Feeling lost in a sea of interview questions? Landed that dream interview for Tile Presser but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tile Presser interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

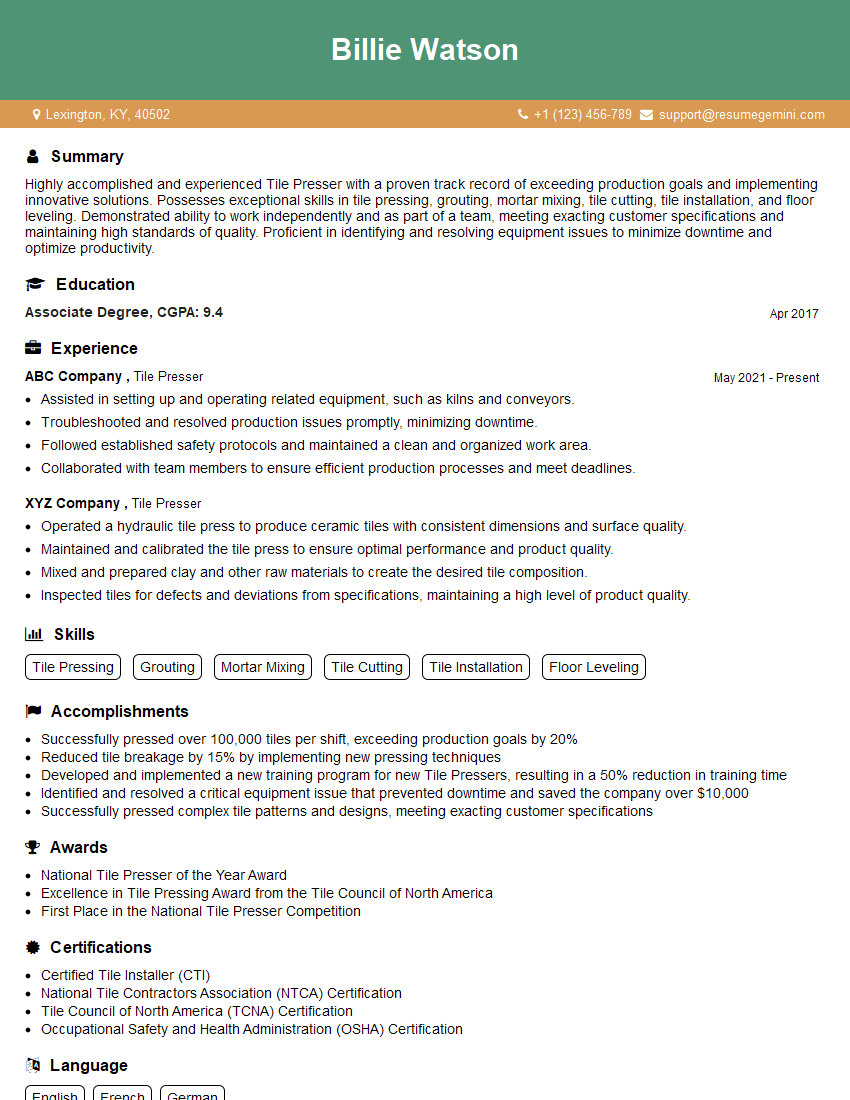

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tile Presser

1. What are the different types of tile presses and their uses?

- Extrusion press: This type of press is used to create long, continuous pieces of tile by forcing clay through a die. Extrusion presses are typically used for producing floor and wall tiles.

- Dry press: This type of press uses a plunger to compact dry clay powder into a tile shape. Dry presses are typically used for producing wall and roof tiles.

- Plastic press: This type of press uses a combination of heat and pressure to mold clay into a tile shape. Plastic presses are typically used for producing floor and wall tiles.

2. What are the different factors that affect the quality of a tile?

- The type of clay: Different types of clay have different properties that can affect the quality of a tile. For example, some clays are more durable than others, while others are more resistant to moisture.

- The firing temperature: The temperature at which a tile is fired can also affect its quality. Tiles that are fired at a higher temperature are typically harder and more durable than tiles that are fired at a lower temperature.

- The glazing: The glaze that is applied to a tile can also affect its quality. Glazes can help to protect the tile from moisture and wear, and they can also add color and decoration.

3. What are the different types of tile defects and how do you fix them?

- Cracks: Cracks can be caused by a variety of factors, including improper drying, firing, or handling. Cracks can be repaired by filling them with a tile repair compound.

- Chips: Chips can be caused by impact or abrasion. Chips can be repaired by filling them with a tile repair compound.

