Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Warp Coiler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Warp Coiler so you can tailor your answers to impress potential employers.

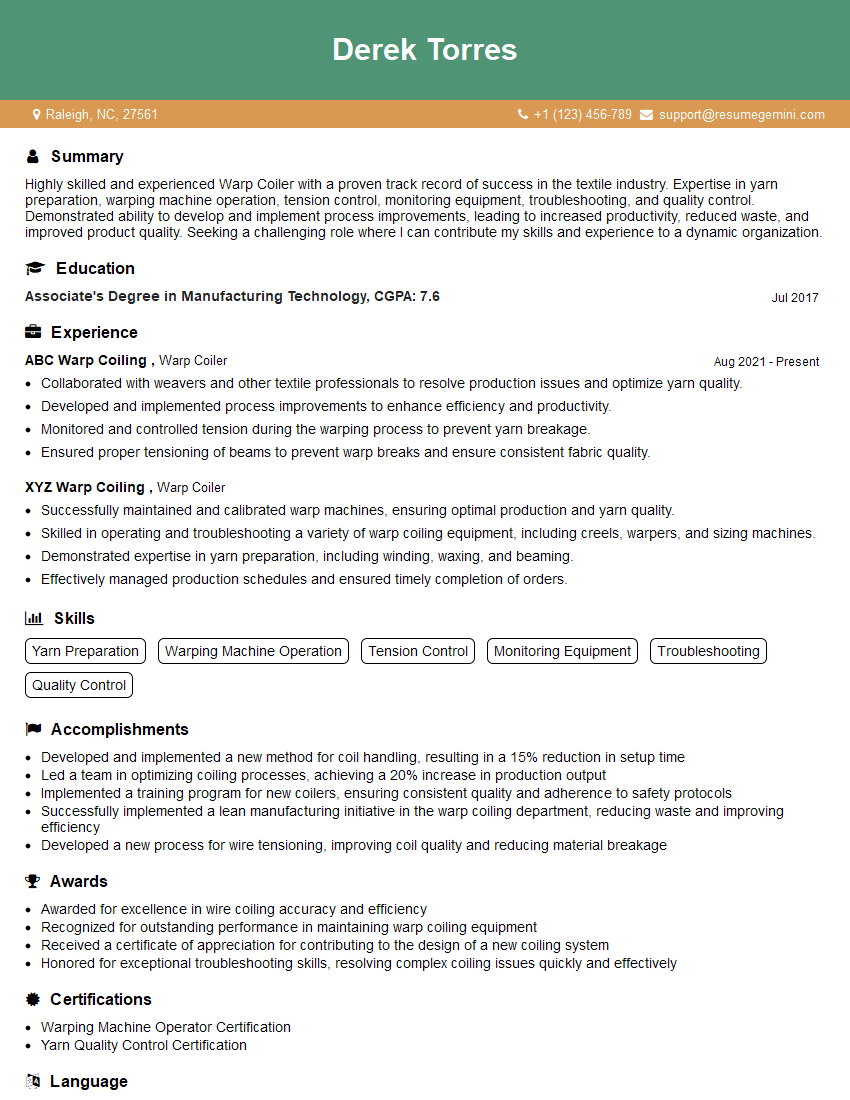

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warp Coiler

1. How do you ensure the correct tension of the warp yarn during the warping process?

To ensure the correct tension of the warp yarn during the warping process, I follow these steps:

- Calibrate the tensioner according to the yarn type and count.

- Monitor the tension throughout the warping process using a tension meter.

- Adjust the tension as needed to maintain the desired tension range.

- Inspect the warped yarn regularly for any variations in tension.

2. Describe the different types of warping machines and their applications

Sectional Warping Machine

- Used for producing warps for narrow fabrics, such as ribbons and tapes.

- Winds the yarn onto a sectional beam, which is divided into several sections.

Beam Warping Machine

- Used for producing warps for wide fabrics, such as carpets and curtains.

- Winds the yarn onto a single large beam.

3. How do you handle and store the warped yarn to prevent damage?

To prevent damage to the warped yarn, I follow these practices:

- Handle the yarn carefully to avoid snagging or breaking.

