Are you gearing up for a career in Valve Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Valve Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

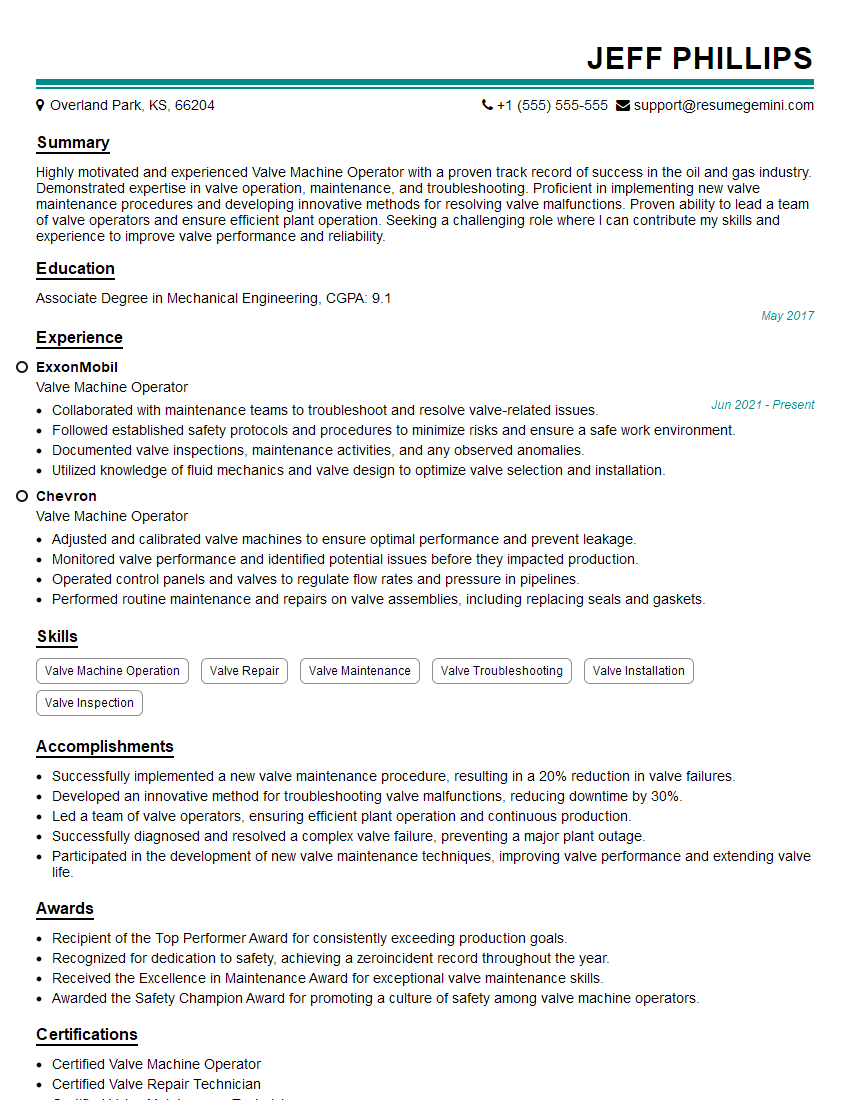

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valve Machine Operator

1. Describe the different types of valves you have operated in the past.

- Gate valves: Used to completely shut off the flow of a fluid.

- Globe valves: Used to regulate the flow of a fluid.

- Check valves: Used to prevent the flow of a fluid in one direction.

- Ball valves: Used to shut off the flow of a fluid quickly and easily.

- Butterfly valves: Used to regulate the flow of a fluid in a large diameter pipe.

2. What are the key responsibilities of a Valve Machine Operator?

- Operate valves to control the flow of fluids in a process system.

- Monitor and maintain valves to ensure proper operation.

- Follow written procedures and instructions to ensure the safe and efficient operation of the valve system.

- Troubleshoot valve problems and take corrective action.

- Maintain a clean and organized work area.

3. Describe the different types of valve actuators.

- Manual actuators: Operated by hand.

- Electric actuators: Operated by electricity.

- Hydraulic actuators: Operated by hydraulic pressure.

- Pneumatic actuators: Operated by air pressure.

4. What is the importance of valve maintenance?

- Prevent valve failures and leaks.

- Ensure the safe and efficient operation of the valve system.

- Extend the life of valves.

- Reduce downtime and maintenance costs.

5. Describe the different types of valve maintenance procedures

- Preventive maintenance: Performed on a regular basis to prevent valve failures.

- Corrective maintenance: Performed to repair or replace valves that have failed.

- Emergency maintenance: Performed to repair or replace valves that have failed in a critical situation.

6. What are the safety precautions that must be taken when working with valves?

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

- Be aware of the potential hazards of the fluids being handled.

- Use proper tools and equipment.

- Never work on a valve that is under pressure.

7. What is the difference between a valve and a valve operator?

- A valve is a mechanical device that controls the flow of a fluid.

- A valve operator is a device that is used to open or close a valve.

8. What are the different types of valve position indicators?

- Visual indicators: Show the position of the valve by means of a pointer or indicator.

- Electrical indicators: Send a signal to a remote location to indicate the position of the valve.

- Pneumatic indicators: Send a signal to a remote location to indicate the position of the valve.

9. What are the different types of valve packing?

- Graphite packing: Used for high-temperature applications.

- Teflon packing: Used for low-temperature applications.

- Rubber packing: Used for general purpose applications.

- Metallic packing: Used for high-pressure applications.

10. What are the different types of valve flanges?

- Raised face flanges: Used for high-pressure applications.

- Flat face flanges: Used for low-pressure applications.

- Ring type joint flanges: Used for high-pressure and high-temperature applications.

- Slip-on flanges: Used for low-pressure applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valve Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valve Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Valve Machine Operator

A Valve Machine Operator plays a crucial role in the manufacturing sector, responsible for operating and maintaining machinery used to produce valves. Their primary duties include:

1. Valve Manufacturing and Maintenance

Valve Machine Operators are responsible for operating and maintaining machinery used to create and assemble valves. They ensure that machines are calibrated and adjusted correctly to produce valves that meet specifications.

- Setting up and operating CNC machines, lathes, and other valve-making equipment.

- Inspecting and testing finished valves to ensure they meet quality standards.

- Troubleshooting and repairing machines to minimize downtime.

2. Production Monitoring

These operators monitor the production process closely to ensure efficiency and quality. They make adjustments to machines and processes as needed to optimize production and minimize waste.

- Monitoring machine performance and making adjustments to maintain productivity.

- Identifying and resolving production issues promptly.

- Documenting production data for record-keeping and analysis.

3. Safety and Compliance

Valve Machine Operators prioritize safety and compliance in the workplace. They follow established safety procedures and regulations to prevent accidents and maintain a safe work environment.

- Adhering to safety protocols and wearing appropriate protective gear.

- Maintaining a clean and organized work area.

- Reporting any safety hazards or concerns.

4. Teamwork and Communication

Operators collaborate with team members, including engineers, quality control inspectors, and supervisors. They communicate effectively to ensure smooth production and resolve issues promptly.

- Working effectively with colleagues in a team environment.

- Communicating clearly and concisely with other departments.

- Providing feedback and suggestions for process improvements.

Interview Preparation Tips for Valve Machine Operators

To ace an interview for a Valve Machine Operator position, candidates can follow these preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s profile, industry, and the specific role you are applying for. This knowledge will help you align your qualifications with the company’s needs and tailor your responses to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry news and trade publications.

- Study the job description thoroughly.

2. Practice your Answers

Anticipate common interview questions and prepare concise and well-structured responses. Practice answering questions that highlight your skills, experience, and knowledge of the industry. Use the STAR method (Situation, Task, Action, Result) to provide specific examples.

3. Showcase your Technical Skills

As a Valve Machine Operator, you must demonstrate your technical proficiency. Highlight your knowledge of CNC machines, lathe operations, and valve manufacturing processes. Consider obtaining certifications or training to enhance your credibility.

- Obtain a CNC operator certification.

- Complete a valve manufacturing training program.

- Build a portfolio of your previous work.

4. Emphasize Safety and Compliance

Safety is paramount in industrial settings. Emphasize your commitment to safety and compliance. Explain how you prioritize safety in your work and ensure compliance with established regulations and procedures.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that explore the company’s culture, growth opportunities, and specific aspects of the role that interest you.

- Inquire about the company’s commitment to employee development.

- Ask about the company’s plans for future growth and innovation.

- Seek clarification on specific responsibilities and expectations of the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Valve Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.