Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tire Groover position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

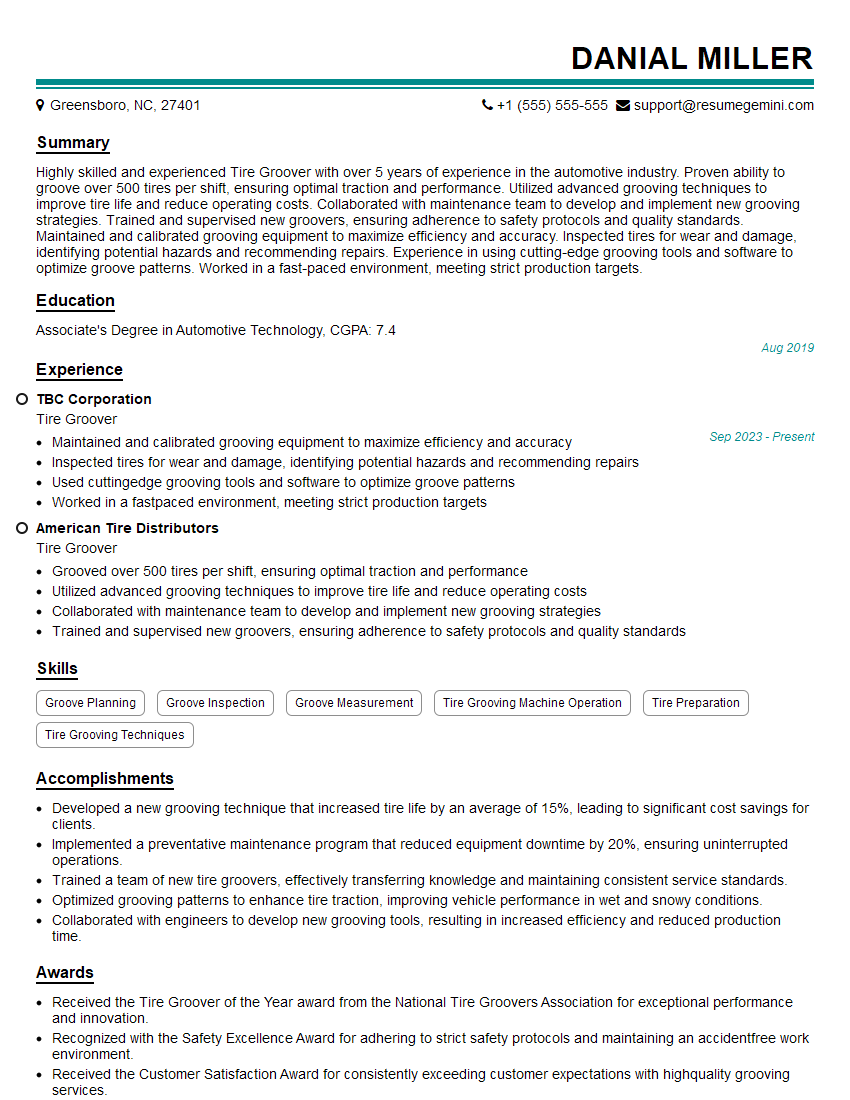

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Groover

1. What are the different types of tire grooves and their purposes?

There are several types of tire grooves, each designed for specific purposes:

- Circumferential grooves: These grooves run around the tire’s circumference and are primarily responsible for water evacuation, preventing hydroplaning.

- Lateral grooves: These grooves run perpendicular to the circumferential grooves and help channel water away from the center of the tire, aiding in traction.

- Diagonal grooves: These grooves are angled and help improve traction on slippery surfaces by creating biting edges.

- Sipes: These are small, thin grooves cut into the tire’s tread blocks and enhance traction in winter conditions by increasing the tire’s flexibility.

2. How do you determine the optimal groove depth for a specific tire and application?

Factors to consider:

- Tire type: Different tire designs require specific groove depths to perform optimally.

- Intended use: Tires used for high-performance driving or off-road conditions may require deeper grooves for enhanced traction.

- Road conditions: Deeper grooves are more suitable for wet or slippery roads, while shallower grooves may be preferred for dry conditions.

Measurement and evaluation:

- Tread depth gauge: Use a specialized tool to measure the remaining tread depth accurately.

- Legal requirements: Adhere to minimum tread depth regulations set by authorities.

- Manufacturer’s recommendations: Consult the tire manufacturer’s specifications for optimal groove depth for the specific tire model.

3. Describe the process of tire grooving and its benefits.

Tire grooving involves cutting additional grooves into the tire’s tread pattern to enhance traction and performance:

- Improved water evacuation: Deeper grooves allow for better water channeling, reducing the risk of hydroplaning.

- Enhanced traction: Additional grooves create more biting edges, improving grip on slippery surfaces.

- Extended tire life: Grooving can extend the tire’s lifespan by providing additional tread depth.

- Reduced noise: Grooves can help reduce tire noise by dispersing air more effectively.

