Are you gearing up for a career in Warp Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Warp Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

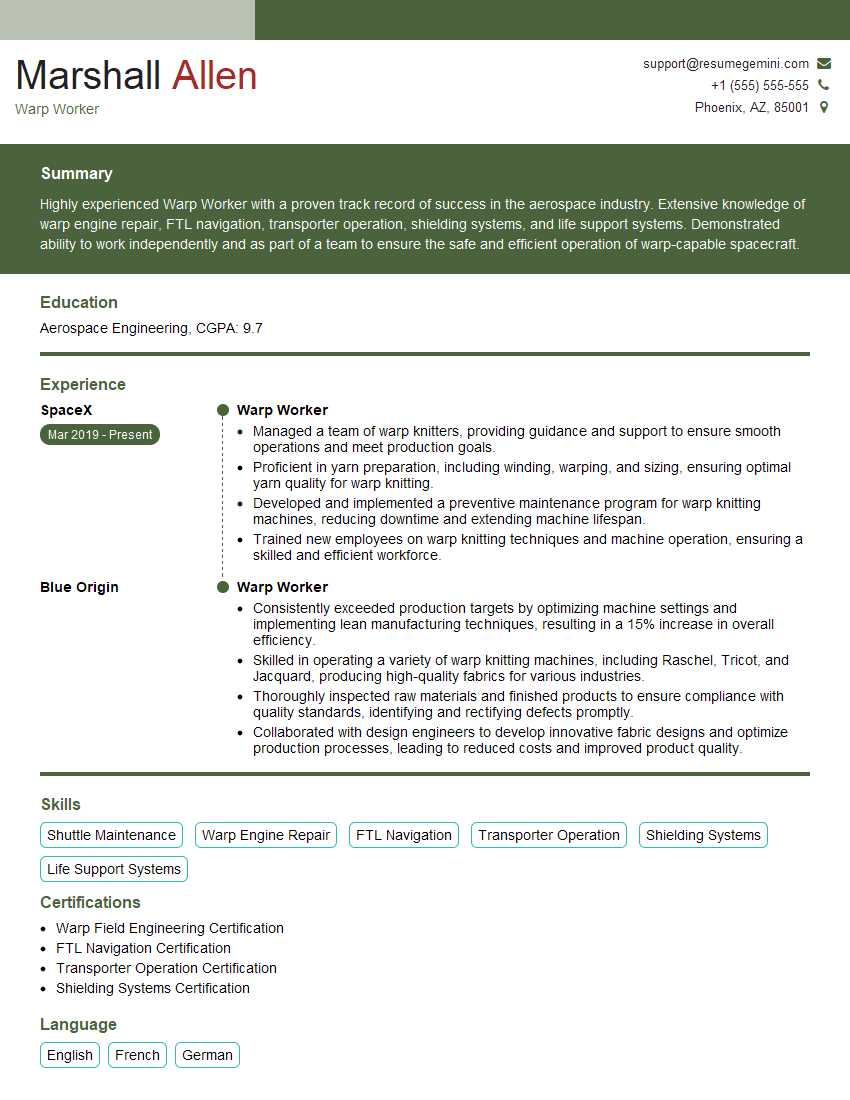

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warp Worker

1. Describe the main responsibilities of a Warp Worker?

- Operate and monitor warping machines to prepare yarn for weaving

- Inspect yarn for defects and make necessary adjustments to the machine

- Maintain and clean warping machines to ensure optimal performance

- Repair minor mechanical or electrical issues with warping machines

- Follow safety protocols and wear appropriate protective gear

2. Explain the different types of warping machines and their applications?

Sectional Warping Machine

- Used for weaving fabrics with complex patterns or designs

- Produces sectional beams with a specific number of ends per section

Beam Warping Machine

- Used for weaving fabrics with simple patterns or plain designs

- Produces beams with a continuous length of yarn

3. What are the key parameters to consider when setting up a warping machine?

- Yarn type and count

- Fabric width and density

- Warp beam size and length

- Machine speed and tension

- Environmental conditions (temperature and humidity)

