Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Varnishing Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

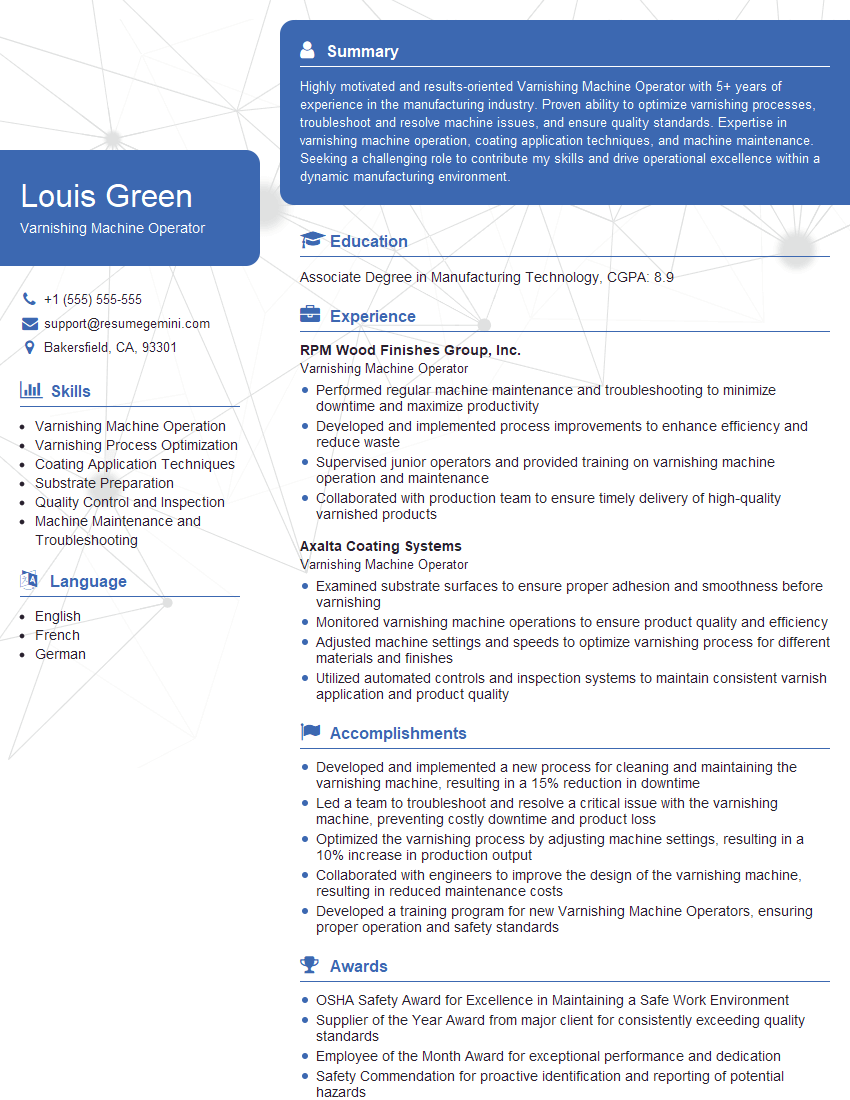

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Varnishing Machine Operator

1. What are the key responsibilities of a Varnishing Machine Operator?

- Monitor and operate varnishing machines to apply a protective or decorative coating to various surfaces.

- Adjust machine settings, such as speed, temperature, and roller pressure, to ensure proper application of the varnish.

- Load and unload materials, including sheets, rolls, or individual pieces, into the machine.

- Inspect coated materials for defects or inconsistencies and make necessary adjustments to the machine or process.

- Maintain the machine and its components by cleaning, lubricating, and performing minor repairs.

2. Describe the different types of varnishes used in the industry and their applications.

Solvent-based varnishes

- These varnishes contain organic solvents that evaporate during the drying process, leaving behind a protective film.

- They are often used for their durability and high gloss finish, and are suitable for a wide range of materials, including wood, metal, and plastic.

Water-based varnishes

- These varnishes use water as the solvent, making them more environmentally friendly than solvent-based varnishes.

- They dry more slowly than solvent-based varnishes and may require multiple coats to achieve the desired finish.

Ultraviolet (UV) curable varnishes

- These varnishes are cured using ultraviolet light, which initiates a chemical reaction that hardens the varnish.

- They offer fast drying times and a durable finish, but require specialized equipment and can be more expensive than other types of varnishes.

3. What are the key factors to consider when selecting the appropriate varnish for a particular application?

- The material to be coated

- The desired finish (e.g., gloss, matte, satin)

- The durability and protection required

- The environmental conditions

- The cost and availability

4. What are the safety precautions that must be taken when operating a varnishing machine?

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator when necessary.

