Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Winder Contort Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

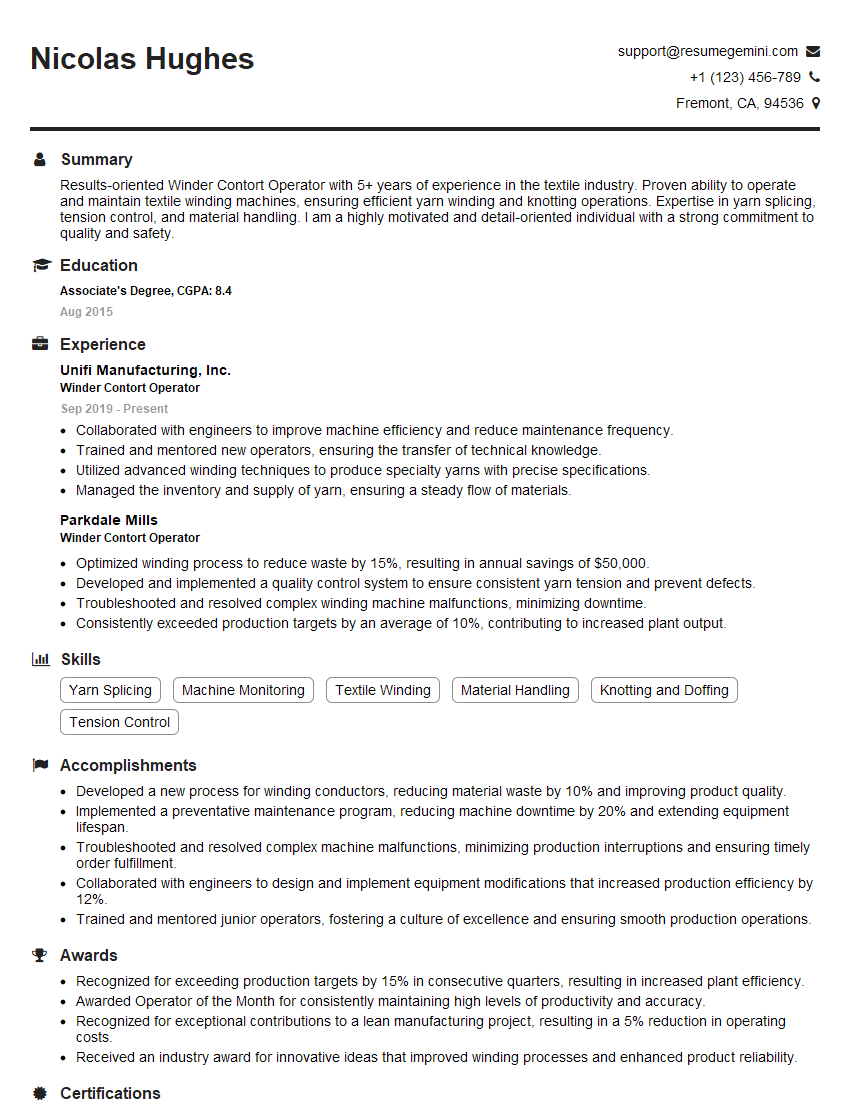

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winder Contort Operator

1. What are the key responsibilities of a Winder Contort Operator?

The key responsibilities of a Winder Contort Operator typically include:

- Operating and monitoring winding and contorting machines to produce yarn or thread.

- Inspecting yarn or thread for defects and making necessary adjustments to ensure quality.

- Maintaining and repairing winding and contorting equipment.

- Following established procedures and safety regulations.

- Collaborating with other operators to ensure smooth production.

2. How do you ensure the quality of the yarn or thread produced?

Checking Raw Materials:

- Inspecting the incoming yarn or fiber for any defects or inconsistencies.

- Verifying the quality against established standards and specifications.

Monitoring Production Process:

- Observing the winding and contorting process to identify any abnormalities.

- Conducting regular checks on tension, speed, and moisture levels.

Testing and Inspection:

- Sampling the finished yarn or thread to assess its quality.

- Performing tests for strength, elasticity, and other relevant properties.

3. What types of winding and contorting machines have you operated?

I have experience operating various winding and contorting machines, including:

- Automatic winding machines

- Semi-automatic winding machines

- Cone winding machines

- Hank winding machines

- Contorting machines

- Twisting machines

4. What are some common problems that can occur during winding and contorting?

Some common problems that can occur during winding and contorting include:

- Yarn breakage due to excessive tension or weak fibers.

- Uneven winding or contorting, resulting in inconsistent product quality.

