Are you gearing up for a career in Warping Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Warping Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

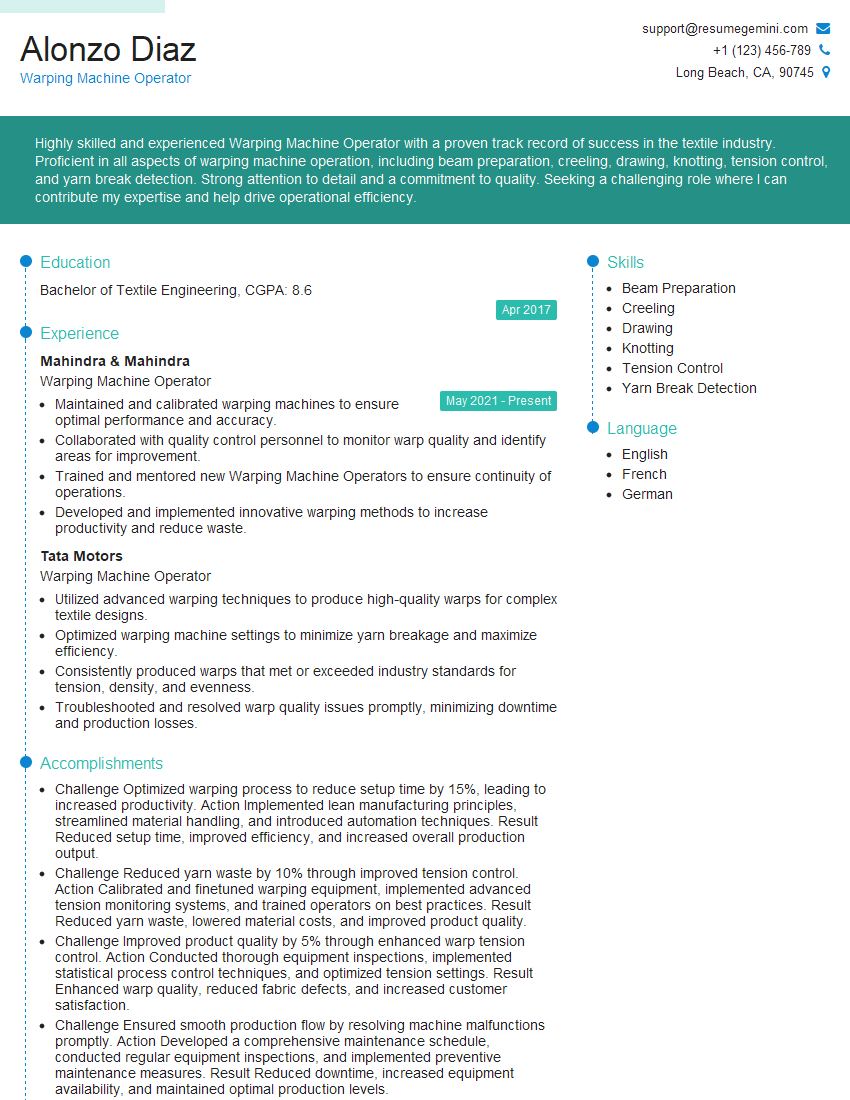

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Warping Machine Operator

1. Explain the process of warping?

Warping is the process of preparing the warp yarns for weaving. It involves unwinding the yarns from bobbins, arranging them in the correct order, and winding them onto a warp beam. The warp beam is then used on the warping machine, where the yarns are drawn through the heddles and the reed to form the warp shed.

2. What are the different types of warping machines?

Tape Warping Machine

- Used for warping yarns for high-speed weaving machines.

- Produces a warp beam with a high density of yarns.

Sectional Warping Machine

- Used for warping yarns for lower-speed weaving machines.

- Produces a warp beam with a lower density of yarns.

Beam Warping Machine

- Used for warping yarns for wide fabrics.