- Ensure the machine is properly grounded and maintained.

- Handle varnishes and solvents carefully, as they may be flammable or toxic.

- Follow all safety instructions and guidelines provided by the machine manufacturer and the varnish supplier.

5. How do you troubleshoot common problems that may arise while operating a varnishing machine?

- Uneven coating: Check the machine settings, such as speed, temperature, and roller pressure, and adjust accordingly.

- Bubbles or streaks: Ensure the varnish is properly mixed and free of contaminants. Clean the rollers and nozzles regularly.

- Poor adhesion: Check the surface preparation and ensure the material is compatible with the varnish. Apply a primer if necessary.

- Slow drying: Check the temperature and humidity. Increase the temperature or use a faster-drying varnish.

6. What is the importance of maintaining and calibrating the varnishing machine?

- Ensures consistent and high-quality output.

- Prevents breakdowns and costly repairs.

- Extends the lifespan of the machine.

- Meets safety and regulatory requirements.

7. Describe your experience with different types of varnishing machines, including their capabilities and limitations.

I have experience operating various types of varnishing machines, including flatbed, rotary, and curtain coaters. Flatbed machines are suitable for small, flat surfaces, while rotary machines are ideal for cylindrical or continuous materials. Curtain coaters are used for high-volume applications and can provide a uniform coating on complex shapes.

8. How do you ensure the quality of the finished product?

- Inspect the material before and after varnishing for defects or inconsistencies.

- Monitor the machine’s performance and make adjustments as needed.

- Use proper curing and drying techniques to ensure a durable finish.

9. What are your strengths and weaknesses as a Varnishing Machine Operator?

Strengths

- Excellent attention to detail and precision.

- Strong troubleshooting skills.

- Experience with different types of varnishing machines.

- Knowledge of various varnishes and their applications.

Weaknesses

- Limited experience with UV curable varnishes.

- Could improve time management skills.

10. Why are you interested in this Varnishing Machine Operator position, and why do you think you are the best candidate?

I am eager to join your company as a Varnishing Machine Operator because I am passionate about the manufacturing process and delivering high-quality products. My experience in operating different types of varnishing machines, combined with my attention to detail and troubleshooting skills, make me a valuable asset to your team. I am confident that I can use my knowledge and expertise to contribute to the success of your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Varnishing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Varnishing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Varnishing Machine Operator plays a vital role in ensuring the smooth operation and quality output of a varnishing machine. The primary responsibilities of a Varnishing Machine Operator include:

1. Operation and Maintenance of Varnishing Machine

Operate and maintain the varnishing machine following established procedures and safety guidelines.

- Set up the machine according to specifications, ensuring proper varnish flow and consistency.

- Monitor machine performance and make necessary adjustments to maintain optimal varnishing quality.

2. Varnishing Process

Apply varnish to various materials, including paper, wood, metal, and plastics, as per the production requirements.

- Load and unload materials onto the machine conveyor system.

- Control varnish application thickness, speed, and temperature to achieve desired results.

3. Quality Control and Inspection

Inspect varnished surfaces for defects, ensuring adherence to quality standards.

- Check for proper varnish coverage, smoothness, and adherence.

- Identify and resolve any quality issues promptly.

4. Equipment Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting of the varnishing machine to ensure its optimal performance.

- Clean and lubricate machine components regularly.

- Identify and resolve minor machine malfunctions.

Interview Tips

Preparing well for a Varnishing Machine Operator interview is crucial to showcasing your skills and increasing your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s industry, products or services, and the specific responsibilities of the Varnishing Machine Operator role. This knowledge will enable you to answer questions intelligently and demonstrate your interest in the position.

- Visit the company’s website, social media pages, and industry-related news sources.

- Read the job description carefully to understand the exact requirements of the role.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience that align with the job responsibilities. This includes your technical knowledge of varnishing machines, quality control experience, and any previous experience in a manufacturing or production setting.

- Provide specific examples of your work that demonstrate your abilities.

- Quantify your accomplishments whenever possible to showcase your impact.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and the industry. Practice answering these questions confidently and concisely, using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Some common interview questions include: “Tell me about your experience operating varnishing machines,” “How do you ensure quality in your work?” and “What are your strengths and weaknesses as a Varnishing Machine Operator?”

- Consider potential questions specific to the company and the role.

4. Demonstrate Enthusiasm and Professionalism

Throughout the interview, maintain a positive attitude and show enthusiasm for the role and the company. Dress professionally, arrive on time, and be respectful to the interviewers. Ask thoughtful questions about the company and the position to indicate your interest and engagement.

- Be prepared to share examples of your problem-solving abilities and teamwork skills.

- Convey your commitment to safety and quality in your work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Varnishing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.