Feeling lost in a sea of interview questions? Landed that dream interview for Tray Casting Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tray Casting Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

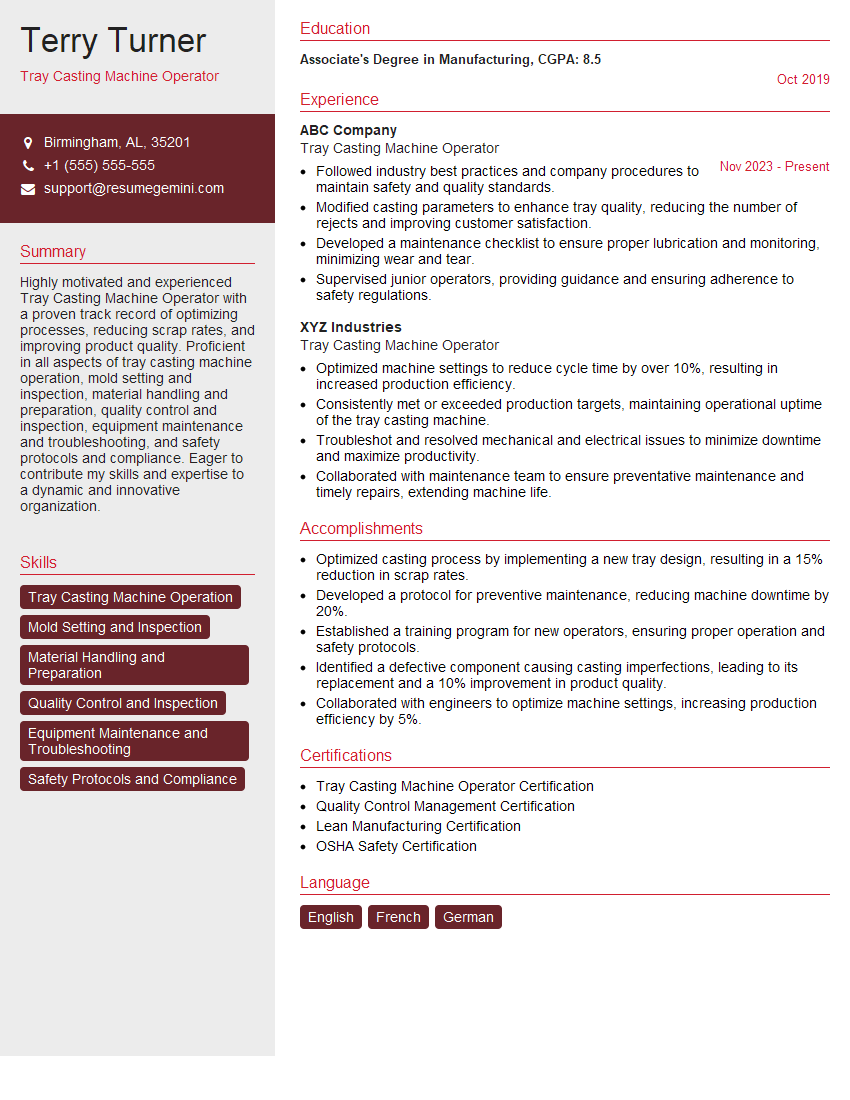

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tray Casting Machine Operator

1. What are the key responsibilities of a Tray Casting Machine Operator?

- Operate and monitor tray casting machines to produce trays of various sizes and materials.

- Set up and adjust machines according to specifications, ensuring optimal operation and product quality.

2. Explain the process of casting trays using the machine.

Raw Material Preparation

- Select and prepare the appropriate raw material (e.g., aluminum, steel) for casting.

- Check material properties and ensure they meet specifications.

Machine Setup

- Install the mold and die according to product specifications.

- Adjust machine settings, such as temperature, pressure, and cooling rate.

Casting Process

- Pour molten material into the mold.

- Apply pressure to the mold to form the desired shape.

- Control cooling rate to achieve the desired material properties.

Post-Casting

- Remove the cast tray from the mold.

- Perform quality inspections to ensure product meets specifications.