- Produces a warp beam with a large number of yarns.

3. What are the critical factors to consider when setting up a warping machine?

- Yarn tension

- Thread spacing

- Warp beam diameter

- Machine speed

4. How do you adjust the yarn tension on a warping machine?

- Check the tension of each yarn using a tension meter.

- Adjust the tension screw on the creel to tighten or loosen the tension.

- Confirm that the tension is within the specified range.

5. What are the common problems that you may encounter during warping, and how do you troubleshoot them?

Yarn Breakage

- Check yarn tension, creel, and thread path.

- Adjust tension, replace bobbins, or clear any obstructions.

Warp Distortion

- Check warp beam alignment, thread spacing, and machine speed.

- Adjust settings, realign the warp beam, or reduce machine speed.

6. What are the quality standards for a warped yarn beam?

- Even yarn tension throughout the beam

- Consistent thread spacing

- No yarn breaks or knots

- Beam diameter within tolerance

7. How do you maintain a warping machine?

- Regularly clean the machine to remove dust and debris.

- Check and replace worn or damaged parts.

- Calibrate the machine to ensure accuracy and consistency.

- Follow manufacturer’s instructions for maintenance intervals and procedures.

8. What are the safety precautions that you must observe when operating a warping machine?

- Wear appropriate personal protective equipment (PPE).

- Keep the machine area clean and free of obstructions.

- Never operate the machine with covers removed.

- Stop the machine before making any adjustments or repairs.

9. How do you calculate the length of yarn required for a warp beam?

- Determine the number of ends (yarns) in the warp.

- Measure the length of one end from creel to warping beam.

- Multiply the number of ends by the length of one end to get the total length required.

10. What is the purpose of a slasher in the warping process?

A slasher is a machine used to apply sizing to the warp yarns after warping. Sizing is a mixture of starch and other chemicals that helps to strengthen the yarns and protect them from damage during weaving.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Warping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Warping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Warping Machine Operators play a crucial role in the textile manufacturing process by preparing yarn for weaving. Their key responsibilities include:

1. Machine Operation

Operate warping machines to wind yarn onto beams, ensuring the yarn is evenly distributed and tensioned.

- Monitor machine operation and make necessary adjustments to maintain optimal tension and speed.

- Identify and correct any yarn defects or machine malfunctions.

2. Quality Control

Inspect the warped yarn for defects, such as knots, breaks, or uneven tension.

- Conduct regular checks to ensure the yarn meets the required specifications.

- Report any quality issues to supervisors promptly.

3. Material Handling

Handle and store materials, including yarn, beams, and creels, safely and efficiently.

- Load and unload warped beams onto machines and transport them to the next stage of production.

- Maintain a clean and organized work area.

4. Maintenance and Troubleshooting

Perform routine maintenance tasks, such as cleaning and lubricating machines.

- Troubleshoot machine problems and make minor repairs.

- Report major malfunctions to supervisors.

Interview Tips

To ace your interview for a Warping Machine Operator position, consider the following preparation tips:

1. Understand the Job Responsibilities

Thoroughly review the job description and key responsibilities outlined above. This will help you demonstrate your knowledge of the role.

- Prepare specific examples from your experience that align with each responsibility.

- Highlight your proficiency in operating warping machines, conducting quality control checks, and handling materials.

2. Research the Company

Visit the company’s website to learn about their products, services, and industry reputation.

- This will show the interviewer that you are interested in the company and have taken the initiative to learn about them.

- Mention specific reasons why you are interested in working for the company, such as their sustainability initiatives or commitment to innovation.

3. Practice Your Answers

Prepare for common interview questions by practicing your answers aloud.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Focus on showcasing your skills, experience, and enthusiasm for the role.

4. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview.

- Maintain eye contact, speak clearly, and show genuine interest in the position.

- Be prepared to ask insightful questions that demonstrate your engagement and understanding of the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Warping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.