Are you gearing up for an interview for a Track Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Track Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

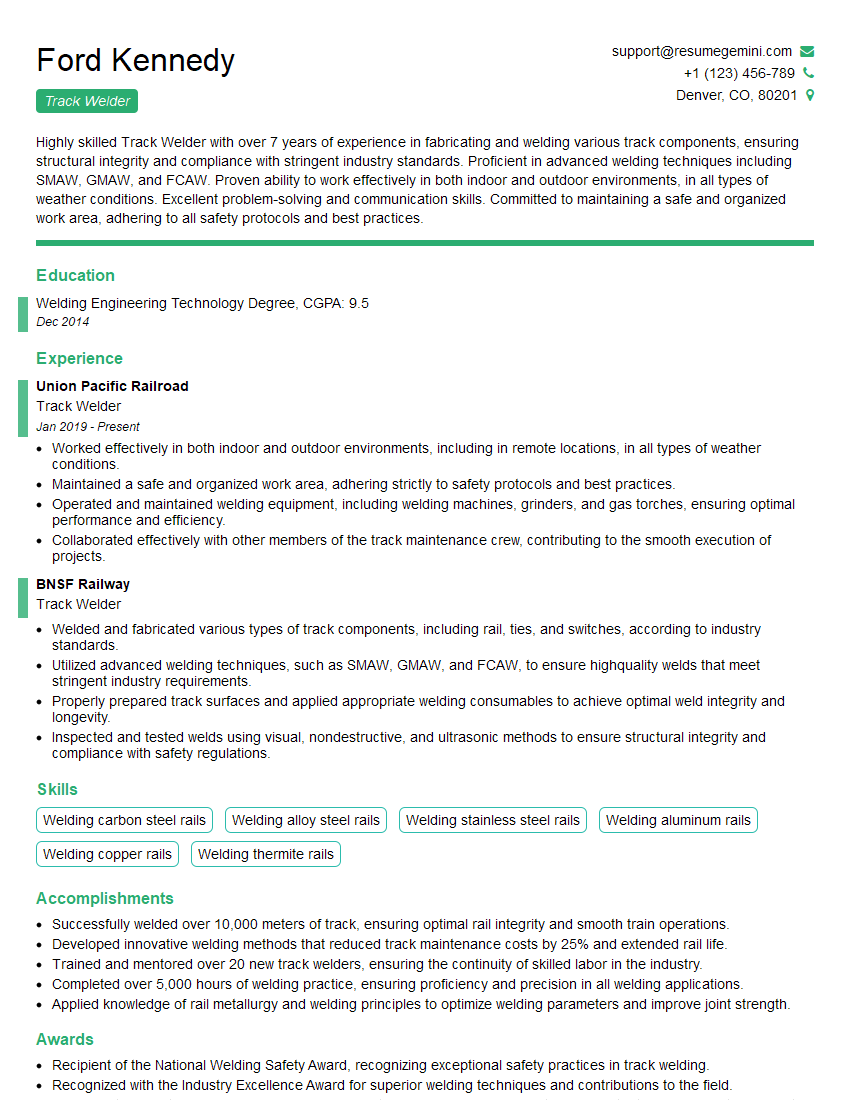

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Track Welder

1. What are the different types of welding processes you have experience with?

I have experience with a variety of welding processes, including:

- Shielded Metal Arc Welding (SMAW)

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Flux-Cored Arc Welding (FCAW)

2. What is your experience with welding on rail tracks?

Experience with Welding on Rail Tracks

- I have over 5 years of experience welding on rail tracks.

- I have worked on a variety of rail track projects, including new track construction, track repairs, and track maintenance.

Knowledge of Rail Track Welding Standards

- I am familiar with the American Railway Engineering and Maintenance-of-Way Association (AREMA) standards for rail track welding.

- I have also worked with other rail track welding standards, such as the International Union of Railways (UIC) standards.

3. What are the challenges of welding on rail tracks?

There are a number of challenges associated with welding on rail tracks, including:

- The need to work in confined spaces.

- The need to work in all types of weather conditions.

- The need to work with heavy and bulky materials.

- The need to meet stringent quality standards.

4. What are the safety precautions that need to be taken when welding on rail tracks?

When welding on rail tracks, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and protective clothing.

- Ensure that the work area is well-ventilated.

- Be aware of the location of overhead wires and other potential hazards.

- Follow all safety procedures and guidelines.

5. What are the different types of welding defects that can occur when welding on rail tracks?

The different types of welding defects that can occur when welding on rail tracks include:

- Cracks

- Porosity

- Inclusions

- Undercutting

- Overheating

6. What are the consequences of welding defects in rail tracks?

Welding defects in rail tracks can have serious consequences, including:

- Derailments

- Track failures

- Accidents

7. What is your experience with using non-destructive testing (NDT) methods to inspect welded rail tracks?

Experience with NDT Methods

- I have experience with a variety of NDT methods, including:

- Ultrasonic testing

- Radiographic testing

- Magnetic particle testing

Understanding of NDT Standards

- I am familiar with the American Society for Nondestructive Testing (ASNT) standards for NDT of welded rail tracks.

