Feeling lost in a sea of interview questions? Landed that dream interview for Tire Installer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tire Installer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

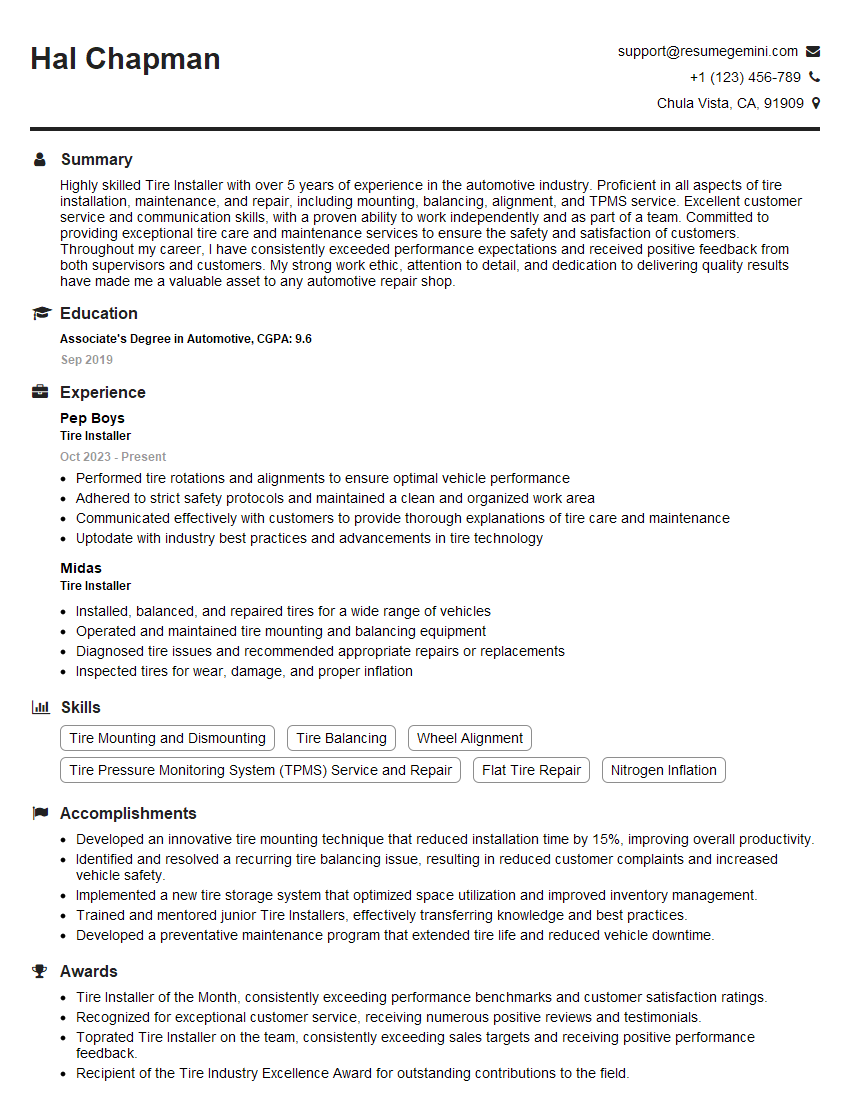

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Installer

1. What are the different types of tires available for vehicles?

There are various types of tires available for vehicles, each designed for specific purposes and vehicle types. Some common types include:

- Passenger car tires: Designed for everyday use on passenger vehicles, providing a balance of grip, comfort, and durability.

- Light truck and SUV tires: Suitable for light trucks and SUVs, offering enhanced durability and load-carrying capacity.

- Performance tires: Engineered for high-performance vehicles, providing exceptional handling and grip on dry and wet surfaces.

- All-season tires: Versatile tires designed to perform well in various conditions, including wet, dry, and light snow.

- Winter tires: Specialized tires designed for cold temperatures and snowy conditions, offering improved traction and safety.

- Run-flat tires: Tires that allow vehicles to continue driving for a limited distance even after a puncture, providing added peace of mind.

2. How do you ensure proper bead seating during tire installation?

Checking the bead and surface

- Inspect the tire bead for any damage or debris that may prevent proper seating.

- Clean the bead area of the wheel to remove any rust or dirt that could interfere with the seal.

Applying lubricant

- Apply a thin layer of tire mounting lubricant or soapy water to the bead area of the tire to help it slide onto the wheel.

- Avoid using excessive lubricant, as it can make the tire slippery and difficult to handle.

Mounting the tire

- Carefully place the tire onto the wheel, aligning the bead with the wheel’s bead seat.

- Use tire levers or a mounting machine to pry the bead over the wheel’s edge, starting at the valve stem.

Inflating the tire

- Partially inflate the tire to help the bead seat properly.

- Check the tire pressure and adjust it to the manufacturer’s specifications.

3. What are the key considerations when balancing tires?

- Weight distribution: Distribute weight evenly around the circumference of the tire to eliminate vibrations.

- Wheel static imbalance: Adjust weights on the wheel opposite the heavy spot to counterbalance the weight of the valve stem and tire.

- Wheel dynamic imbalance: Adjust weights on the wheel to minimize both static and dynamic imbalances, considering the combined weight of the tire and wheel.

- Road force variation: Address any irregularities in the tire’s shape or construction by using a road force balancer to identify and correct areas with excessive force variation.

