Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tieing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tieing Machine Operator so you can tailor your answers to impress potential employers.

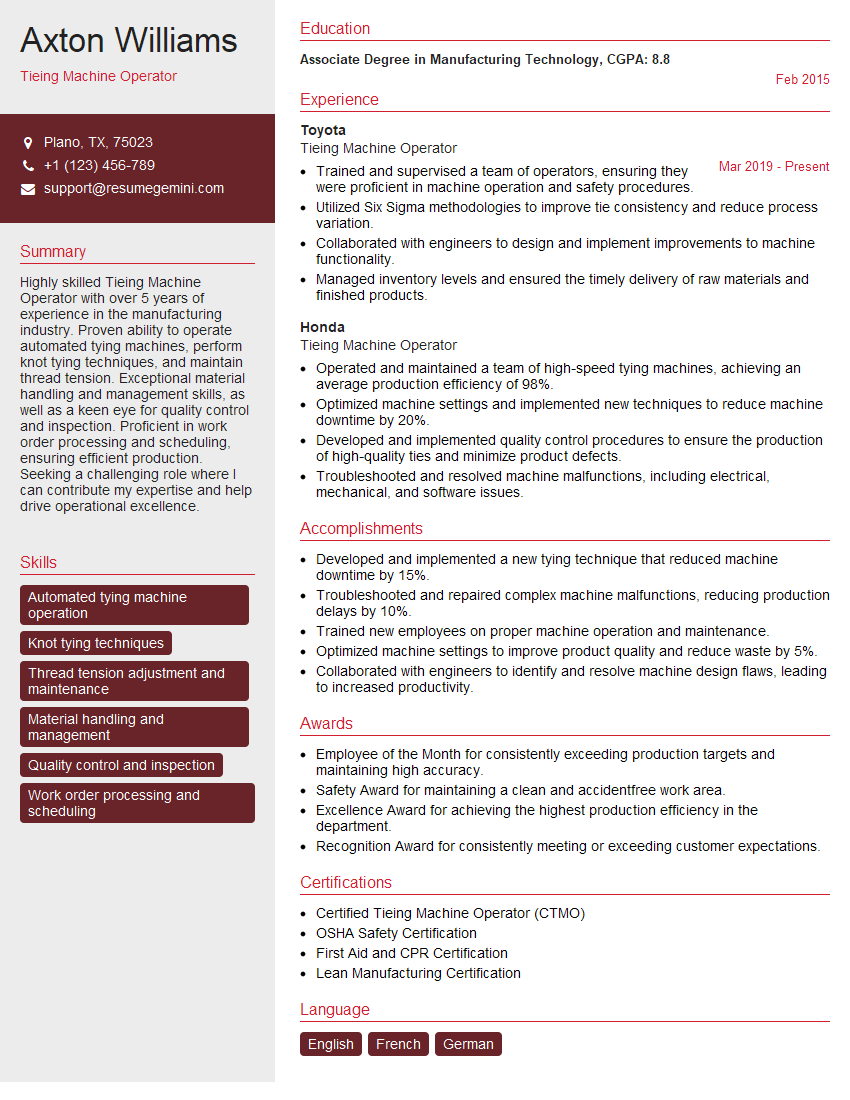

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tieing Machine Operator

1. How do you ensure the accuracy of the bundle weights when operating a tying machine?

- Regularly calibrate the weighing system using certified weights to maintain precision.

- Inspect the products for proper placement and orientation to prevent incorrect weight readings.

2. Describe the different types of knots used with a tying machine and when each is appropriate.

Square Knot

- Most common and widely used knot.

- Reliable and secure for general packaging applications.

Overhand Knot

- Used when the bundle is not subject to heavy lifting or stress.

- Simple and quick to tie.

3. How do you troubleshoot a tying machine that is not tying knots correctly?

Begin by examining the twine and ensuring it is of the correct type and tension. Then check for any damage or obstruction in the knotting mechanism. If the issue persists, inspect the tension adjustment and ensure it is within the recommended range. Finally, verify the machine settings and make any necessary adjustments to optimize knot quality.

