Are you gearing up for an interview for a Wood Die Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wood Die Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

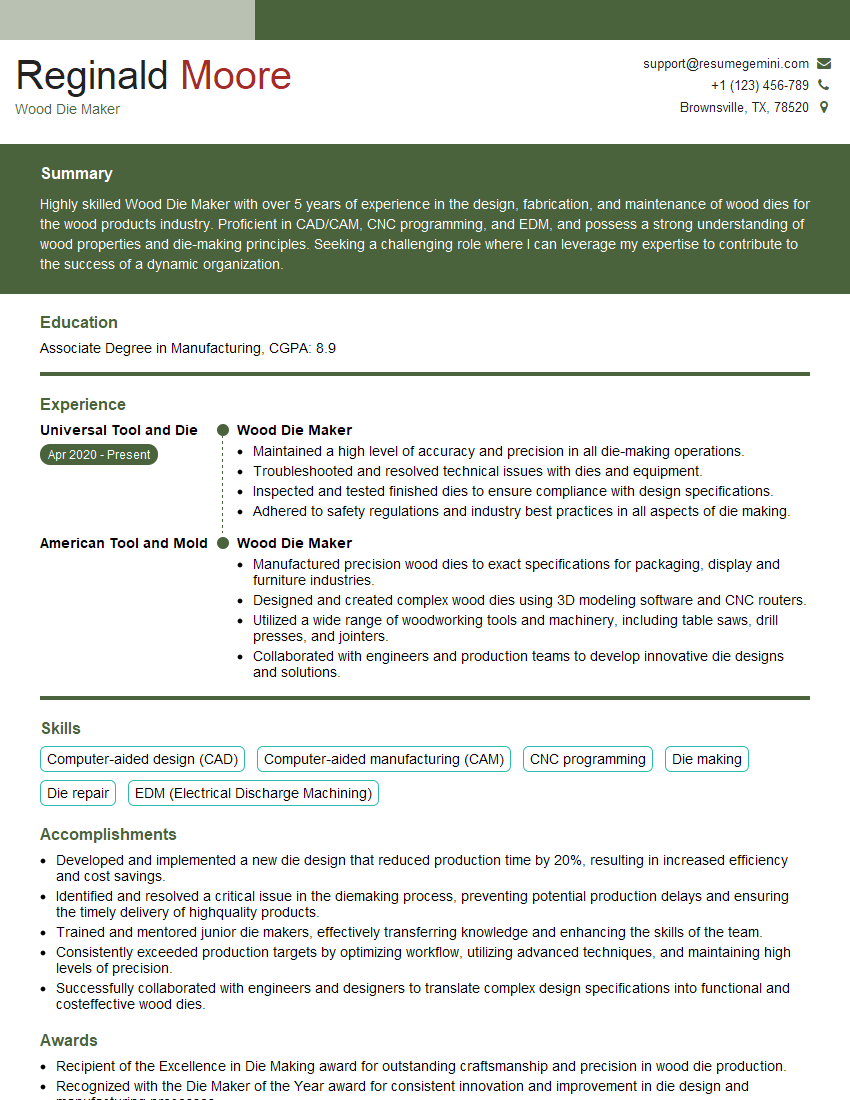

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Die Maker

1. Explain the process of creating a wood die?

The process of creating a wood die involves the following steps:

- Select the appropriate wood for the die, considering factors such as hardness, durability, and grain pattern.

- Design the die using CAD software or hand sketches, ensuring precision and accuracy in dimensions and tolerances.

- Cut the wood to the desired shape and size using saws, routers, or other woodworking tools.

- Carve or engrave the die’s cutting and forming surfaces using specialized tools such as gouges, chisels, and CNC machines.

- Heat-treat the die to enhance its durability and reduce wear during use.

- Grind and polish the die to achieve the desired surface finish and sharpness.

- Inspect and test the die to ensure it meets specifications and performs as intended.

2. What are the different types of wood dies and their applications?

Cutting Dies

- Used to cut materials such as leather, paper, rubber, and thin metal.

- Types include flatbed dies, rotary dies, and clicker dies.

Forming Dies

- Used to shape materials into specific forms.

- Types include bending dies, embossing dies, and coining dies.

Matching Dies

- Used in pairs to cut or form materials simultaneously.

- Ensure precision and consistency in product dimensions.

3. What are the key factors to consider when designing a wood die?

- Material properties of the wood, including hardness, grain direction, and moisture content.

- Dimensions and tolerances required for the die’s intended application.

- Type of cutting or forming process to be performed.

- Durability and longevity requirements of the die.

- Cost and availability of the wood material.

4. What are the common techniques used for engraving wood dies?

- Hand carving with gouges and chisels.

- CNC engraving using computer-controlled machines.

- Laser engraving for precise and intricate designs.

- Photoengraving for creating images and patterns.

