Are you gearing up for a career in Tube Building Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tube Building Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

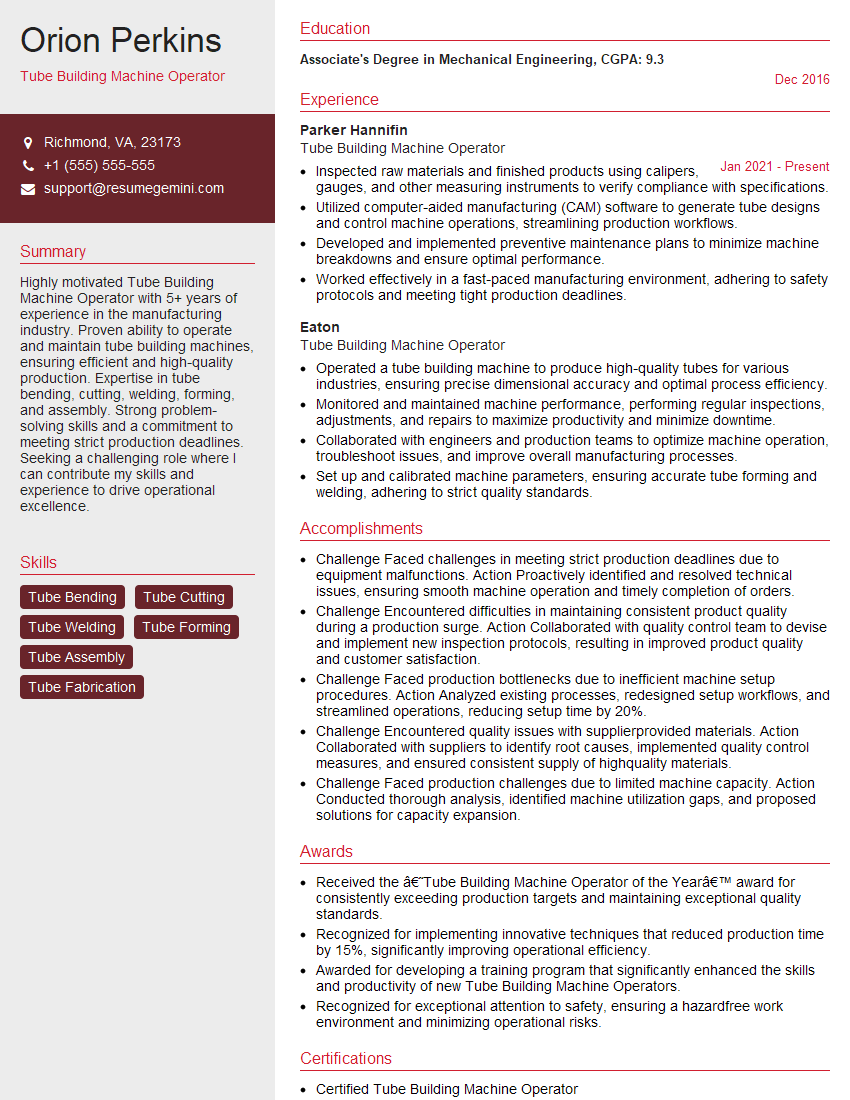

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tube Building Machine Operator

1. What is the difference between a draw bench and a tube welding machine?

- Draw bench uses a die to pull the tube through to reduce its diameter and increase its length.

- Tube welding machine uses heat to join two edges of the metal strip to form a tube.

2. What are the key parameters to consider when setting up a tube building machine?

Tube material

- Tensile strength

- Yield strength

- Elongation

Tube dimensions

- Diameter

- Wall thickness

- Length

3. What are the common defects that can occur during tube building and how can you prevent them?

- Wrinkles: Caused by insufficient tension during forming. Prevented by using proper tension settings and ensuring that the material is adequately heated.

- Splitting: Caused by excessive tension during forming. Prevented by using proper tension settings and ensuring that the material is not overheated.

- Neckdowns: Caused by localized thinning of the material. Prevented by using proper forming tools and ensuring that the material is heated evenly.

4. How do you troubleshoot a tube building machine when it is not producing tubes to the desired specifications?

- Check the machine settings and ensure that they are correct for the material and tube dimensions being produced.

- Inspect the forming tools for wear or damage and replace them if necessary.

- Check the heating system and ensure that it is operating properly and providing the correct temperature.

- Inspect the material for defects and ensure that it is of the correct quality.

