Are you gearing up for an interview for a Trenching Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Trenching Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

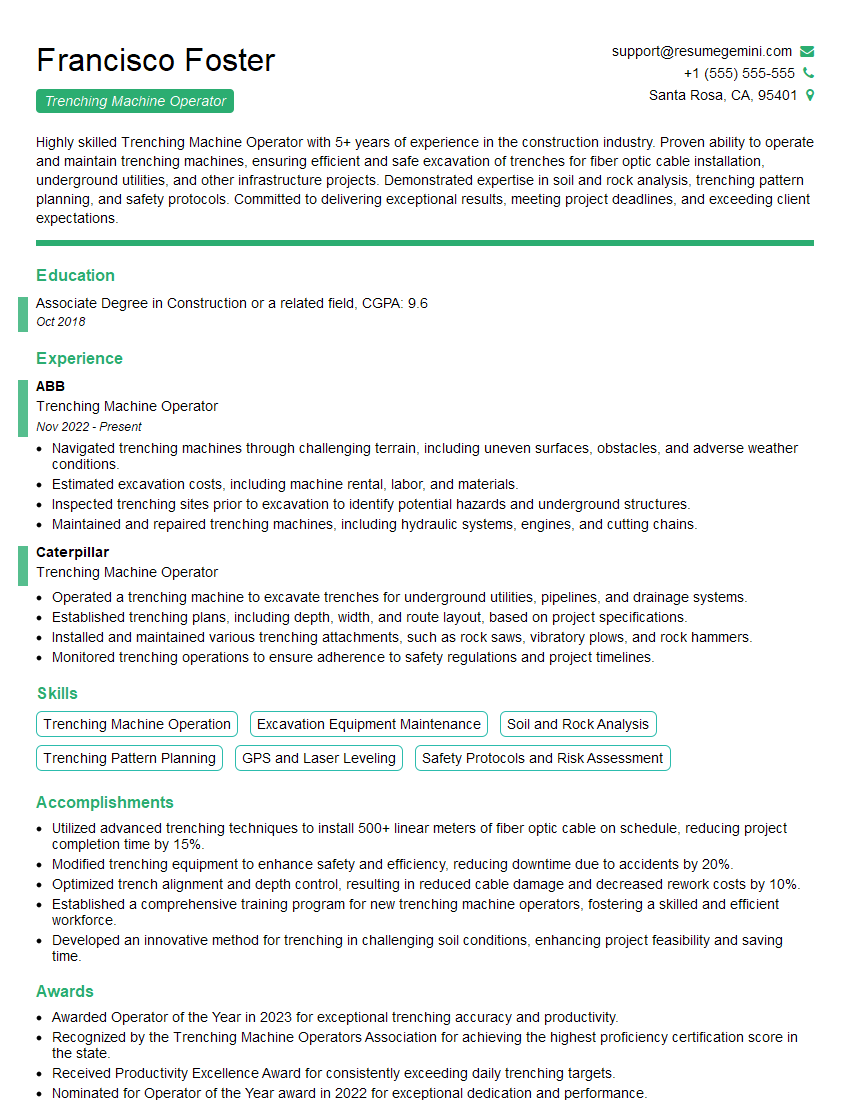

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Trenching Machine Operator

1. Tell me about your experience in operating trenching machines?

I have extensive experience as a Trenching Machine Operator, with over [number] years in the industry. I am highly skilled in operating various types of trenching machines, including walk-behind, ride-on, and mini excavators.

2. What are the key safety precautions you take when operating a trenching machine?

Safety First

- Always wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Inspect the trenching machine thoroughly before each use, paying close attention to the blade and drive system.

Site Safety

- Ensure that the trenching area is clear of obstacles and utilities.

- Set up barricades and warning signs to alert others of the work area.

Operating Safety

- Never operate a trenching machine while under the influence of drugs or alcohol.

- Maintain a safe distance from others and avoid operating the trenching machine near open flames.

3. How do you determine the appropriate depth and width of a trench for a specific project?

- The depth of the trench should be sufficient to accommodate the pipe or cable being installed, plus any additional material required for bedding and backfill.

- The width of the trench should be wide enough to allow for easy installation and maintenance of the pipe or cable.