5. How do you ensure precision and accuracy in wood die making?

- Use accurate measuring instruments and reference surfaces.

- Employ jigs and fixtures to guide cutting and engraving tools.

- Regularly calibrate and maintain equipment.

- Conduct thorough inspections and testing throughout the die-making process.

6. What are the common challenges faced in wood die making and how do you overcome them?

- Wood shrinkage: Use properly seasoned wood and control humidity levels during storage and use.

- Grain direction: Consider grain direction and select wood with appropriate grain patterns for the desired application.

- Wear and tear: Use durable wood species, heat-treat the die, and apply protective coatings to extend its lifespan.

- Precision requirements: Employ precise cutting and engraving techniques, use jigs and fixtures, and conduct rigorous testing to meet specifications.

7. How do you maintain and store wood dies to ensure longevity?

- Clean the die thoroughly after each use to remove any debris or residue.

- Apply protective coatings such as wax or oil to prevent moisture absorption and damage.

- Store the die in a controlled environment with stable temperature and humidity levels.

- Periodically inspect and sharpen the die to maintain its cutting or forming capabilities.

8. What are the latest advancements and trends in wood die making technology?

- CNC engraving: Advanced CNC machines offer precision and efficiency in die engraving.

- Laser engraving: Lasers provide high-resolution engraving for intricate designs and micro-features.

- 3D printing: 3D printing enables rapid prototyping and production of complex wood dies.

- Composite materials: Engineered wood composites offer enhanced strength and durability compared to traditional wood.

9. How do you stay updated with the latest developments in wood die making techniques?

- Attend industry conferences and workshops.

- Read trade publications and articles.

- Engage with online forums and communities.

- Seek training from experienced wood die makers or manufacturers.

10. What are some examples of successful applications of wood dies in various industries?

- Automotive: Cutting and forming leather and fabric for upholstery and interior components.

- Packaging: Die-cutting cardboard and paperboard for boxes and containers.

- Footwear: Embossing and forming leather and synthetic materials for shoes and boots.

- Electronics: Die-cutting gaskets and spacers for electronic devices.

- Medical: Creating molds for prosthetic limbs and orthotics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Die Makers are responsible for fabricating and repairing wooden dies, jigs, fixtures, and patterns used in the manufacturing process. They work closely with engineers and designers to create precise and functional components that meet specific requirements.

1. Fabrication and Repair

Wood Die Makers use a variety of tools and equipment to create and repair wooden dies, including saws, routers, jointers, and sanders. They must have a thorough understanding of wood properties and machining techniques to ensure that the dies are durable and accurate.

- Fabricate wooden dies, jigs, fixtures, and patterns according to specifications.

- Repair and maintain wooden dies and other components.

2. Inspection and Quality Control

Wood Die Makers are responsible for inspecting and testing dies to ensure they meet specifications and quality standards. They use precision measuring tools and gauges to verify dimensions, tolerances, and surface finishes.

- Inspect dies for defects and ensure they meet specifications.

- Conduct quality control tests and make adjustments as necessary.

3. Collaboration and Communication

Wood Die Makers work closely with engineers, designers, and other team members to develop and implement solutions. They must be able to communicate effectively and provide clear and concise instructions to ensure that the dies are manufactured accurately and efficiently.

- Collaborate with engineers and designers to develop dies.

- Provide instructions and guidance to other team members.

4. Safety and Maintenance

Wood Die Makers must adhere to safety regulations and maintain a clean and organized work environment. They are responsible for inspecting and maintaining equipment and tools to ensure they are in good working order.

- Follow safety regulations and maintain a clean work environment.

- Inspect and maintain equipment and tools.

Interview Tips

Preparing for a job interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry news and articles to learn about the company’s products, services, and competitors.

- Review the job description carefully and identify the key skills and qualifications required for the position.

2. Practice Your Answers

Once you have a good understanding of the company and position, practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Write down a list of potential questions and practice answering them out loud.

- Ask a friend or family member to conduct a mock interview with you.

- Record yourself answering questions and review your performance.

3. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for your interview. Arrive on time, or even a few minutes early, to show that you are punctual and respectful of the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Pay attention to your grooming and make sure your hair is neat and your fingernails are clean.

- Allow yourself plenty of time to get to the interview location and factor in any potential traffic delays.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and passionate about their work. Show the interviewer that you are genuinely interested in the position and the company. Be positive and upbeat, and don’t be afraid to share your excitement about the opportunity.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Highlight your passion for your work and your desire to contribute to the company’s success.

5. Follow Up

After the interview, be sure to follow up with the interviewer to thank them for their time and express your continued interest in the position. This shows that you are professional and respectful, and it can help you stay top-of-mind for the interviewer.

- Send a handwritten thank-you note or an email within 24 hours of the interview.

- Reiterate your interest in the position and highlight any specific skills or experiences that you feel would be valuable to the company.

- Inquire about the next steps in the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wood Die Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!