5. What are the safety precautions that need to be taken when operating a tube building machine?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Keep hands and clothing away from moving parts.

- Do not operate the machine if it is not properly guarded.

- Be aware of the potential for hot materials and take precautions to avoid burns.

6. What is the role of lubrication in the tube building process?

- Reduces friction between the forming tools and the material.

- Prevents galling and wear on the forming tools.

- Improves the surface finish of the tube.

7. What are the different types of tube building machines?

- Draw benches: Use a die to pull the tube through to reduce its diameter and increase its length.

- Tube welding machines: Use heat to join two edges of the metal strip to form a tube.

- Rotary tube mills: Use a series of rollers to form the tube from a flat strip of metal.

8. What are the advantages and disadvantages of using a draw bench versus a tube welding machine?

Draw bench

- Advantages: Can produce tubes with very precise dimensions, high strength, and a smooth surface finish.

- Disadvantages: Slower production rates than tube welding machines, limited to producing smaller diameter tubes.

Tube welding machine

- Advantages: Faster production rates than draw benches, can produce larger diameter tubes.

- Disadvantages: May produce tubes with less precise dimensions and a lower surface finish than draw benches.

9. What is the maintenance schedule for a tube building machine?

- Daily: Check for leaks, loose connections, and worn or damaged parts.

- Weekly: Lubricate moving parts, clean sensors, and inspect forming tools.

- Monthly: Perform a thorough inspection of the machine, including a check of the electrical system and hydraulics.

10. What are the quality control procedures that you would implement for a tube building machine?

- Inspect incoming materials for defects.

- Monitor the machine settings and make adjustments as needed.

- Inspect the finished tubes for dimensional accuracy, surface finish, and other quality requirements.

- Perform regular calibration and maintenance of the machine.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tube Building Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tube Building Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tube Building Machine Operator is responsible for operating and maintaining tube building machinery to produce high-quality tubes for various applications. They must work efficiently and follow established safety protocols to ensure a smooth and accident-free operation.

1. Machine Operation

The primary responsibility of a Tube Building Machine Operator is to operate and maintain tube building machinery. This involves:

- Setting up and calibrating the machine according to specifications

- Loading and unloading raw materials, such as metal strips or coils

- Monitoring the machine during operation and making necessary adjustments

2. Quality Control

Ensuring the quality of the produced tubes is crucial. The operator is responsible for:

- Inspecting the tubes for defects or inconsistencies

- Taking measurements and conducting tests to verify the tubes meet specifications

- Rejecting non-conforming tubes and reporting any quality issues

3. Maintenance and Troubleshooting

To ensure optimal performance, the operator must maintain and troubleshoot the machine. This includes:

- Performing routine maintenance tasks, such as cleaning and lubrication

- Identifying and resolving minor issues or malfunctions

- Reporting major issues or breakdowns to the supervisor for timely repairs

4. Safety and Compliance

Adhering to safety protocols and maintaining a clean and organized work area are essential. The operator is responsible for:

- Following all safety regulations and wearing appropriate protective gear

- Maintaining a clean and organized work area to prevent accidents

- Reporting any unsafe conditions or practices to the supervisor

Interview Tips

Preparing thoroughly for an interview is essential to showcase your skills and qualifications effectively. Here are some tips to help you ace the interview for a Tube Building Machine Operator position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. Learn about their products or services, industry standing, and company culture. Understanding the company’s needs and the role’s responsibilities will help you tailor your answers and demonstrate your interest in the opportunity.

2. Highlight Relevant Experience and Skills

Review the job description thoroughly and identify the key skills and experience required for the role. Prepare examples from your previous work experience that showcase your proficiency in operating and maintaining tube building machinery, conducting quality control checks, and troubleshooting common issues. Quantify your accomplishments and use specific metrics to demonstrate your impact.

3. Practice Common Interview Questions

Anticipate common interview questions related to your technical skills, problem-solving abilities, and safety practices. Practice answering these questions clearly and concisely, providing specific examples from your experience. This will help you articulate your qualifications confidently and leave a lasting impression on the interviewers.

4. Prepare Questions for the Interviewers

Asking thoughtful questions during the interview shows you are engaged and interested in the position. Prepare questions about the company’s growth plans, the team you will be working with, and opportunities for professional development. This demonstrates your enthusiasm and eagerness to contribute to the organization’s success.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. Show respect for the interviewers and the company by presenting yourself in a clean and well-groomed manner. Punctuality reflects your reliability and commitment to the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tube Building Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tube Building Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.