3. How do you ensure the quality of the trays produced?

- Adhere to established quality standards and specifications.

- Perform regular machine maintenance and calibration to maintain accuracy.

- Monitor production parameters (e.g., temperature, pressure) to identify and address deviations.

4. What types of maintenance tasks are associated with tray casting machines?

- Regular cleaning and lubrication of machine components.

- Replacement of worn or damaged parts (e.g., molds, dies, sensors).

- Calibration of machine settings to ensure accuracy and consistency.

5. How do you troubleshoot common problems that may arise during tray casting?

- Identify the source of the problem (e.g., machine malfunction, material issues).

- Analyze and interpret error messages or indicators.

- Implement corrective actions to resolve the issue and minimize downtime.

6. Describe the safety precautions that must be observed when operating tray casting machines.

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses).

- Follow established safety protocols for machine operation.

- Identify and mitigate potential hazards in the work environment.

7. How do you stay up-to-date with the latest advancements in tray casting technology?

- Attend industry conferences and workshops.

- Read trade publications and technical articles.

- Participate in training programs offered by equipment manufacturers.

8. What specific skills or certifications do you possess that make you a suitable candidate for this role?

- Proficient in operating tray casting machines and related equipment.

- Strong understanding of casting processes and material properties.

- Possession of relevant certifications (e.g., Certified Molding Technician).

9. How do you manage multiple tasks and prioritize your workload when working with tight deadlines?

- Prioritize tasks based on urgency and importance.

- Use time management techniques (e.g., scheduling, delegation).

- Maintain clear and effective communication with supervisors and colleagues.

10. Can you provide an example of a time when you successfully resolved a complex issue with a tray casting machine?

Describe the situation, the steps you took to diagnose and resolve the issue, and the outcome.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tray Casting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tray Casting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tray Casting Machine Operator is a crucial role in the manufacturing industry, with the primary responsibility of operating and maintaining tray casting machines to create various products. The key job responsibilities include:

1. Machine Operation

The operator is responsible for the safe and efficient operation of the tray casting machine, ensuring it runs smoothly and produces consistent, high-quality products.

- Setting up and calibrating the machine according to production requirements.

- Monitoring machine operation, including speed, temperature, and pressure.

2. Product Handling

The operator is involved in handling the raw materials and finished products, ensuring proper handling and preventing damage.

- Loading raw materials into the machine and unloading finished products.

- Inspecting products for defects and ensuring they meet quality standards.

3. Machine Maintenance

Regular maintenance is crucial to ensure the machine’s optimal performance and prevent breakdowns. The operator is responsible for basic maintenance tasks.

- Cleaning and lubricating machine components.

- Adjusting and replacing worn-out parts.

4. Quality Control

The operator plays a role in maintaining product quality by monitoring the casting process and identifying any potential issues.

- Monitoring product dimensions and other quality parameters.

- Adjusting machine settings to minimize defects.

Interview Tips

Thorough preparation is key to acing an interview for a Tray Casting Machine Operator position. Here are some tips to help you prepare:

1. Research the Company and Role

Take time to research the company and the specific role. This will give you a good understanding of their values, goals, and the responsibilities you will be expected to fulfill.

- Visit the company’s website to learn about their history, products, and mission.

- Read the job description carefully to understand the key requirements and expectations.

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your experience and skills that are relevant to the role. These may include:

- Experience in operating casting machines, preferably tray casting machines.

- Knowledge of casting processes and quality control procedures.

- Strong mechanical aptitude and problem-solving skills.

3. Prepare for Common Interview Questions

Practice answering common interview questions related to your experience, skills, and motivations. Some likely questions include:

- “Tell me about your experience in operating tray casting machines.”

- “How do you ensure the quality of products produced on the casting machine?”

- “What are your strengths and weaknesses as a Tray Casting Machine Operator?”

4. Ask Informed Questions

Asking thoughtful questions during the interview shows your interest and engagement. Prepare questions about the company, the role, and the industry. Consider asking about:

- The company’s growth plans and future projects.

- Opportunities for training and professional development.

- The company’s commitment to safety and sustainability.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tray Casting Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tray Casting Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.