Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Trencher Driver position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

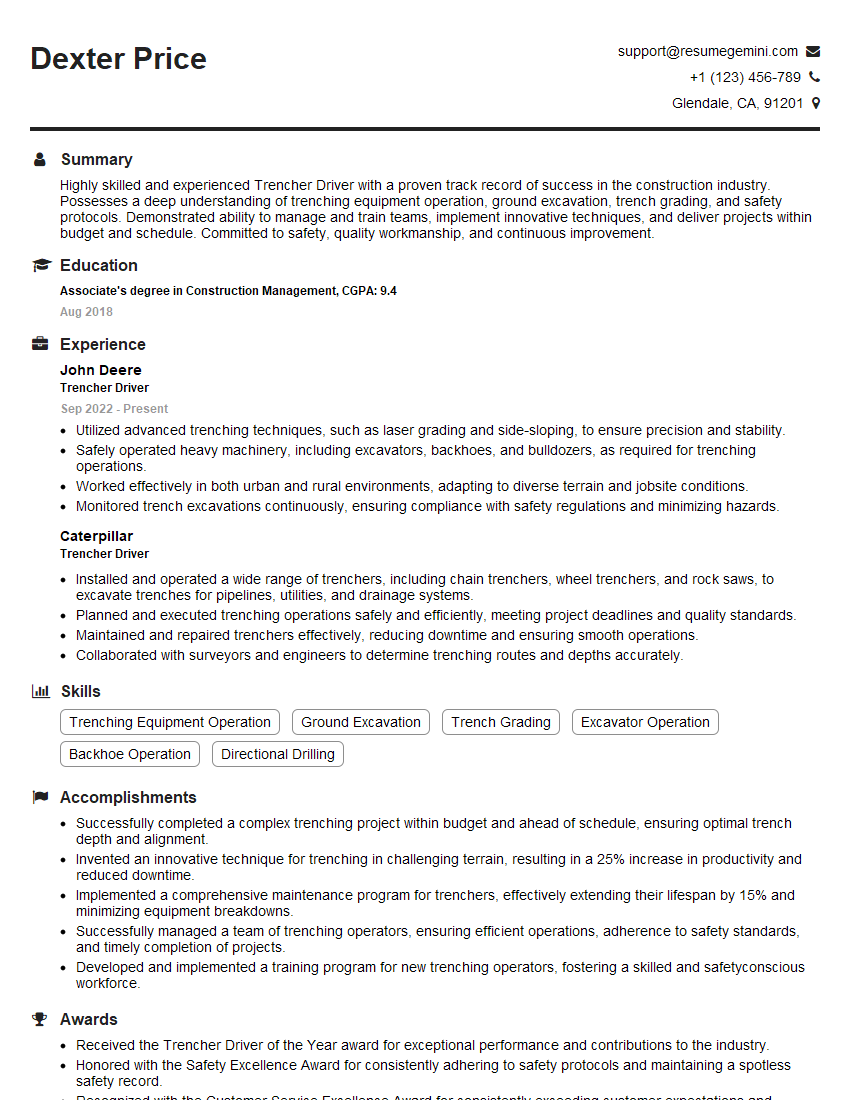

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trencher Driver

1. How would you determine the correct depth and width of the trench for the installation of underground utilities?

To determine the correct depth and width of the trench for the installation of underground utilities, I would consider the following factors:

- Type and size of the utilities being installed

- Soil conditions and compaction

- Local codes and regulations

- Depth to other existing utilities

- Accessibility for maintenance and repair

2. Explain the steps involved in operating a trencher machine safely and efficiently.

Pre-Operation Checks

- Inspect the machine for any damage or leaks

- Check fluid levels and top up as necessary

- Ensure that the digging chain and teeth are sharp

- Put on appropriate safety gear including gloves, eye protection, and earplugs

Operation

- Start the machine and allow it to warm up

- Set the desired trench depth and width

- Position the trencher over the desired location

- Engage the digging chain and slowly advance the machine

- Monitor the trench depth and width frequently

- Avoid hitting underground obstacles

Post-Operation

- Disengage the digging chain and stop the machine

- Clean the machine and inspect it for any damage

- Store the machine in a safe and dry location

3. How do you ensure that the trench is graded properly before laying the utilities?

To ensure that the trench is graded properly before laying the utilities, I would use a level or laser level to establish the desired grade. I would then use a grader or hand tools to shape the trench bottom to the required grade. Once the trench is graded, I would compact the soil to provide a stable base for the utilities.

4. Describe the different types of soil conditions you have encountered while operating a trencher and how you adjusted your digging technique accordingly.

I have encountered various soil conditions while operating a trencher, including:

- Loose soil: In loose soil, I use a wider trench and dig at a slower speed to prevent the soil from collapsing.

- Hard soil: In hard soil, I use a narrower trench and dig at a faster speed to break through the soil.

- Rocky soil: In rocky soil, I use a trencher with a rock cutting attachment and dig at a slower speed to avoid damaging the machine.

- Wet soil: In wet soil, I use a trencher with a dewatering system to remove excess water from the trench.

5. How do you identify and avoid underground obstacles such as existing utilities, rocks, and tree roots?

To identify and avoid underground obstacles, I use the following techniques:

- Utility locates: I obtain utility locates from the local utility companies to identify the location of existing utilities.

