Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Warper Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

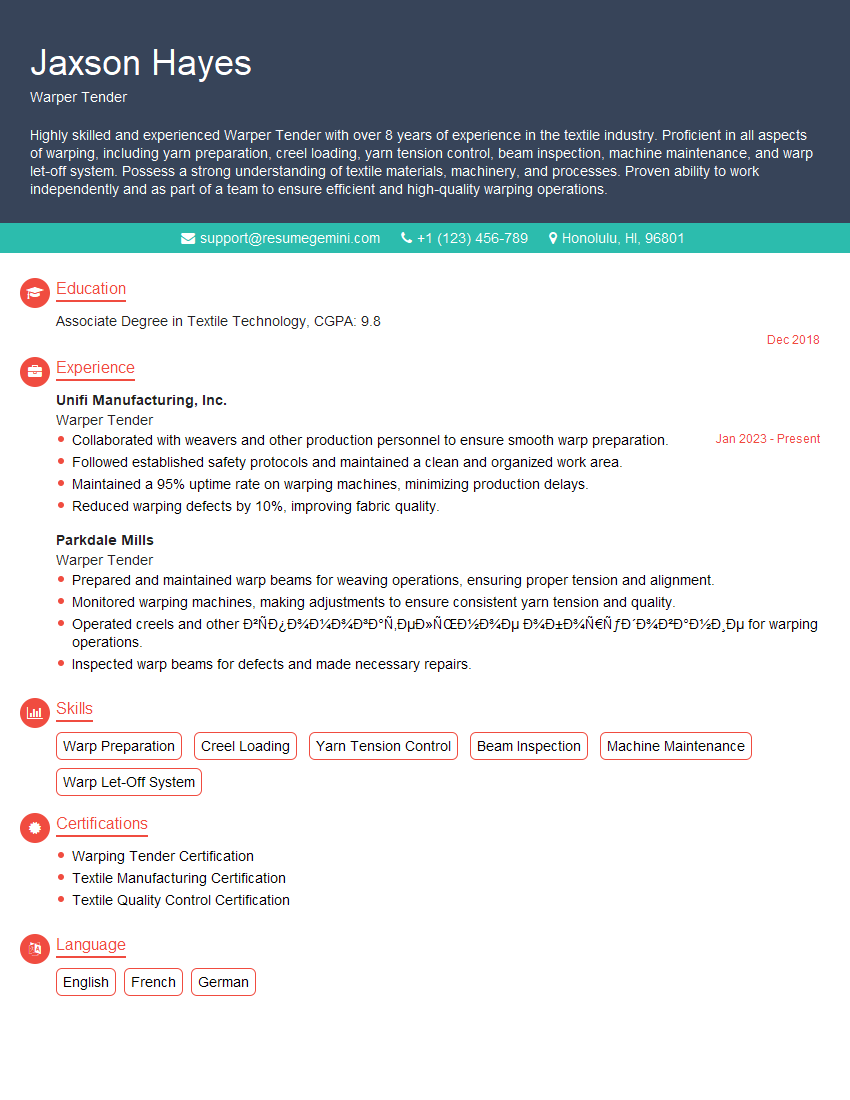

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warper Tender

1. How do you ensure proper tension during the warping process?

To ensure proper tension during warping, I follow these steps:

- Calibrate the tensioner regularly to maintain accurate tension readings.

- Monitor the tension throughout the process, making adjustments as needed to prevent yarn breakage or uneven winding.

- Use appropriate tension rods or weights to apply the correct amount of tension to the yarn.

2. Describe the process of checking and correcting yarn faults during warping.

Visual Inspection:

- Continuously observe the yarn for any visible defects, such as knots, slubs, or breaks.

Manual Detection:

- Use a yarn clearer or feeler to detect yarn faults by sensing changes in yarn thickness or tension.

Correction Measures:

- Stop the warping machine immediately upon detecting a fault.

- Locate the faulty section and remove it from the beam.

- Replace the faulty yarn with a new one and tie the ends together securely.

3. How do you maintain the cleanliness and organization of the warping area?

I maintain a clean and organized warping area by implementing the following practices:

- Regularly sweep and clean the floor to remove any debris or yarn waste.

- Keep all tools and equipment in designated areas to prevent clutter.

- Dispose of yarn waste properly to avoid accumulation.

4. Explain the different types of warping machines and their applications.

There are several types of warping machines, each with specific applications:

- Sectional Warping Machine: Used for sectional warping, creating precise warps for narrow fabrics.

- Beam Warping Machine: Used for beam warping, producing warps for wide fabrics and carpets.

- Jigger Warping Machine: Used for jigger warping, creating warps for special patterns or effects.