- Store the yarn in a cool, dry, and dust-free environment.

- Protect the yarn from moisture and sunlight.

- Cover or wrap the yarn to keep it clean and protected.

4. What are the common defects that can occur during warping, and how do you troubleshoot them?

Tension variations

- Causes: Incorrect tension settings, mechanical issues.

- Troubleshooting: Recalibrate tension, inspect for mechanical issues.

Yarn breaks

- Causes: Weak or damaged yarn, improper threading.

- Troubleshooting: Inspect yarn quality, check threading path.

5. Describe the quality control checks performed during the warping process

- Yarn tension

- Yarn spacing

- Beam condition

- Yarn breaks

- Warp width

6. How do you calculate the yarn requirement for a given warp length and width?

Yarn requirement (in meters) = Warp length (in meters) x Number of ends x Yarn count (in Tex)

7. What are the safety considerations when operating a warping machine?

- Wear appropriate safety gear.

- Keep hands away from moving parts.

- Avoid loose clothing that could get caught.

- Be aware of potential tripping hazards.

- Follow proper lockout procedures before performing maintenance.

8. Describe the maintenance procedures you perform on a warping machine

- Regular cleaning and inspection.

- Lubrication of moving parts.

- Calibration of tensioner and other sensors.

- Replacement of worn or damaged parts.

- Regular maintenance schedule to ensure optimal performance.

9. How do you stay updated on the latest developments in warping technology?

- Attend industry conferences and seminars.

- Read technical articles and journals.

- Consult with machinery manufacturers.

- Seek training opportunities to improve skills.

10. Describe a challenging situation you faced while operating a warping machine and how you resolved it

Once, I encountered a situation where the yarn kept breaking during the warping process. After inspecting the yarn and machinery, I identified that the tension was too high. I recalibrated the tensioner to the appropriate setting, and the problem was resolved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warp Coiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warp Coiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Warp Coilers play a vital role in the textile industry by preparing warp beams for weaving. Their key responsibilities include:

1. Machine Operation and Maintenance

Operate warp coiling machines to wind yarn onto beams, ensuring proper tension, density, and alignment.

- Monitor machine performance, identify and troubleshoot any malfunctions.

- Perform regular maintenance tasks, such as cleaning, lubrication, and adjustments.

2. Production Management

Plan and schedule production runs, ensuring efficient operation and meeting delivery deadlines.

- Monitor production output and identify areas for improvement.

- Work closely with other departments to coordinate production and ensure seamless workflow.

3. Quality Control

Inspect wound beams for defects and ensure compliance with quality standards.

- Identify and correct any flaws in yarn winding or beam preparation.

- Maintain accurate records of production and quality control.

4. Safety and Compliance

Comply with all safety regulations and wear appropriate protective gear.

- Follow established procedures for handling and storing materials.

- Stay up-to-date on industry best practices and implement them in the workplace.

Interview Tips

Preparing adequately for an interview can significantly increase your chances of success. Here are some tips to help you ace your Warp Coiler interview:

1. Research the Company and Role

Gather information about Warp Coiler and the specific role you are applying for. This will demonstrate your interest and enthusiasm.

- Visit the company website to learn about their mission, values, and products.

- Read industry news and articles to stay abreast of current trends in warp coiling.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements.

- Provide specific examples of your ability to operate warp coiling machines efficiently.

- Quantify your achievements, such as increasing production output or reducing defect rates.

3. Prepare Questions

Asking well-thought-out questions during the interview shows that you are engaged and interested in the role.

- Inquire about the company’s growth plans and industry outlook.

- Ask about training and development opportunities for employees.

4. Dress Professionally and Arrive Punctually

First impressions matter, so make sure to dress professionally and arrive for the interview on time.

- Wear business attire or clothing appropriate for the textile industry.

- Allow ample time for travel to ensure you are not rushed or stressed.

5. Follow Up

After the interview, send a thank-you note to the interviewer. This is an opportunity to reiterate your interest and highlight any additional qualifications.

- Express your gratitude for the opportunity to interview.

- Reiterate your key qualifications and how they align with the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warp Coiler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!