Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tin Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

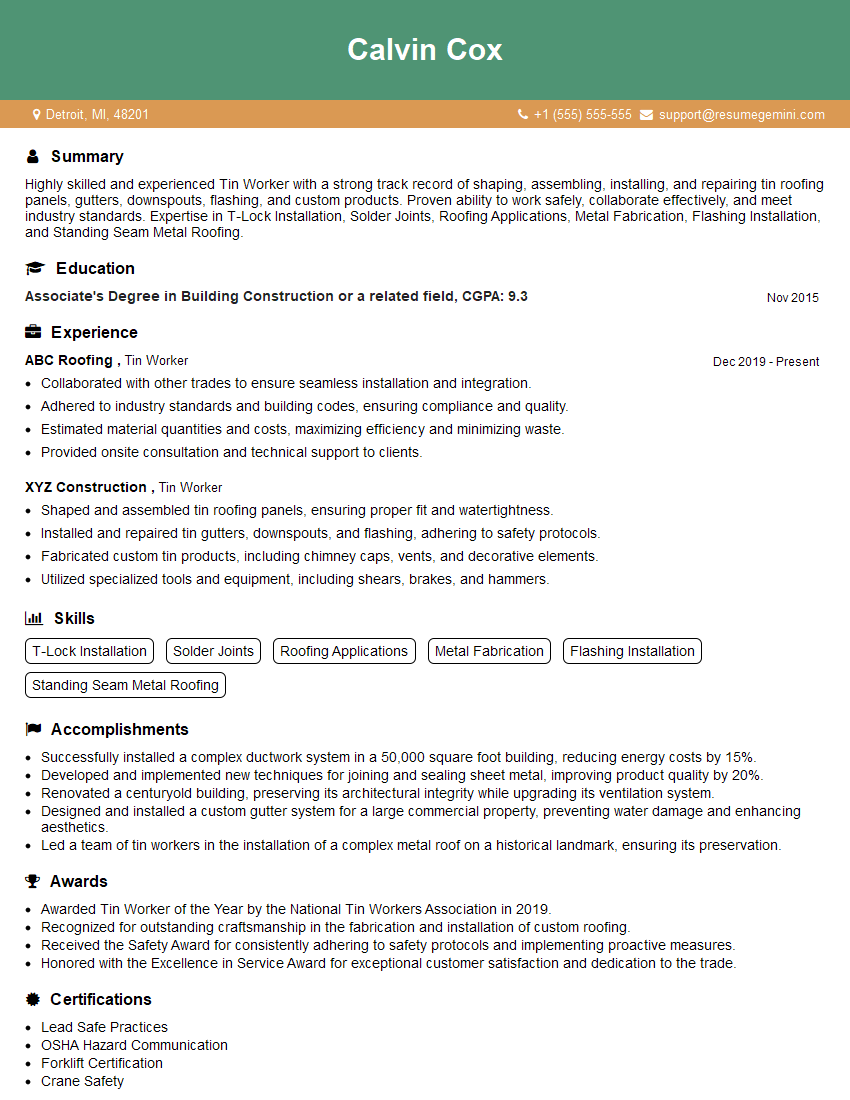

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tin Worker

1. How do you ensure that the cut tin pieces are accurate and precise?

To ensure accuracy and precision in cut tin pieces, I employ the following techniques:

- Measuring Tools: I use precise measuring tools such as rulers, squares, and calipers to accurately mark and measure the dimensions of the tin sheets before cutting.

- Sharp Cutters: I maintain sharp cutting tools, including shears and snips, to ensure clean and precise cuts.

- Layout Techniques: I use layout techniques such as scribing, tracing, and marking to transfer measurements and patterns onto the tin sheet.

- Visual Inspection: I carefully inspect each cut piece to ensure it meets the specified dimensions and shape.

2. Describe the process you use to form and shape tin sheets.

To form and shape tin sheets, I follow a systematic process that includes:

Bending

- Hand Bending: I use hand tools such as pliers and bending brakes to manually bend tin sheets into desired shapes.

- Machine Bending: For more precise and complex bends, I utilize bending machines that apply controlled pressure and angle.

Rolling

- Hand Rolling: I use a rolling mill or hand-held rolling tools to create cylindrical or curved shapes.

- Machine Rolling: For large-scale or heavy-duty rolling, I operate rolling machines that provide consistent and accurate results.

3. How do you handle and store tin sheets to prevent damage and contamination?

To preserve the integrity of tin sheets and prevent damage or contamination, I adhere to the following practices:

- Proper Storage: I store tin sheets in a dry and well-ventilated area, protected from moisture, heat, and direct sunlight.

- Moisture Protection: I use moisture-resistant packaging materials and place silica gel packets inside storage containers to absorb moisture.

- Protective Layer: I apply a thin layer of lubricant or protective coating to the surface of the sheets to prevent oxidation and corrosion.

- Handling Precautions: I wear gloves and use proper lifting techniques to avoid bending or scratching the sheets during handling.

4. Describe your experience in soldering and welding tin sheets.

I possess proficient skills in soldering and welding tin sheets, employing the following techniques:

Soldering

- Flux Application: I apply flux to the surfaces to be joined, promoting solder adhesion.

- Solder Selection: I choose the appropriate solder alloy based on the type of tin and the desired joint strength.

- Heating and Joining: I use a soldering iron to heat and melt the solder, carefully joining the tin sheets.

Welding

- TIG Welding: I utilize TIG welding (tungsten inert gas) for precise and high-quality welds on thin tin sheets.

- MIG Welding: I employ MIG welding (metal inert gas) for efficient and faster welding applications.

