Feeling lost in a sea of interview questions? Landed that dream interview for Warp Tension Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Warp Tension Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

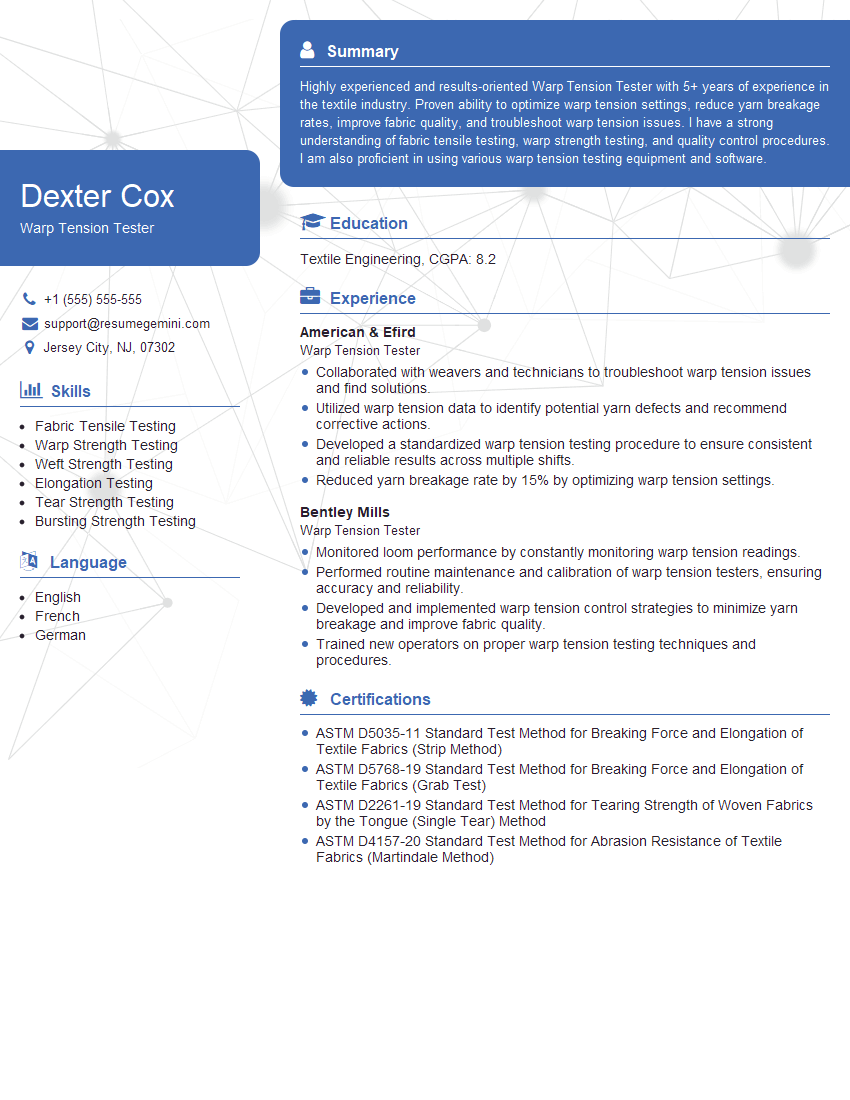

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warp Tension Tester

1. What is a Warp Tension Tester, and what are its key functions?

A Warp Tension Tester is a device used to measure the tension in the warp yarns of a fabric. It is used to ensure that the warp yarns are at the correct tension to produce a fabric with the desired quality and properties.

- Warp tension testers are typically used in the production of woven fabrics.

- They can be used to measure the tension of warp yarns before, during, and after the weaving process.

- The data collected from a warp tension tester can be used to adjust the weaving process and ensure that the fabric is produced with the desired quality and properties.

2. Describe the different types of Warp Tension Testers and their applications.

Mechanical Warp Tension Testers

- Mechanical warp tension testers are the most basic type of warp tension tester.

- They use a mechanical balance to measure the tension in the warp yarns.

- Mechanical warp tension testers are relatively inexpensive and easy to use.

- However, they are not as accurate as other types of warp tension testers.

Electronic Warp Tension Testers

- Electronic warp tension testers use a load cell to measure the tension in the warp yarns.

- Electronic warp tension testers are more accurate than mechanical warp tension testers.

- They also offer a wider range of features, such as data logging and statistical analysis.

- Electronic warp tension testers are more expensive than mechanical warp tension testers.

Non-Contact Warp Tension Testers

- Non-contact warp tension testers use a laser or other non-contact sensor to measure the tension in the warp yarns.

- Non-contact warp tension testers are the most accurate type of warp tension tester.

- They are also the most expensive type of warp tension tester.