4. How do you determine the optimal tension for warping yarn?

- Use a tension meter to measure the yarn tension

- Refer to the manufacturer’s recommendations for the yarn type

- Adjust the tension knobs on the warping machine to achieve the desired tension

5. Describe the process of creeling yarn for a warping machine?

- Inspect the yarn cones for any defects or knots

- Mount the yarn cones on the creel stand

- Connect the yarn ends to the warping machine’s yarn guides

- Adjust the yarn tension and ensure that all ends are running smoothly

6. Explain the importance of proper yarn preparation for warping?

- Reduces the risk of yarn breakage during warping

- Ensures uniform yarn tension and consistency in the woven fabric

- Improves the efficiency and productivity of the warping process

7. What are the common defects that can occur during warping and how can they be prevented?

- Yarn breakage: Can be caused by excessive tension, yarn defects, or improper machine setup

- Warp streaks: Occur when the yarn tension is uneven, resulting in variations in the fabric color or texture

- Twisted yarn: Occurs when the yarn is not properly guided or tensioned, resulting in the yarn twisting around itself

- End down: Occurs when a yarn end breaks or becomes detached from the warping machine, resulting in a missing end in the fabric

8. How do you maintain and troubleshoot warping machines?

- Regularly clean and lubricate the machine

- Inspect and replace worn or damaged parts

- Calibrate the machine according to the manufacturer’s instructions

- Troubleshoot common problems such as yarn breakage, tension issues, or electrical faults

9. Describe the safety precautions that must be followed when operating a warping machine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs

- Keep hands and loose clothing away from moving parts

- Ensure that the machine is properly grounded and electrically safe

- Follow lockout/tagout procedures when performing maintenance or repairs

10. Explain the role of warp quality in the overall fabric quality?

- High-quality warp ensures consistent yarn tension and weave pattern

- Reduces fabric defects such as yarn breakage, streaks, and end downs

- Improves the overall appearance, strength, and durability of the woven fabric

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warp Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warp Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Warp Worker is a crucial member of the textile production team, responsible for preparing and setting up the warp beam for the weaving process.

Their key job responsibilities include:

1. Preparing the Warp:

Determining the type and quantity of yarn required for the warp.

- Calculating the warp length and tension.

- Winding the yarn onto bobbins or beams.

2. Creeling the Warp:

Setting up the warp ends on the creel pegs.

- Ensuring the correct spacing and tension of the warp threads.

- Inspecting the warp threads for defects and removing any knots or breaks.

3. Drawing-In the Warp:

Threading the warp ends through the heddles and reed on the loom.

- Following the predetermined weave pattern.

- Inspecting the drawn-in warp for errors.

4. Beaming the Warp:

Transferring the drawn-in warp to the warp beam.

- Ensuring the proper tension and alignment of the warp threads.

- Inspecting the warp beam for defects and correcting any issues.

5. Assisting in Weaving:

Monitoring the weaving process and assisting the loom operator as needed.

- Troubleshooting weaving defects.

- Making minor adjustments to the loom settings.

Interview Tips

To ace the interview for a Warp Worker position, candidates should:

1. Research the Company and Position:

Understanding the company’s culture, products, and the specific requirements of the Warp Worker role will demonstrate your interest and preparation.

- Review the company website and job description thoroughly.

- Seek information about the industry and current trends in textile manufacturing.

2. Highlight Relevant Experience and Skills:

Emphasize your skills and knowledge in the areas of yarn preparation, creeling, drawing-in, beaming, and loom operations.

- Provide specific examples of your successful experiences in these tasks.

- Quantify your accomplishments whenever possible.

3. Demonstrate Attention to Detail and Quality:

Warp Workers play a vital role in ensuring the quality of the final fabric. Highlight your meticulousness and commitment to producing high-quality work.

- Explain your methods for inspecting and correcting errors.

- Share examples of how you have contributed to quality improvement initiatives.

4. Show Teamwork and Communication Skills:

Warp Workers often work closely with other team members. Showcase your ability to work effectively in a team environment and communicate clearly with supervisors and colleagues.

- Discuss your experiences in collaborating with others to achieve common goals.

- Provide examples of how you have effectively communicated technical information.

5. Be Prepared for Technical Questions:

The interviewer may ask technical questions to assess your knowledge of textile manufacturing processes. Be prepared to discuss:

- The different types of yarn used in textile production.

- The principles of weaving and the factors that affect fabric quality.

- Common weaving defects and how to troubleshoot them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warp Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!