4. How do you identify and repair a slow leak in a tire?

- Locating the leak: Use a soapy water solution to spray around the tire, looking for bubbles that indicate the source of the leak.

- Marking the leak: Once the leak is found, mark its location on the tire sidewall with chalk or a marker.

- Preparing the tire: Remove the wheel from the vehicle and dismount the tire from the wheel.

- Plugging the leak: Use a tire plug or patch kit to seal the hole or puncture causing the leak.

- Rebalancing the tire: Rebalance the tire to ensure proper weight distribution after the repair.

5. Describe the process of rotating tires to ensure even wear.

- Front to back: Move the front tires to the rear, and vice versa.

- Crossover: Swap the front left tire with the rear right tire, and vice versa.

- Even wear: This rotation pattern helps distribute wear evenly across all four tires, extending their lifespan and improving vehicle performance.

6. What safety precautions should be taken when working with tires?

- Proper clothing and equipment: Wear gloves, safety glasses, and appropriate footwear to protect against cuts and injuries.

- Tire inflation safety: Use a tire inflation cage or restraint to prevent the tire from exploding if it bursts.

- Lifting and handling: Use proper lifting equipment and techniques to avoid injuries when handling heavy tires.

- Tire disposal: Dispose of old or damaged tires responsibly at designated recycling facilities.

7. How do you inspect brakes during a tire service?

- Visual inspection: Check for any obvious signs of wear, damage, or leaks on the brake pads, rotors, and calipers.

- Pad thickness: Measure the thickness of the brake pads to ensure they have sufficient material left to prevent metal-to-metal contact.

- Rotor condition: Inspect the brake rotors for any cracks, warping, or excessive wear that may affect braking performance.

- Caliper function: Check if the brake calipers are moving freely and not sticking, which could lead to uneven wear or reduced braking efficiency.

8. Describe your experience in using tire pressure monitoring systems (TPMS).

Understanding TPMS

- Explain the purpose and importance of TPMS in maintaining proper tire inflation.

- Describe the different types of TPMS systems and how they work.

TPMS servicing

- Explain the procedures for installing, programming, and servicing TPMS sensors.

- Describe how to identify and troubleshoot common TPMS faults.

9. What are the common causes of tire failure and how can they be prevented?

- Underinflation: Maintaining proper tire pressure is crucial to prevent premature wear, blowouts, and increased rolling resistance.

- Overinflation: Excessive tire pressure can lead to uneven wear, reduced traction, and a harsh ride.

- Uneven wear: Misalignment, suspension problems, or improper tire rotation can cause uneven wear patterns, reducing tire life and performance.

- Sidewall damage: Impacts, curbs, or potholes can damage the tire sidewall, compromising its integrity and safety.

- Aging: Tires naturally degrade over time due to exposure to sunlight, temperature changes, and chemical reactions, reducing their performance and safety.

10. How do you handle customer concerns or complaints related to tire services?

- Active listening: Listen attentively to the customer’s concerns and acknowledge their perspective.

- Assessment: Evaluate the issue and identify potential causes or solutions.

- Communication: Explain the findings and proposed solutions clearly and professionally.

- Resolution: Work with the customer to find a mutually agreeable resolution that addresses their concerns.

- Follow-up: Follow up with the customer after the service to ensure their satisfaction and address any additional questions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Installers are responsible for the safe and efficient installation, balancing, and maintenance of tires on various vehicles.

1. Tire Installation

Installing tires onto vehicles, using specialized equipment and techniques.

- Inspecting and preparing tires for installation

- Mounting tires on rims and inflating them to specifications

2. Tire Balancing

Balancing tires to ensure even distribution of weight, reduce vibration, and extend tire life.

- Using balancing machines to detect and correct any imbalances

- Adding weights to tires as needed to achieve optimal balance

3. Tire Maintenance

Inspecting and maintaining tires to identify and resolve potential issues.

- Checking tire pressure and adjusting as necessary

- Identifying and repairing tire punctures or other damage

- Inspecting tire treads for wear and recommending replacements when necessary

4. Customer Service

Providing exceptional customer service by addressing customer inquiries, answering questions, and resolving any concerns.

- Explaining proper tire care and maintenance to customers

- Making recommendations for tire selection based on customer needs

- Ensuring customer satisfaction with tire installation and maintenance services

Interview Tips

Preparing for a Tire Installer interview involves understanding the key job responsibilities, researching the company, and practicing common interview questions.

1. Research the Company

Visit the company website to learn about their products, services, and values. This knowledge will help you align your answers to the company’s culture and demonstrate your interest in the role.

- Research the company’s history, mission, and vision

- Identify any recent news or industry-related information about the company

2. Practice Common Interview Questions

Prepare answers to typical interview questions related to tire installation and customer service. By rehearsing these answers, you can deliver them confidently and concisely during the interview.

- Q: Describe your experience installing and balancing tires.

- Q: What is your approach to providing excellent customer service?

- Q: How do you handle situations where customers have concerns about tire installation?

- Q: What are your strengths and weaknesses as a Tire Installer?

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Use specific examples to demonstrate your abilities and how they have benefited previous employers.

- Highlight your proficiency in using tire installation equipment

- Provide examples of your attention to detail and commitment to safety

4. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your interest in the role and the company. These questions can also provide valuable information about the company’s culture and expectations.

- Q: What are the company’s growth and advancement opportunities for Tire Installers?

- Q: What is the company’s commitment to employee training and development?

- Q: How does the company measure success for Tire Installers?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tire Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.