- Scratches: Scratches can be caused by abrasion or improper cleaning. Scratches can be repaired by polishing the tile with a tile polishing compound.

4. What are the different safety precautions that should be taken when operating a tile press?

- Wear appropriate safety gear: This includes safety glasses, gloves, and a hard hat.

- Be aware of your surroundings: Make sure that you have enough space to operate the press safely and that there are no obstacles in your way.

- Follow the manufacturer’s instructions: Each tile press is different, so it is important to follow the manufacturer’s instructions for safe operation.

5. What are the different maintenance tasks that should be performed on a tile press?

- Clean the press regularly: This will help to prevent the build-up of clay and other debris.

- Lubricate the moving parts: This will help to keep the press running smoothly.

- Inspect the press for wear and tear: This will help to identify any potential problems before they become major issues.

6. What are the different troubleshooting techniques that can be used to fix a tile press?

- Check the power supply: Make sure that the press is plugged in and that the power switch is turned on.

- Check the hydraulic fluid level: If the fluid level is low, add more fluid until it reaches the proper level.

- Check the pressure relief valve: If the pressure relief valve is stuck open, it will need to be replaced.

7. What are the different types of tiles that can be produced using a tile press?

- Floor tiles: These tiles are typically made from durable materials like porcelain or ceramic and are designed to withstand heavy foot traffic.

- Wall tiles: These tiles are typically made from lighter materials like ceramic or glass and are designed to be used on walls.

- Roof tiles: These tiles are typically made from durable materials like concrete or clay and are designed to protect a roof from the elements.

8. What are the different factors that affect the production rate of a tile press?

- The type of press: Different types of presses have different production rates.

- The size of the tiles: Larger tiles take longer to produce than smaller tiles.

- The thickness of the tiles: Thicker tiles take longer to produce than thinner tiles.

9. What are the different ways to improve the efficiency of a tile press?

- Use the proper dies: The dies that are used to shape the tiles can have a significant impact on the production rate.

- Use the proper lubricants: Lubricants can help to reduce friction and improve the flow of clay through the press.

- Keep the press clean: A clean press will run more efficiently than a dirty press.

10. What are the different types of tile press manufacturers?

- Italian manufacturers: Italian manufacturers are known for producing high-quality tile presses.

- Spanish manufacturers: Spanish manufacturers are known for producing affordable tile presses.

- Chinese manufacturers: Chinese manufacturers are known for producing a wide range of tile presses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tile Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tile Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tile pressers play a crucial role in the construction industry by operating tile pressing machines to produce ceramic or concrete tiles. Here are their key job responsibilities:

1. Machine Operation

Operate tile pressing machines to mold and shape clay, concrete, or other materials into tiles.

- Adjust machine settings to ensure proper tile dimensions and thickness.

- Monitor the machine during operation to detect and correct any malfunctions.

2. Quality Control

Inspect tiles for defects such as chips, cracks, or uneven surfaces.

- Sort tiles based on quality standards and place them in designated areas.

- Calibrate and maintain measuring equipment to ensure accuracy in tile dimensions.

3. Maintenance and Repair

Perform routine maintenance on tile pressing machines to prevent breakdowns and ensure efficient operation.

- Clean and lubricate machine components.

- Identify and replace worn or damaged parts.

4. Production Management

Manage the production process to meet deadlines and production targets.

- Coordinate with other team members to ensure a smooth flow of materials and products.

- Maintain inventory records and report production data.

Interview Tips

Preparing thoroughly for a tile presser interview can significantly increase your chances of making a positive impression and landing the job. Here are some tips to help you:

1. Research the Company and Role

Learn about the company’s history, values, and current projects. Understand the specific responsibilities of the tile presser role and how it aligns with your skills and experience.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay informed about tile pressing trends.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating and maintaining tile pressing machines. Showcase your attention to detail and ability to identify and correct quality issues.

- Quantify your accomplishments to demonstrate your impact on production efficiency or quality.

- Provide specific examples of how you have solved problems or improved processes in a tile pressing environment.

3. Be Enthusiastic and Professional

Convey your passion for tile pressing and your commitment to delivering high-quality products. Dress professionally and arrive on time for your interview.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Maintain eye contact and speak clearly and confidently during the interview.

4. Ask Thoughtful Questions

Asking well-informed questions shows that you are engaged and interested in the role. Prepare a few questions about the company’s production processes, quality standards, or future projects.

- Avoid asking generic questions that can be easily found on the company’s website.

- Use your questions to demonstrate your knowledge of the industry and your commitment to continuous learning.

Next Step:

Now that you’re armed with the knowledge of Tile Presser interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tile Presser positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini