Feeling lost in a sea of interview questions? Landed that dream interview for Valve Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Valve Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

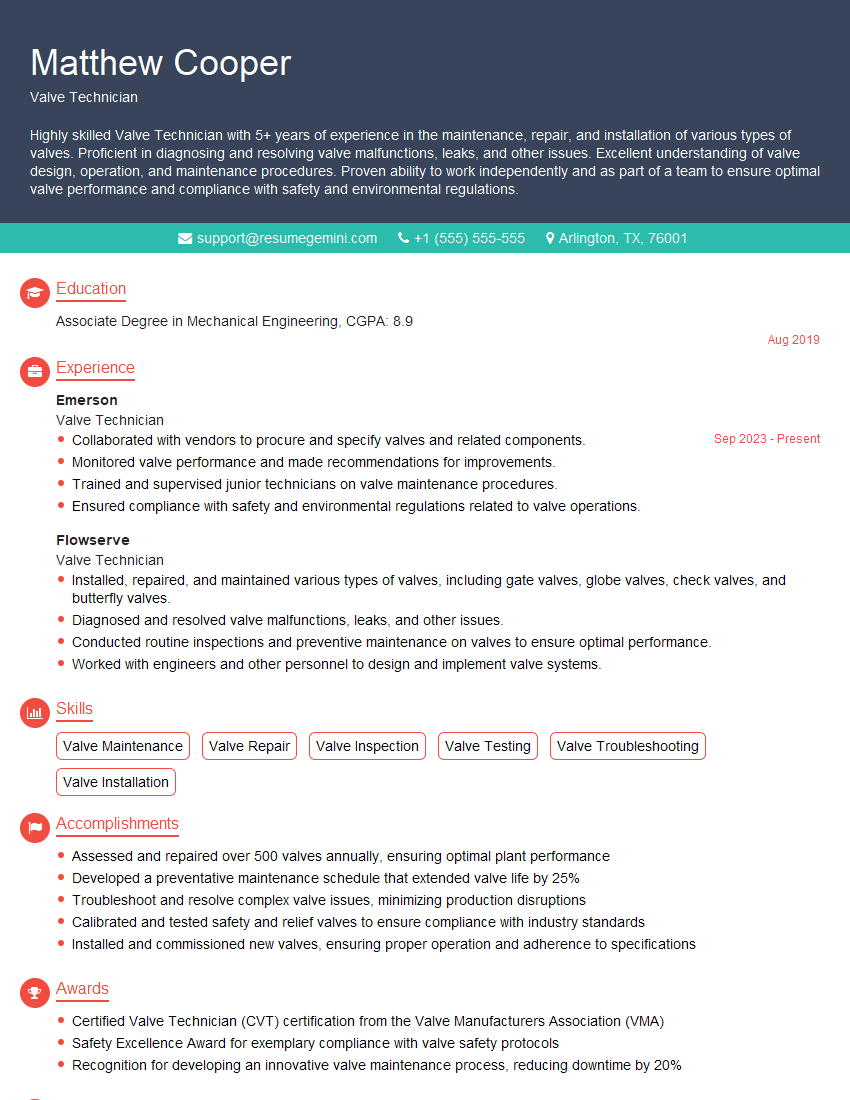

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Valve Technician

1. Describe the different types of valves and their applications?

As a Valve Technician, I have extensive knowledge of various valve types and their specific applications:

- Gate Valves: Linear motion valves used for isolating or throttling flow, found in pipelines, power plants, and water treatment facilities.

- Globe Valves: Stop and regulate flow with a movable disc or plug, commonly used in plumbing, heating systems, and chemical processing.

- Ball Valves: Quarter-turn valves with a rotating ball to control flow, employed in gas lines, oil pipelines, and industrial processes.

- Butterfly Valves: Rotary valves with a disc that rotates to regulate flow, suitable for large-diameter applications such as water supply andHVAC.

- Check Valves: Allow flow in one direction only, preventing backflow, used in pumps, pipelines, and irrigation systems.

2. Explain the maintenance procedures for different types of valves?

Inspection and Cleaning

- Inspect valve components for wear and damage.

- Clean valves regularly to remove debris and ensure smooth operation.

Lubrication

- Lubricate moving parts to reduce friction and wear.

- Select the appropriate lubricant based on valve type and operating conditions.

Repair and Replacement

- Repair or replace worn components to restore valve functionality.

- Follow manufacturer’s guidelines for valve repair and replacement.

Testing

- Test valves after maintenance to ensure proper operation.

- Conduct pressure tests, flow tests, and leakage tests.

3. How do you troubleshoot common valve problems?

Troubleshooting common valve problems involves a systematic approach:

- Identify Symptoms: Observe abnormal behavior, such as leaks, pressure drops, or flow restrictions.

- Inspect Valve: Check for visible damage, wear, or debris.

- Examine Operating Conditions: Verify that valve is operating within its specified parameters.

- Test Valve: Conduct diagnostic tests to isolate the issue.

- Repair or Replace: Based on diagnosis, repair or replace faulty components.