5. How do you calculate the required length of yarn for warping?

To calculate the required length of yarn for warping, I use the following formula:

Required Yarn Length = Warp Length × Ends per Warp × Total Warps

- Warp Length: Desired length of the finished fabric.

- Ends per Warp: Number of yarn ends used in each warp.

- Total Warps: Total number of warps required for the fabric.

6. What are the common causes of yarn breakage during warping and how do you prevent them?

Common causes of yarn breakage during warping include:

- Excessive Tension: Ensure proper tension settings to prevent yarn snapping.

- Yarn Faults: Check for weak spots, knots, or slubs in the yarn before warping.

- Sharp Edges: Inspect the machine for any sharp edges or burrs that may damage the yarn.

- Poor Creel Management: Ensure even yarn unwinding from the creel to prevent tangling.

7. How do you troubleshoot common problems encountered during the warping process?

To troubleshoot common warping problems, I follow these steps:

- Yarn Breakage: Check tension settings, yarn quality, and machine components for damage.

- Uneven Tension: Calibrate the tensioner, inspect the yarn path, and ensure proper alignment.

- Beam Distortion: Check for proper beam placement, adjust tension, and verify that the warping machine is level.

8. How do you ensure the quality of the finished warp?

To ensure the quality of the finished warp, I perform the following checks:

- Visual Inspection: Inspect the warp for any visible defects or unevenness.

- Tension Measurement: Measure the tension of the warp to ensure it meets specifications.

- Yarn Strength Test: Conduct tensile tests on the warp to verify its strength and durability.

9. What are the safety precautions to consider during the warping process?

To ensure safety during warping, I adhere to the following precautions:

- Wear appropriate safety gear, including gloves and eye protection.

- Keep long hair and loose clothing away from moving parts.

- Never attempt to repair or clear yarn faults while the machine is running.

- Follow lockout/tagout procedures before performing any maintenance or repairs.

10. How do you stay up-to-date with new technologies and best practices in the warping industry?

To stay current with industry advancements, I:

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Consult with experts in the field.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warper Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warper Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Warper tenders are responsible for operating and maintaining warping machines in textile mills. They perform a variety of tasks to ensure that the warps are produced according to specifications, including:

1. Preparing the warping machine

Warper tenders must prepare the warping machine for operation by cleaning the machine, checking the tension of the yarn, and making sure that the machine is functioning properly.

- Cleaning the machine

- Checking the tension of the yarn

- Making sure that the machine is functioning properly

2. Loading the yarn onto the machine

Warper tenders load the yarn onto the machine by feeding the yarn through the guides and onto the beams. They must ensure that the yarn is fed evenly and that the tension is correct.

- Feeding the yarn through the guides

- Loading the yarn onto the beams

- Ensuring that the yarn is fed evenly

- Ensuring that the tension is correct

3. Starting the machine and monitoring its operation

Warper tenders start the machine and monitor its operation to ensure that the warps are produced according to specifications. They must make adjustments to the machine as needed to maintain the correct speed, tension, and other factors.

- Starting the machine

- Monitoring its operation

- Making adjustments to the machine as needed

4. Inspecting the warps

Warper tenders inspect the warps after they have been produced to ensure that they meet specifications. They check for defects such as broken yarns, uneven tension, and other problems.

- Checking for defects such as broken yarns

- Checking for uneven tension

- Checking for other problems

Interview Tips

Interviewing for a Warper Tender position can be a challenging task, but by following these tips, you can increase your chances of success:

1. Do your research

Take some time to learn about the company and the Warper Tender position you are applying for. This will help you to answer questions intelligently and demonstrate your interest in the job.

- Visit the company website

- Read the job description carefully

- Talk to people who work in the textile industry

2. Prepare your answers to common interview questions

There are a few common questions that are often asked in Warper Tender interviews. By preparing your answers to these questions in advance, you can feel more confident and prepared during the interview.

- Why are you interested in this position?

- What experience do you have in operating and maintaining warping machines?

- What are your strengths and weaknesses as a Warper Tender?

- What are your salary expectations?

3. Dress appropriately

First impressions matter, so make sure to dress appropriately for your interview. This means wearing clean, pressed clothes that are appropriate for a professional setting.

- Wear a suit or dress pants and a button-down shirt

- Wear closed-toe shoes

- Avoid wearing jeans, t-shirts, or other casual clothing

4. Be polite and respectful

Be polite and respectful to everyone you meet during the interview process, including the receptionist, the interviewer, and other employees. This will show that you are a professional and that you are interested in making a good impression.

- Greet the interviewer with a firm handshake

- Make eye contact when you are speaking

- Be attentive and interested in what the interviewer has to say

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warper Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.