3. How do you calibrate a Warp Tension Tester?

The calibration of a warp tension tester is a critical step to ensure that the tester is providing accurate measurements. The calibration process typically involves the following steps:

- Hanging a known weight from the warp tension tester.

- Adjusting the tester until the displayed tension reading matches the known weight.

- Repeating steps 1 and 2 for a range of weights.

- Once the tester is calibrated, it should be checked regularly to ensure that it is still providing accurate measurements.

4. What are the common problems that can occur with Warp Tension Testers, and how do you troubleshoot them?

There are a number of common problems that can occur with warp tension testers, including:

- Inaccurate readings

- Mechanical problems

- Electrical problems

To troubleshoot these problems, you can follow these steps:

- Check the calibration of the tester.

- Inspect the tester for any mechanical problems, such as loose or damaged parts.

- Check the electrical connections to the tester.

- If you are unable to troubleshoot the problem yourself, you can contact the manufacturer of the tester for assistance.

5. What are the latest advancements in Warp Tension Testing technology?

The latest advancements in warp tension testing technology include:

- The development of non-contact warp tension testers.

- The use of digital signal processing to improve the accuracy and reliability of warp tension measurements.

- The development of new software that makes it easier to analyze warp tension data.

6. What are the different factors that can affect the tension of warp yarns in a fabric?

The tension of warp yarns in a fabric can be affected by a number of factors, including:

- The type of fabric being woven.

- The density of the fabric.

- The speed of the weaving process.

- The tension of the weft yarns.

- The environmental conditions in the weaving room.

7. How can you use a Warp Tension Tester to improve the quality of a fabric?

By using a warp tension tester to monitor the tension of warp yarns in a fabric, you can:

- Ensure that the warp yarns are at the correct tension to produce a fabric with the desired quality and properties.

- Identify and correct problems with the weaving process that can lead to defects in the fabric.

- Improve the efficiency of the weaving process by reducing the amount of waste and rework.

8. What are the safety precautions that should be taken when using a Warp Tension Tester?

When using a warp tension tester, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as safety glasses and gloves.

- Do not use the tester in a hazardous environment.

- Do not touch the moving parts of the tester.

- Follow the manufacturer’s instructions for use and maintenance.

9. What are the different maintenance procedures that should be performed on a Warp Tension Tester?

The maintenance procedures that should be performed on a warp tension tester include:

- Regularly cleaning the tester.

- Periodically calibrating the tester.

- Inspecting the tester for any signs of damage.

- Following the manufacturer’s instructions for maintenance.

10. How do you dispose of a Warp Tension Tester?

When disposing of a warp tension tester, it is important to follow the manufacturer’s instructions.

- The tester should be disposed of in accordance with local environmental regulations.

- The tester should be dismantled and the components recycled or disposed of properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warp Tension Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warp Tension Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Warp Tension Tester is a highly skilled professional responsible for testing the tension of warp yarns in textile production. The key job responsibilities include:

1. Testing Warp Yarn Tension

Using specialized equipment, they measure and record the force required to pull the warp yarns in a woven fabric.

- Adheres to established procedures and industry standards.

- Maintains accurate records of test results.

2. Analysing Test Data

After testing, they analyze the data to identify any variations or irregularities in the warp tension.

- Compares results to specifications and identifies deviations.

- Investigates causes of tension variations and recommends solutions.

3. Maintaining Test Equipment

They ensure that the testing equipment is properly calibrated and maintained to ensure accuracy and reliability.

- Performs regular maintenance and repairs as needed.

- Monitors and adjusts equipment settings to achieve optimal performance.

4. Troubleshooting and Problem-Solving

In case of unexpected results or equipment malfunctions, they troubleshoot and diagnose the issue efficiently.

- Identifies and resolves problems quickly to minimize production downtime.

- Collaborates with other team members to find solutions.

Interview Tips

To ace the interview for a Warp Tension Tester position, it’s crucial to:

1. Research the Company and Industry

Learn about the company’s history, products/services, and industry trends. This shows interest and preparedness.

- Visit the company’s website and social media pages.

- Read industry publications and attend relevant events.

2. Highlight Relevant Skills and Experience

Showcase your technical proficiency in testing warp tension, data analysis, and troubleshooting.

- Quantify your experience with specific examples of how you improved warp tension quality.

- Emphasize your attention to detail and problem-solving abilities.

3. Prepare for Technical Questions

Be prepared to answer questions about testing procedures, equipment calibration, and troubleshooting techniques.

- Review industry standards and best practices.

- Practice describing your approach to problem-solving.

4. Show Enthusiasm and a Willingness to Learn

Express your passion for textile testing and your desire to continuously develop your skills.

- Highlight any coursework or certifications you have pursued.

- Inquire about opportunities for professional development within the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Warp Tension Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Warp Tension Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.