4. What are the limitations and potential risks associated with tire grooving?

While tire grooving offers benefits, there are also some limitations and potential risks to consider:

- Reduced tire strength: Grooving can weaken the tire’s structure, potentially reducing its load-bearing capacity.

- Voiding warranty: Some tire manufacturers may void the warranty if the tire is grooved.

- Inapplicability for certain tires: Not all tires are suitable for grooving, especially tires with shallow tread patterns or tires designed for specific applications.

5. Explain the different types of tire grooving equipment and their applications.

- Manual tire groovers: Handheld tools used for small-scale grooving operations, often used for off-road tires.

- Semi-automatic tire groovers: Benchtop machines that provide more precision and efficiency than manual groovers, suitable for larger-scale operations.

- Fully automatic tire groovers: Automated systems that offer high-volume grooving with consistent results, typically used in commercial tire shops.

6. Describe the safety precautions and best practices for tire grooving.

- Inspect the tire: Check the tire for any damage or defects before grooving.

- Wear appropriate safety gear: Eye protection, hearing protection, and gloves are essential.

- Secure the tire: Ensure the tire is securely mounted on a stable surface.

- Follow manufacturer’s instructions: Adhere to the specified operating procedures and safety guidelines provided by the equipment manufacturer.

7. How do you maintain and calibrate tire grooving equipment?

- Regular cleaning: Remove dirt and debris from the equipment periodically.

- Blade inspection: Check cutter blades for wear or damage and replace them if necessary.

- Calibration: Ensure the equipment is correctly calibrated to achieve the desired groove depth and spacing.

- Lubrication: Lubricate moving parts as per the manufacturer’s instructions to ensure smooth operation.

8. How do you troubleshoot common issues encountered in tire grooving?

- Uneven groove depth: Adjust the equipment settings or cutter blades to ensure consistent grooving.

- Skipped grooves: Inspect the cutter blades for damage and replace them if necessary.

- Excessive noise or vibration: Check for loose parts, damaged bearings, or improper lubrication.

- Tire damage: If the tire is damaged during grooving, discontinue the process and seek professional assistance.

9. What are the different techniques used to improve the bonding between tire grooves and the road surface?

- Siping: Cutting small, thin grooves into the tire’s tread blocks to increase flexibility and traction.

- Surface roughening: Creating a roughened surface on the tread to enhance grip.

- Chemical treatment: Applying chemicals to the tire’s surface to improve bonding with the road surface.

10. How do you evaluate the effectiveness of tire grooving based on performance metrics?

- Traction testing: Measure the tire’s grip on different surfaces and conditions.

- Hydroplaning resistance: Assess the tire’s ability to resist water buildup and maintain traction on wet surfaces.

- Treadwear analysis: Monitor the tire’s tread depth and wear patterns to evaluate the effectiveness of grooving in extending tire life.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Groover.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Groover‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Groovers are responsible for operating and maintaining tire grooving equipment to create grooves in tires. These grooves improve traction, especially in wet and icy conditions. Day-to-day responsibilities include:1. Equipment Operation and Maintenance

- Operate tire grooving machines to cut precise grooves into tires.

- Set up and calibrate equipment, ensuring optimal performance and accuracy.

- Perform routine maintenance on equipment, including cleaning, lubrication, and minor repairs.

2. Tire Inspection and Selection

- Inspect tires to determine groove patterns and depth requirements.

- Select appropriate grooving tools and adjust equipment accordingly.

- Identify damaged or defective tires that require further attention or replacement.

3. Grooving Techniques and Quality Control

- Apply specialized techniques to create grooves that meet industry standards and customer specifications.

- Monitor grooving process to ensure consistent results and prevent over- or under-cutting.

- Inspect finished tires to verify groove depth, pattern, and overall quality.

4. Customer Service and Communication

- Provide excellent customer service by explaining grooving procedures and answering inquiries.

- Communicate with customers to determine specific groove requirements and provide updates on the progress of the work.

- Maintain open lines of communication to address any concerns or issues promptly.

Interview Tips

To prepare effectively for a Tire Groover interview, consider these tips:1. Research the Company and Industry

- Familiarize yourself with the company’s values, history, and products.

- Stay up-to-date on the latest industry trends and advancements in tire grooving.

2. Highlight Relevant Skills and Experience

- Emphasize your proficiency in operating and maintaining tire grooving equipment.

- Provide examples of your attention to detail and commitment to quality control.

- Share experiences in customer service and effective communication.

3. Prepare Examples Using the STAR Method

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your work experiences.

- Describe a situation where you successfully resolved a technical issue with a tire grooving machine.

- Explain a time when you went above and beyond to meet customer expectations.

4. Practice Answering Common Interview Questions

- Anticipate questions such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

- Prepare concise and well-structured responses that highlight your qualifications.

- Consider practicing with a mentor or friend to gain feedback.

5. Dress Professionally and Be Punctual

- Pay attention to your appearance and ensure you dress appropriately for the interview setting.

- Arrive on time to demonstrate your punctuality and respect for the interviewer’s time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tire Groover, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tire Groover positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.