Are you gearing up for an interview for a Track Surfacing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Track Surfacing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

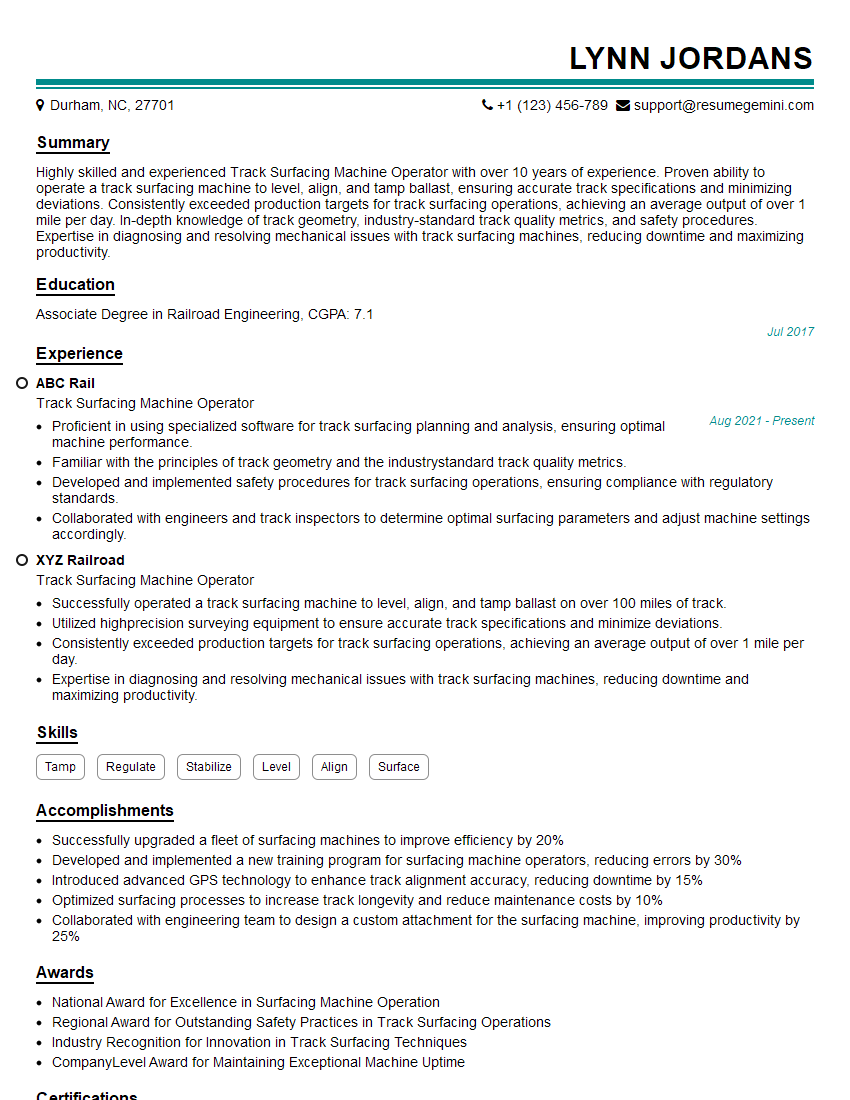

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Surfacing Machine Operator

1. How do you plan and prepare for track surfacing operations, including determining materials, equipment, and crew requirements?

To plan and prepare for track surfacing operations, I start by assessing the condition of the track, including the level of wear, deformation, and any defects. Based on this assessment, I determine the necessary materials, such as ballast, tamping material, and rails. I also assess the required equipment, including tampers, ballast regulators, and track liners. Finally, I determine the crew requirements, considering the size of the project and the complexity of the work.

2. How do you ensure the proper alignment, leveling, and tamping of the track during surfacing operations?

Alignment and Leveling

- I use lasers and other leveling devices to ensure the proper alignment and leveling of the track.

- I continually monitor the track geometry throughout the surfacing process to make any necessary adjustments.

Tamping

- I use tampers to compact the ballast under and around the ties.

- I adjust the tamping pressure and depth to ensure that the ballast is properly compacted and provides adequate support for the track.

3. How do you operate and maintain the track surfacing machine, including troubleshooting and repairing any malfunctions?