4. What maintenance procedures are essential for keeping a tying machine in good working condition?

- Regularly clean and lubricate all moving parts to prevent wear and corrosion.

- Inspect and replace worn or damaged components, such as knotting blades and twine guides.

- Check and adjust tension settings to ensure optimal knotting performance.

5. How do you calculate the optimal length of twine needed for each bundle?

To determine the required twine length, measure the circumference of the bundle and multiply it by a factor based on the desired number of wraps and knot type. The factor for a square knot is typically 1.5 to 2.0, and for an overhand knot, it is around 1.2 to 1.5.

6. What safety precautions should be followed when operating a tying machine?

- Wear appropriate personal protective equipment, including gloves and safety glasses.

- Keep hands and loose clothing away from the knotting mechanism during operation.

- Never attempt to clear jams or make adjustments while the machine is running.

7. How do you handle situations where the tying machine encounters products of varying sizes and shapes?

- Adjust the machine settings, such as twine tension and knotting force, to accommodate different product dimensions.

- Use different twine sizes or types to ensure secure knots for specific product characteristics.

8. What factors affect the speed and efficiency of a tying machine?

- Type and condition of the twine.

- Settings and adjustments of the machine.

- Nature and size of the products being tied.

9. How do you maintain a consistent knot quality throughout a production run?

- Monitor the machine performance and make adjustments as needed to optimize knot strength and appearance.

- Regularly inspect and maintain the machine to prevent any deterioration that could impact knot quality.

10. What are some troubleshooting tips for common tying machine issues, such as broken twine or missed knots?

- For broken twine, inspect the twine spool and tension settings to ensure proper tension.

- For missed knots, check the knotting mechanism for any damage or obstruction and ensure the twine is properly threaded into the machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tieing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tieing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tieing Machine Operators are responsible for operating and maintaining tying machines used in the packaging industry. They are responsible for setting up, operating, and adjusting the machine to tie various types of materials, such as bags, boxes, and bundles. They also inspect the finished product to ensure it meets quality standards.

1. Set Up and Operate Tying Machine

Tieing Machine Operators set up and operate tying machines according to established procedures.

- Position materials to be tied on the machine.

- Adjust machine settings, such as tension, speed, and knot type.

- Start the machine and monitor its operation.

2. Monitor Finished Product

Tieing Machine Operators monitor the finished product to ensure it meets quality standards. They inspect the product for defects, such as loose knots or uneven spacing.

- Visually inspect the tied product for defects.

- Use measuring tools to ensure the product meets specifications.

- Reject defective products and report any problems to the supervisor.

3. Maintain Tying Machine

Tieing Machine Operators maintain tying machines to ensure they are in good working condition. They perform routine maintenance tasks, such as cleaning, lubricating, and adjusting the machine.

- Clean the machine regularly to remove dirt and debris.

- Lubricate moving parts to prevent wear and tear.

- Adjust the machine to ensure it is operating properly.

4. Troubleshoot and Repair Problems

Tieing Machine Operators troubleshoot and repair problems that occur with the machine. They identify the source of the problem and take steps to resolve it.

- Identify the source of the problem.

- Make necessary repairs or adjustments.

- Test the machine to ensure it is working properly.

Interview Tips

To ace the interview for a Tieing Machine Operator position, it is important to prepare thoroughly. Here are some tips to help you prepare for the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company website to learn about their history, mission, and values.

- Read reviews of the company on Glassdoor to get an idea of the company culture and work environment.

- Look up the specific job description for the position you are applying for to understand the requirements of the job.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked in an interview for a Tieing Machine Operator position. It is helpful to practice answering these questions in advance so that you can feel more confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with tying machines?

- How do you handle troubleshooting problems with machinery?

3. Be Prepared to Talk About Your Experience

In the interview, you will be asked about your experience working with tying machines. Be prepared to talk about your specific tasks and responsibilities in your previous roles.

- Describe the types of tying machines you have operated.

- Discuss the specific tasks you performed as a Tieing Machine Operator.

- Highlight any achievements or successes you have had in your previous roles.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This shows that you are interested in the opportunity and that you are taking the interview seriously.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the Tieing Machine Operator position.

- Ask about the company’s plans for the future.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tieing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!