Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Warp Tying Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Warp Tying Machine Tender so you can tailor your answers to impress potential employers.

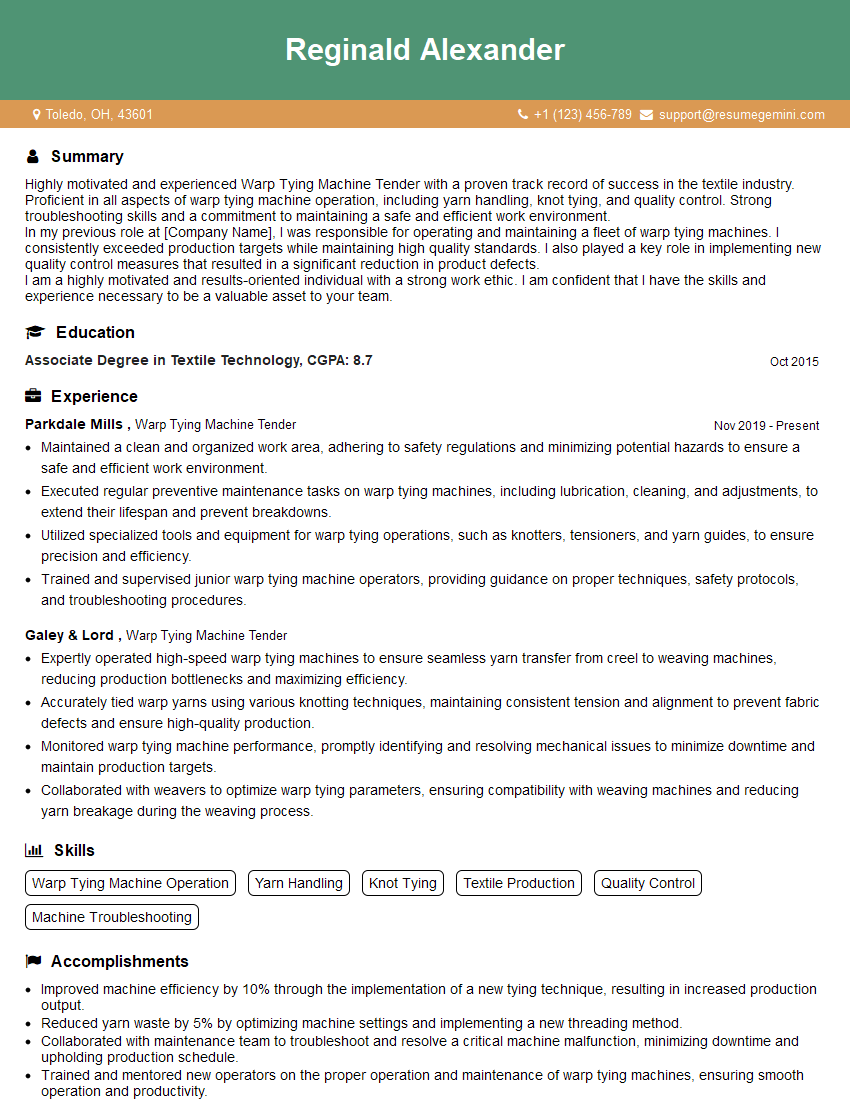

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warp Tying Machine Tender

1. Briefly describe the process of tying knots in the warp threads?

- The warp threads are passed through the healds and reed.

- The tying machine then uses a hook to grab the warp threads and tie them together.

- The knots are tied in a specific pattern to create the desired fabric design.

2. What are the different types of knots that can be tied on a warp tying machine?

- Single knot: The most basic type of knot, which is simply a loop tied around the warp threads.

- Double knot: A more secure type of knot, which is made by tying a single knot and then tying another knot around the first knot.

- Half-hitch: A type of knot that is used to tie the warp threads to the lease rods.