- Potholing: I use a potholing tool to dig small holes in the ground to identify the presence of underground obstacles.

- Hand digging: I use hand tools to carefully dig around underground obstacles to avoid damaging them.

6. How do you maintain a trencher machine to ensure optimal performance and safety?

To maintain a trencher machine to ensure optimal performance and safety, I perform the following tasks:

- Regular inspections: I inspect the machine daily for any damage or leaks.

- Fluid changes: I change the engine oil, hydraulic oil, and other fluids according to the manufacturer’s recommendations.

- Filter replacements: I replace the air filter, fuel filter, and hydraulic filter regularly.

- Sharpening: I sharpen the digging chain and teeth regularly to ensure optimal cutting performance.

- Safety checks: I check the safety features of the machine, such as the emergency stop button and the guarding, regularly to ensure that they are functioning properly.

7. How do you handle unexpected situations or emergencies while operating a trencher machine?

To handle unexpected situations or emergencies while operating a trencher machine, I follow these steps:

- Stay calm: I remain calm and assess the situation.

- Stop the machine: I disengage the digging chain and stop the machine.

- Identify the hazard: I identify the source of the problem.

- Take appropriate action: I take appropriate action to address the hazard, such as repairing a leak or calling for assistance.

8. How do you collaborate with other team members to ensure a safe and efficient work environment on a trenching project?

To collaborate with other team members to ensure a safe and efficient work environment on a trenching project, I:

- Communicate effectively: I communicate clearly and regularly with other team members to ensure that everyone is aware of the plan and any potential hazards.

- Share information: I share information about the site conditions, trenching progress, and any obstacles with other team members.

- Work together: I work together with other team members to identify and address any potential problems, and to ensure that the project is completed safely and efficiently.

9. How do you stay up-to-date on the latest industry best practices and safety regulations for trenching operations?

To stay up-to-date on the latest industry best practices and safety regulations for trenching operations, I:

- Attend industry conferences and workshops: I attend industry conferences and workshops to learn about the latest best practices and safety regulations.

- Read industry publications: I read industry publications to stay informed about the latest trends and developments in trenching operations.

- Consult with experts: I consult with experts in the field to get advice and guidance on best practices and safety regulations.

10. How do you maintain a positive and professional attitude in a challenging work environment?

To maintain a positive and professional attitude in a challenging work environment, I:

- Stay focused on my goals: I stay focused on my goals and the task at hand, and I don’t let setbacks or challenges get me down.

- Stay positive: I maintain a positive attitude and look for the good in every situation.

- Be respectful: I treat my colleagues and other team members with respect, even when under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trencher Driver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trencher Driver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trencher drivers are responsible for the safe and efficient operation of trenching machines. They typically work on construction sites, excavating trenches for pipelines, cables, and other utilities. Key responsibilities include:

1. Operating Trenching Machines

Trencher drivers must be skilled in operating trenching machines of various sizes and configurations. This includes understanding the controls, setting up the machine, and operating it safely and efficiently.

- Preparing the trenching machine for operation, such as checking fluids, inspecting the machine, and ensuring it is in good working order.

- Operating the trenching machine to excavate trenches to specifications, including depth, width, and slope.

2. Maintaining Trenching Machines

Trencher drivers are also responsible for maintaining their machines. This includes performing routine inspections, cleaning, and lubrication, as well as making minor repairs.

- Performing daily maintenance checks on the trencher, such as checking fluid levels, inspecting belts and hoses, and greasing moving parts.

- Making minor repairs to the trencher, such as replacing belts, hoses, or filters.

3. Ensuring Safety

Trencher drivers must follow all safety regulations and procedures to ensure the safety of themselves and others on the job site.

- Wearing appropriate personal protective equipment (PPE), such as hard hats, safety glasses, and gloves.

- Following all safety procedures, such as using proper barricades, warning signs, and flaggers.

4. Working with Others

Trencher drivers often work with other construction workers, such as laborers, pipefitters, and electricians. They must be able to communicate effectively and work as a team to complete projects safely and efficiently.

- Communicating with other workers on the job site, such as laborers, pipefitters, and electricians.

- Working as a team to complete projects safely and efficiently.

Interview Tips

To ace an interview for a trencher driver position, it is important to prepare thoroughly and demonstrate your skills and experience. Here are some tips:

1. Research the Company

Before your interview, take the time to research the company you are applying to. This will help you understand their business, their culture, and the specific requirements of the position you are seeking.

- Visit the company’s website to learn about their products, services, and history.

- Read news articles and press releases to get a sense of the company’s recent developments and goals.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview.

- Write down your answers to questions such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice your answers out loud to ensure you are clear and concise.

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience that are relevant to the trencher driver position.

- Emphasize your experience operating trenching machines of various sizes and configurations.

- Highlight your ability to maintain trenching machines and make minor repairs.

- Showcase your commitment to safety and your ability to work as a team.

4. Ask Questions

At the end of your interview, be sure to ask the interviewer questions. This shows that you are interested in the position and the company.

- Ask questions about the company’s culture, the specific responsibilities of the position, and the training and development opportunities available.

- Asking questions also gives you an opportunity to learn more about the company and the position to see if it is a good fit for you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Trencher Driver interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!