5. How do you ensure the quality of your finished tin products?

To guarantee the quality of my finished tin products, I implement the following measures:

- Visual Inspection: I conduct thorough visual inspections to check for any defects, such as scratches, dents, or uneven soldering.

- Dimensional Accuracy: I use measuring tools to verify that the product conforms to the specified dimensions and tolerances.

- Functional Testing: For products with functional requirements, I perform tests to ensure they operate as intended.

- Customer Feedback: I gather feedback from customers to identify areas for improvement and maintain high product quality.

6. Describe your understanding of the different types of tin used in sheet metal work.

I am familiar with the various types of tin used in sheet metal work, including:

- Pure Tin: Pure tin is highly malleable and ductile, making it ideal for decorative and ornamental applications.

- Tin-Coated Steel: This type consists of a thin layer of tin electroplated onto steel, providing corrosion resistance and strength.

- Terne-Coated Steel: Terne-coated steel is similar to tin-coated steel but uses a lead-tin alloy instead of pure tin, offering enhanced corrosion resistance.

- Tin-Zinc Alloy: Tin-zinc alloy sheets combine the corrosion resistance of tin with the strength and formability of zinc.

7. How do you maintain and troubleshoot equipment used in tin sheet metal work?

To maintain and troubleshoot equipment used in tin sheet metal work, I follow these steps:

- Regular Maintenance: I perform scheduled maintenance tasks such as lubrication, cleaning, and calibration to ensure optimal performance.

- Troubleshooting: When equipment malfunctions, I systematically identify the issue by checking power supply, electrical connections, and mechanical components.

- Repair and Adjustment: I possess the skills to repair minor issues and make adjustments to restore equipment functionality.

- Collaboration with Experts: For complex or major repairs, I consult with experienced technicians or manufacturers for assistance.

8. Describe your experience in working with blueprints and technical drawings.

I am proficient in interpreting blueprints and technical drawings, which is essential for accurate fabrication of tin sheet metal products. My experience includes:

- Blueprint Reading: I can interpret complex blueprints, understanding symbols, dimensions, and specifications.

- Drawing Interpretation: I accurately translate technical drawings into detailed work instructions for production.

- Dimensional Analysis: I analyze drawings to determine the required dimensions and tolerances of the finished product.

9. Explain how you ensure workplace safety when working with tin sheets.

Ensuring workplace safety is paramount. I adhere to the following practices:

- Personal Protective Equipment: I wear appropriate safety gear, including gloves, safety glasses, and earplugs, when operating machinery.

- Sharp Object Handling: I handle sharp tools, such as shears and knives, with caution and proper techniques.

- Ventilation: I ensure adequate ventilation in the workspace to prevent inhalation of fumes or dust.

- Machine Safety: I follow established safety protocols for operating machinery, including lockout/tagout procedures before maintenance.

10. Describe your approach to learning new techniques and adapting to changing industry standards.

I am committed to continuous learning and adapting to evolving industry standards. My approach includes:

- Technical Journals and Publications: I stay updated with industry trends by reading technical journals and publications.

- Training and Workshops: I attend workshops and training programs to enhance my skills and knowledge.

- Collaboration with Colleagues: I engage in knowledge sharing and collaboration with colleagues to learn new techniques and innovative approaches.

- Open-mindedness: I embrace new technologies and methodologies, adapting my practices accordingly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tin Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tin Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tin Workers are responsible for shaping, forming, and installing sheet metal products in a variety of industrial and commercial settings. They are skilled craftsmen who use specialized tools and techniques to create complex and durable products that meet exact specifications.

1. Fabricate and Install Sheet Metal Products

Tin Workers fabricate and install sheet metal products for a variety of applications, including roofing, siding, gutters, downspouts, and flashing. They use a variety of tools and techniques to cut, bend, and shape sheet metal into the desired shape and size.

- Cut sheet metal using shears, nibblers, or plasma cutters.

- Bend sheet metal using brakes, rolls, or hammers.

- Shape sheet metal using dies, punches, or other forming tools.

- Install sheet metal products using screws, bolts, nails, or adhesives.

2. Inspect and Repair Sheet Metal Products

Tin Workers inspect and repair sheet metal products to ensure that they are in good condition and functioning properly. They look for signs of damage, such as cracks, holes, or rust, and make repairs as needed.

- Inspect sheet metal products for damage.

- Repair sheet metal products using soldering, welding, or other techniques.

- Replace sheet metal products that are damaged beyond repair.

3. Maintain Equipment

Tin Workers maintain their tools and equipment to ensure that they are in good working condition. They clean and lubricate tools, and make repairs as needed.

- Clean and lubricate tools and equipment.

- Make repairs to tools and equipment.

- Order new tools and equipment as needed.

4. Follow Safety Procedures

Tin Workers follow safety procedures to protect themselves and others from injuries. They wear appropriate safety gear, such as gloves, safety glasses, and hard hats, and use tools and equipment safely.

- Wear appropriate safety gear.

- Use tools and equipment safely.

- Follow safety procedures.

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and what they are looking for in a candidate.

- Visit the company’s website.

- Read the job description.

- Talk to people in your network who work for the company.

2. Practice Your Answers

Once you have a good understanding of the company and the position, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Use the STAR method to answer questions.

- Tell a story that highlights your skills and experience.

- Be specific and provide examples.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Choose clothes that are clean, pressed, and fit well.

- Avoid wearing revealing or distracting clothing.

- Make sure your shoes are clean and polished.

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. This shows that you are respectful of the interviewer’s time and that you are serious about the job.

- Plan your route in advance.

- Leave early to give yourself plenty of time.

- If you are running late, call the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tin Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.