Operation

- I am proficient in operating all types of track surfacing machines.

- I follow safety procedures and guidelines to ensure the safe operation of the machine.

Maintenance and Troubleshooting

- I perform regular maintenance on the track surfacing machine to keep it in good working condition.

- I am able to troubleshoot and repair most common malfunctions that occur with the machine.

4. How do you manage the track surfacing crew, including assigning tasks, monitoring progress, and ensuring safety?

- I assign tasks to crew members based on their skills and experience.

- I monitor the progress of the crew to ensure that the work is being completed on time and to the required standards.

- I ensure that all crew members follow safety procedures and wear appropriate protective gear.

5. How do you coordinate with other departments, such as engineering and maintenance, to ensure that track surfacing operations are completed efficiently and effectively?

- I work closely with engineering to ensure that track surfacing operations are in accordance with the design specifications.

- I coordinate with maintenance to ensure that the track is properly prepared for surfacing and that any necessary repairs are completed.

6. How do you stay up-to-date on the latest techniques and technologies in track surfacing?

- I attend industry conferences and workshops to learn about new techniques and technologies.

- I read trade publications and technical manuals to stay informed about the latest developments in the field.

7. How do you ensure that track surfacing operations are completed safely and efficiently?

- I develop and implement a safety plan for each track surfacing project.

- I train my crew on the safety plan and ensure that they follow all safety procedures.

- I use efficient work methods and equipment to complete the work quickly and to a high standard.

8. How do you handle challenges and unexpected situations that may arise during track surfacing operations?

- I assess the situation and develop a plan to address the challenge or unexpected situation.

- I communicate with my crew and other departments to ensure that everyone is aware of the situation and is working together to resolve it.

- I take the necessary steps to ensure that the work is completed safely and efficiently, even in challenging situations.

9. How do you prioritize tasks and manage your time effectively during track surfacing operations?

- I identify the most important tasks that need to be completed and focus on those first.

- I break down large tasks into smaller, more manageable tasks.

- I use a variety of tools and techniques to stay organized and manage my time effectively.

10. How do you measure and evaluate the success of track surfacing operations?

- I use a variety of metrics to measure the success of track surfacing operations, including track geometry, ride quality, and safety.

- I compare the results of my work to industry standards and best practices.

- I seek feedback from my crew and other departments to identify areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Surfacing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Surfacing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Track Surfacing Machine Operators are responsible for the operation and maintenance of track surfacing machines, which are used to level and align railroad tracks. They must have a strong understanding of the principles of track geometry and be able to operate the machine safely and efficiently.

1. Operate track surfacing machines

Operate track surfacing machines to level, align, and tamp ballast under railroad tracks.

- Follow established procedures and specifications to ensure proper operation of the machine.

- Monitor machine performance and make adjustments as necessary to maintain optimal performance.

2. Maintain track surfacing machines

Perform routine maintenance on track surfacing machines, including lubrication, cleaning, and minor repairs.

- Inspect machines regularly to identify potential problems and make necessary repairs.

- Keep accurate records of maintenance performed.

3. Supervise other operators

Supervise other operators and ensure that they are following proper procedures and safety guidelines.

- Provide training and guidance to new operators.

- Monitor operator performance and provide feedback.

4. Other duties

Perform other duties as assigned, such as assisting with track inspections or repairs.

- Maintain a clean and organized work area.

- Follow all safety regulations and procedures.

Interview Tips

Preparing for an interview for a Track Surfacing Machine Operator position requires research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the company and the position

Research the company’s website, LinkedIn profile, and Glassdoor reviews to learn about their culture, values, and recent projects. This will help you understand the company’s needs and how you can contribute to their team.

- Identify the key responsibilities of the Track Surfacing Machine Operator position and make sure you have the necessary skills and experience.

2. Practice your answers to common interview questions

Practice answering common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses?” Prepare specific examples from your experience that demonstrate your skills and abilities.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide clear and concise examples.

3. Be prepared to discuss your experience and skills

Highlight your experience operating and maintaining track surfacing machines. Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous projects.

- Discuss your knowledge of track geometry and your ability to operate the machine safely and efficiently.

4. Ask questions about the company and the position

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company.

- Prepare questions about the company’s growth plans, their safety record, and their commitment to employee development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Track Surfacing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!