding?

The advantages of blow molding include:

- Low tooling costs

- Fast cycle times

- Wide material selection

The disadvantages of blow molding include:

- Limited part complexity

- Poor dimensional accuracy

- High scrap rates

5. What are the advantages and disadvantages of extrusion molding?

The advantages of extrusion molding include:

- Low tooling costs

- Fast cycle times

- Wide material selection

The disadvantages of extrusion molding include:

- Limited part complexity

- Poor dimensional accuracy

- High scrap rates

6. What is the difference between a positive mold and a negative mold?

In a positive mold, the mold cavity is the same shape as the finished part. In a negative mold, the mold cavity is the opposite shape of the finished part.

7. What is the role of a mold release agent?

A mold release agent is applied to the mold cavity to prevent the plastic from sticking to the mold. This helps to ensure that the finished part can be easily removed from the mold.

8. What are the different types of mold cooling systems?

The three main types of mold cooling systems are:

Water-cooled molds

Water-cooled molds use water to circulate through channels in the mold to remove heat from the plastic.

Air-cooled molds

Air-cooled molds use air to circulate over the mold to remove heat from the plastic.

Vacuum-cooled molds

Vacuum-cooled molds use a vacuum to draw air over the mold to remove heat from the plastic.

9. What are the different types of plastic materials used in thermal molding?

The most common types of plastic materials used in thermal molding include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- Polyvinyl chloride (PVC)

- Acrylonitrile butadiene styrene (ABS)

10. What are the career prospects for a thermal molder?

The career prospects for a thermal molder are good. The demand for thermal molded products is expected to continue to grow in the coming years. Thermal molders can work in a variety of industries, including automotive, consumer products, and medical.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thermal Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thermal Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Thermal Molder is responsible for operating and maintaining thermal molding machines to produce plastic parts and products.

1. Production

Operate thermal molding machines according to specifications.

- Set up and adjust machines.

- Monitor the molding process.

2. Quality Control

Inspect molded parts to ensure they meet quality standards.

- Identify and correct defects.

- Maintain quality records.

3. Machine Maintenance

Perform routine maintenance on thermal molding machines.

- Clean and lubricate machines.

- Troubleshoot and repair problems.

4. Material Handling

Receive and store raw materials.

- Load materials into machines.

- Dispose of waste materials.

Interview Tips

To ace the interview for a Thermal Molder position, candidates should follow some essential preparation tips:

1. Research the Company

Learn about the company’s products, services, and culture.

- Visit the company’s website.

- Read industry news and articles.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience, skills, and qualifications.

- Use the STAR method to answer behavioral questions.

- Highlight your relevant skills and experience.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions demonstrates your interest and engagement.

- Ask about the company’s growth plans.

- Inquire about training and development opportunities.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately and arrive punctually.

- Wear business casual attire.

- Arrive 15 minutes early for the interview.

5. Be Enthusiastic and Confident

Show your passion for the role and your confidence in your abilities.

- Maintain eye contact and speak clearly.

- Use positive body language.

Example Outline

To illustrate, when asked about your experience operating thermal molding machines, you could use the STAR method as follows:

- Situation: Describe a specific situation where you operated a thermal molding machine.

- Task: Explain the task you were responsible for completing.

- Action: Describe the actions you took to complete the task.

- Result: Quantify the results of your actions and highlight your contribution.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thermal Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!