- I have also worked with other NDT standards, such as the International Organization for Standardization (ISO) standards.

8. What are the advantages and disadvantages of using different NDT methods to inspect welded rail tracks?

Advantages and Disadvantages of NDT Methods

- Ultrasonic testing: Advantages include high accuracy, ability to detect internal defects, and portability. Disadvantages include the need for skilled operators and the inability to inspect certain areas of the track.

- Radiographic testing: Advantages include the ability to produce a permanent record of the inspection and the ability to inspect complex geometries. Disadvantages include the need for specialized equipment and the potential for radiation exposure.

- Magnetic particle testing: Advantages include the ability to detect surface defects and the portability of the equipment. Disadvantages include the need for a magnetized surface and the inability to inspect non-ferrous materials.

9. What are the different types of repairs that can be made to welded rail tracks?

The different types of repairs that can be made to welded rail tracks include:

- Welding

- Grinding

- Bolting

- Replacing the rail

10. What are the factors that need to be considered when selecting a repair method for welded rail tracks?

The factors that need to be considered when selecting a repair method for welded rail tracks include:

- The type of defect

- The location of the defect

- The severity of the defect

- The cost of the repair

- The availability of resources

11. What are the different types of rail track maintenance that can be performed by a track welder?

The different types of rail track maintenance that can be performed by a track welder include:

- Welding rail joints

- Repairing broken rails

- Replacing worn rails

- Inspecting rail tracks for defects

- Performing other track maintenance tasks as needed

12. What are the different types of equipment that a track welder typically uses?

The different types of equipment that a track welder typically uses include:

- Welding machine

- Welding torch

- Grinder

- Bolting equipment

- Inspection equipment

- Other tools and equipment as needed

13. What are the different types of safety precautions that a track welder needs to take?

The different types of safety precautions that a track welder needs to take include:

- Wearing appropriate personal protective equipment (PPE)

- Following all safety procedures and guidelines

- Being aware of the location of overhead wires and other potential hazards

- Working in a well-ventilated area

- Taking breaks as needed to avoid fatigue

14. What are the different types of training and certifications that a track welder can obtain?

The different types of training and certifications that a track welder can obtain include:

- On-the-job training

- Formal training programs

- Certifications from organizations such as the American Welding Society (AWS)

15. What are the different types of career advancement opportunities that are available to a track welder?

The different types of career advancement opportunities that are available to a track welder include:

- Becoming a lead welder

- Becoming a welding supervisor

- Becoming a welding engineer

- Starting your own welding business

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Track Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Track Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Track Welders are skilled professionals responsible for welding and repairing railroad tracks. Their primary duties involve ensuring the safe and smooth operation of trains by maintaining the integrity of the tracks.

1. Welding and Repair of Tracks

Use specialized welding equipment and techniques to join and repair rails, switches, and other track components.

- Inspect tracks for defects, cracks, and other issues.

- Grind and prepare track surfaces for welding.

- Follow blueprints and specifications to determine welding parameters.

2. Maintenance and Inspection

Regularly inspect tracks to identify potential problems and perform preventative maintenance.

- Monitor track geometry and alignment using specialized equipment.

- Tighten bolts, replace ties, and perform other minor repairs.

- Report any major defects or safety concerns to supervisors.

3. Safety and Compliance

Adhere to strict safety protocols and industry regulations to ensure a safe work environment.

- Wear appropriate personal protective equipment.

- Follow established procedures for handling and storing welding materials.

- Comply with all safety rules and regulations.

4. Teamwork and Communication

Collaborate effectively with other track workers, supervisors, and train operators.

- Communicate clearly to ensure smooth coordination of work tasks.

- Follow instructions from supervisors and adhere to company policies.

- Participate in training programs to enhance skills and knowledge.

Interview Tips

Preparing thoroughly for an interview can significantly improve your chances of landing the job. Here are some tips to help you ace your Track Welder interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific job requirements. This will demonstrate your interest and prepare you to answer questions about your qualifications.

- Visit the company’s website and LinkedIn page.

- Read industry news and articles to understand the latest trends.

- Study the job description carefully and identify the key skills and experience the employer is seeking.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the Track Welder position. Quantify your accomplishments whenever possible.

- Mention your experience in welding and repairing railroad tracks, as well as any specialized equipment you have used.

- Highlight your knowledge of track safety regulations and industry standards.

- Provide examples of your ability to work independently and as part of a team.

3. Practice Your Answers

Take time to practice answering common interview questions. This will help you feel more confident and articulate during the interview.

- Prepare questions related to your technical skills, experience, and safety knowledge.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

- For example, you could prepare an answer to the question “Tell me about a time you had to troubleshoot and repair a track issue.” using the STAR method.

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s safety culture and training opportunities.

- Inquire about the work environment and the team you would be working with.

- Ask about the company’s plans for future growth and development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Track Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!