- I also consider factors such as soil conditions, ground water levels, and the presence of any obstacles or utilities.

4. What are the different types of soil conditions you have encountered, and how do they affect trenching operations?

- Hard Soil: Requires specialized equipment and techniques to break through, such as rock drills or hydraulic hammers.

- Loose Soil: Can be more difficult to trench in, as it tends to cave in and require more frequent shoring.

- Wet Soil: Requires proper drainage and dewatering measures to prevent flooding and ensure stability.

- Frozen Soil: Requires special equipment, such as heated blades or thaw bars, to cut through.

5. How do you handle trenching operations in areas with existing underground utilities?

- Always request and review utility locates before digging.

- Hand-dig carefully near marked utilities to avoid damage.

- Use trenchless methods, such as directional boring, when feasible.

- Protect exposed utilities with sheathing or padding.

6. What are some common problems that can occur during trenching operations, and how do you troubleshoot and resolve them?

- Broken Blade: Replace the blade immediately and inspect the machine for any other damage.

- Clogged Discharge Chute: Clear the blockage and ensure that the chute is properly aligned.

- Engine Overheating: Stop the machine, allow it to cool, and check for any leaks or obstructions in the cooling system.

- Hydraulic Leak: Identify the source of the leak and tighten or replace any damaged components.

7. How do you ensure that the trench is properly backfilled and compacted to meet safety and quality standards?

- Use appropriate backfill material, such as sand, gravel, or topsoil.

- Compact the backfill in layers using a hand tamper or mechanical compactor.

- Ensure that the backfill is properly sloped and graded to prevent erosion.

- Restore the surface to its original condition, including removing any excess material or debris.

8. What is your experience with using different types of attachments and accessories for trenching machines?

- Augers: Used for drilling holes for poles or foundations.

- Backfill Blades: Used for filling and grading trenches.

- Rippers: Used for breaking up hard soil or rock.

- Vibratory Plates: Used for compacting backfill.

9. How do you maintain and service trenching machines to ensure optimal performance and safety?

- Regular Inspections: Check for loose bolts, leaks, and any other signs of wear and tear.

- Blade Sharpening: Keep blades sharp to ensure clean cuts and prevent premature wear.

- Hydraulic Maintenance: Check and change hydraulic fluid and filters as per manufacturer’s recommendations.

- Lubrication: Grease and oil all moving parts regularly to prevent friction and wear.

10. How do you stay up-to-date with the latest advancements in trenching technology and best practices?

- Attend industry conferences and trade shows.

- Read industry publications and technical journals.

- Participate in online forums and discussion groups.

- Seek training and certifications from equipment manufacturers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Trenching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Trenching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Trenching Machine Operators play a crucial role in digging trenches for various infrastructure projects. Their main duties involve:

1. Operating Trenching Machine

Operate trenching machines to create trenches for laying pipes, cables, and other underground utilities.

2. Setup and Maintenance

Set up, maintain, and repair trenching machines, ensuring they operate efficiently.

3. Site Preparation

Prepare job sites, removing obstacles, and marking trench locations based on plans and specifications.

4. Safety Compliance

Adhere to workplace safety regulations, wearing appropriate safety gear and following protocols.

Interview Tips

To prepare effectively for a Trenching Machine Operator interview, consider the following:

1. Research the Company and Role

Familiarize yourself with the company’s background, projects, and industry reputation. Research the specific responsibilities of the Trenching Machine Operator role to understand the expectations.

2. Highlight Relevant Experience

Emphasize your previous experience operating trenching machines, your proficiency in machine setup and maintenance, and your adherence to safety protocols.

3. Prepare for Technical Questions

Expect questions about your knowledge of trenching machines, their components, and troubleshooting. You may also face questions related to trenching techniques and safety procedures.

4. Showcase Problem-Solving Skills

Share examples of how you have addressed challenges on the job, such as dealing with unexpected ground conditions or equipment malfunctions. Highlight your ability to make quick decisions and resolve issues efficiently.

5. Be Punctual and Professional

Arrive at the interview on time, dress appropriately, and maintain a positive and enthusiastic demeanor. Demonstrate your professionalism and respect for the interviewer and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Trenching Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Trenching Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.