4. What safety precautions should be taken when working with valves?

Safety is paramount when handling valves:

- PPE: Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and coveralls.

- Lockout/Tagout: Ensure valves are properly locked out and tagged before performing maintenance.

- Isolation: Close valves and isolate them from the process before working on them.

- Pressure Release: Vent or bleed pressure from valves before disassembly.

- Avoid Hazardous Substances: Be aware of potential exposure to hazardous chemicals or fluids.

5. How do you stay updated on the latest valve technologies?

To stay current with valve advancements, I engage in continuous learning and professional development:

- Industry Conferences: Attend industry conferences and seminars to learn about new technologies and best practices.

- Technical Publications: Read trade magazines, journals, and whitepapers to stay informed about the latest valve developments.

- Product Training: Participate in training programs offered by valve manufacturers to learn about their new products and applications.

- Online Resources: Utilize online resources, such as industry forums and technical websites, to access up-to-date information.

6. Describe your experience with valve sizing and selection?

Valve sizing and selection is crucial for efficient and reliable operation:

- Flow Rate Calculations: Determine the required flow rate based on system design and operating conditions.

- Valve Sizing: Use equations and sizing software to calculate the appropriate valve size to meet flow requirements.

- Material Selection: Consider the corrosive and abrasive nature of the fluid, as well as operating temperature and pressure, to select the appropriate valve material.

- Performance Evaluation: Analyze valve performance parameters, such as pressure drop, flow capacity, and cavitation potential, to ensure optimal operation.

7. Explain the importance of proper valve installation and commissioning?

Proper valve installation and commissioning ensure safe and reliable operation:

- Installation: Follow manufacturer’s instructions for proper valve orientation, alignment, and support.

- Testing: Conduct pressure and leakage tests to verify valve integrity after installation.

- Commissioning: Gradually bring the valve into operation, monitoring performance and making necessary adjustments.

8. Describe your experience in valve maintenance and repair?

Effective valve maintenance and repair are essential for continued operability:

- Preventive Maintenance: Perform regular inspections, cleaning, lubrication, and adjustments to prevent failures.

- Troubleshooting: Diagnose and repair common valve problems, such as leaks, wear, and sticking.

- Overhaul: Dismantle, inspect, and replace worn components to restore valve functionality.

9. Explain the role of valves in process control systems?

Valves play a critical role in process control systems:

- Flow Control: Valves regulate the flow of fluids and gases in pipelines, optimizing process parameters.

- Isolation: Valves isolate sections of the process system for maintenance or emergencies.

- Pressure Control: Valves maintain desired pressures by regulating flow and preventing overpressurization.

- Safety: Valves provide protection against dangerous conditions, such as overpressure, backflow, and uncontrolled fluid release.

10. Describe your experience in valve automation and instrumentation?

Automation and instrumentation enhance valve functionality and system efficiency:

- Valve Actuators: Install and configure valve actuators to automate valve operation based on process signals.

- Instrumentation: Integrate sensors and instruments with valves to monitor and control flow, pressure, and temperature.

- SCADA Systems: Interface valves with SCADA systems to provide real-time monitoring and remote control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Valve Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Valve Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Valve Technicians are responsible for installing, maintaining, and repairing valves in various industrial settings. Key job responsibilities include:

1. Valve Selection and Installation

Reviewing engineering drawings and specifications to determine appropriate valve types and sizes for specific applications.

- Selecting and procuring valves from reputable suppliers.

- Installing valves according to established procedures and industry standards.

2. Valve Maintenance and Repair

Performing regular inspections of valves to identify potential issues or signs of wear and tear.

- Disassembling and repairing valves as needed, replacing worn or damaged parts.

- Conducting leak tests and pressure tests to ensure proper operation.

3. Troubleshooting and Problem Solving

Identifying and resolving valve-related issues, such as leaks, blockages, or performance problems.

- Analyzing system data and using diagnostic tools to determine root causes.

- Developing and implementing repair procedures to address specific problems.

4. Process Optimization

Working with engineers and operators to optimize valve selection and maintenance strategies.

- Identifying areas for improvement in valve performance or efficiency.

- Implementing best practices and recommending upgrades or modifications.

Interview Tips

To ace a Valve Technician interview, it is crucial to prepare thoroughly and showcase your skills and experience. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and industry standing. Research the specific job requirements and responsibilities to ensure a clear understanding of the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical expertise in valve selection, installation, maintenance, and repair. Provide specific examples of projects or situations where you have demonstrated these skills.

3. Showcase Problem-Solving Abilities

Interviewers are interested in candidates who can think critically and solve problems effectively. Share examples of challenges you have faced and the steps you took to resolve them.

4. Demonstrate Attention to Detail

Valve Technicians need to be highly attentive to detail. Highlight your ability to carefully follow instructions, perform precise measurements, and adhere to safety protocols.

5. Prepare Questions to Ask

Asking informed questions at the end of the interview shows your interest in the role and the company. Prepare questions about specific aspects of the job, the company culture, or the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Valve Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!