3. What are the factors that affect the quality of the knots?

- The type of knot being tied

- The tension of the warp threads

- The speed of the tying machine

- The condition of the tying machine

4. How do you troubleshoot a warp tying machine?

- First, check the machine for any obvious problems, such as loose wires or broken parts.

- If there are no obvious problems, then you can start to troubleshoot the machine by checking the following:

- The power supply

- The tension of the warp threads

- The speed of the tying machine

- The condition of the tying machine

- Once you have found the problem, you can then repair the machine and get it back up and running.

5. What are the safety precautions that must be taken when operating a warp tying machine?

- Always wear safety glasses when operating the machine.

- Keep your hands away from the moving parts of the machine.

- Do not operate the machine if it is not in good working condition.

- Follow all of the manufacturer’s instructions for operating the machine.

6. What are the different types of fabrics that can be produced on a warp tying machine?

- Plain weave fabrics

- Twill weave fabrics

- Satin weave fabrics

- Jacquard weave fabrics

7. What are the advantages of using a warp tying machine?

- Warp tying machines can produce high-quality knots that are consistent in size and shape.

- Warp tying machines can tie knots very quickly, which can save time and money.

- Warp tying machines are relatively easy to operate and maintain.

8. What are the disadvantages of using a warp tying machine?

- Warp tying machines can be expensive to purchase and maintain.

- Warp tying machines can be noisy and generate a lot of dust.

- Warp tying machines can be dangerous to operate if they are not used properly.

9. What is the difference between a warp tying machine and a warp drawing machine?

- Warp tying machines tie knots in the warp threads, while warp drawing machines draw the warp threads through the healds and reed.

- Warp tying machines are used to prepare the warp threads for weaving, while warp drawing machines are used to prepare the loom for weaving.

10. How do you maintain a warp tying machine?

- Clean the machine regularly to remove dust and debris.

- Oil the machine regularly to keep it running smoothly.

- Inspect the machine regularly for any signs of wear or damage.

- Calibrate the machine regularly to ensure that it is tying knots correctly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warp Tying Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warp Tying Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Warp Tying Machine Tender is responsible for operating and maintaining warp tying machines used in the textile industry. They ensure that the machines are running smoothly and efficiently, producing high-quality tied warps.

1. Machine Operation and Maintenance

The key responsibility of a Warp Tying Machine Tender is to operate and maintain the warp tying machines. This involves:

- Setting up and operating the machines according to established procedures

- Monitoring the machines during operation, checking for any issues or malfunctions

- Performing routine maintenance tasks, such as cleaning, lubricating, and adjusting the machines

- Troubleshooting and resolving any problems that may arise during operation

2. Quality Control

Warp Tying Machine Tenders are also responsible for ensuring the quality of the tied warps. This involves:

- Inspecting the tied warps for any defects or errors

- Making adjustments to the machines or processes to improve the quality of the tied warps

- Maintaining records of the quality of the tied warps

3. Safety and Housekeeping

Warp Tying Machine Tenders must also follow safety protocols and maintain a clean and organized work area. This involves:

- Wearing appropriate safety gear, such as gloves and safety glasses

- Following lockout/tagout procedures

- Keeping the work area clean and free of debris

4. Communication and Teamwork

Warp Tying Machine Tenders often work as part of a team and must communicate effectively with other team members. This involves:

- Communicating any issues or concerns to supervisors or team members

- Working with other team members to resolve problems

- Sharing knowledge and expertise with other team members

Interview Tips

To prepare for an interview for a Warp Tying Machine Tender position, candidates should focus on demonstrating their skills and experience in operating and maintaining warp tying machines, as well as their knowledge of quality control procedures and safety protocols. Here are some tips for acing the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can find this information on the company’s website, LinkedIn page, and other online resources.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. This includes your experience operating and maintaining warp tying machines, your knowledge of quality control procedures, and your safety record. You can also mention any other skills or experience that would be valuable to the company, such as your teamwork skills or your ability to work independently.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously. It is also a good way to get more information about the company and the position so that you can make an informed decision about whether or not the position is a good fit for you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warp Tying Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.