- Machine malfunctions, such as motor failures or sensor issues.

- Yarn contamination from dust or other particles.

- Improper threading or setup, leading to production delays.

5. How do you troubleshoot and resolve machine problems?

Problem Identification:

- Observing the machine’s behavior and identifying any unusual sounds, vibrations, or visual cues.

- Checking error codes or messages displayed on the machine’s interface.

Troubleshooting:

- Consulting technical manuals or seeking guidance from experienced colleagues.

- Inspecting the machine’s components, such as belts, gears, and sensors.

- Performing diagnostic tests to pinpoint the root cause of the problem.

Resolution:

- Replacing or repairing faulty components.

- Adjusting machine settings or parameters.

- Re-threading the yarn or fiber to eliminate tension issues.

6. What are the safety precautions you follow when operating winding and contorting machines?

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Maintaining a clean and organized work area to prevent tripping hazards.

- Following lockout/tagout procedures before servicing or repairing machines.

- Being aware of moving parts and potential pinch points.

- Reporting any unsafe conditions or potential hazards to supervisors.

7. How do you maintain and calibrate winding and contorting machines?

Preventive Maintenance:

- Regularly cleaning and lubricating machine components.

- Inspecting belts, gears, and bearings for wear or damage.

- Checking tension settings and making necessary adjustments.

Calibration:

- Using specialized tools or equipment to calibrate winding speed, tension, and other parameters.

- Ensuring that machines meet industry standards and produce consistent yarn or thread.

- Documenting calibration procedures and results for traceability.

8. What steps do you take to minimize waste and improve efficiency in your work?

To minimize waste and improve efficiency, I take the following steps:

- Optimizing winding tension to reduce yarn breakage.

- Adjusting machine settings to minimize downtime for changeovers.

- Repurposing leftover yarn or thread for other applications.

- Regularly monitoring machine performance and identifying areas for improvement.

- Sharing best practices with other operators to promote knowledge transfer.

9. What is your experience with quality control procedures in the textile industry?

- Conducting in-process inspections to check yarn or thread quality.

- Using statistical process control (SPC) to monitor production and identify trends.

- Analyzing quality data and implementing corrective actions to improve product quality.

- Adhering to industry standards and customer specifications.

- Working with quality assurance teams to ensure product consistency.

10. How do you stay updated with the latest advancements in winding and contorting technology?

- Attending industry conferences and workshops.

- Reading technical publications and trade magazines.

- Participating in online forums and networking with other professionals.

- Seeking training opportunities from equipment manufacturers.

- Staying informed about new product releases and technological innovations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winder Contort Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winder Contort Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Winder Contort Operator plays a crucial role in the wire and cable manufacturing industry. Their primary responsibility is to operate and monitor the winder contort machine, which efficiently winds and packages electrical wires and cables.

1. Machine Operation and Monitoring

The operator is expected to:

- Set up, calibrate, and operate the winder contort machine with precision to ensure optimal performance.

- Continuously monitor the machine’s operation, identifying and resolving any technical issues promptly to minimize downtime and maintain productivity.

2. Wire and Cable Handling

The operator is responsible for:

- Inspecting incoming electrical wires and cables to ensure they meet specifications and are free from defects.

- Feeding the wires and cables into the winder contort machine accurately and efficiently, ensuring proper tension and winding patterns.

3. Quality Control and Inspection

The operator is tasked with:

- Performing regular quality checks on the wound wires and cables, verifying that they meet the required specifications and standards.

- Maintaining detailed records and documentation of the quality control checks, ensuring traceability and accountability.

4. Maintenance and Troubleshooting

The operator is expected to:

- Regularly perform preventive maintenance on the winder contort machine, following established procedures to ensure optimal functioning.

- Troubleshoot and resolve minor technical issues, ensuring minimal interruptions to the production process.

Interview Tips

Preparing thoroughly for a Winder Contort Operator interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific role. This will demonstrate your genuine interest and enthusiasm for the position.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating winder contort machines and your understanding of wire and cable manufacturing processes. Quantify your accomplishments with specific examples to showcase your capabilities.

3. Practice Common Interview Questions

Prepare for common interview questions, such as “Tell me about your experience in operating winder contort machines” or “How do you ensure quality control in wire and cable manufacturing?” Practicing your answers will boost your confidence and articulation.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and engagement. This shows the interviewer that you are genuinely interested in the role and the company.

5. Follow Up Professionally

After the interview, send a brief follow-up email thanking the interviewer for their time and reiterating your interest in the position. This follow-up shows your professionalism and leaves a positive impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Winder Contort Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!