Are you gearing up for a career in Wood Machine Carver? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wood Machine Carver and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

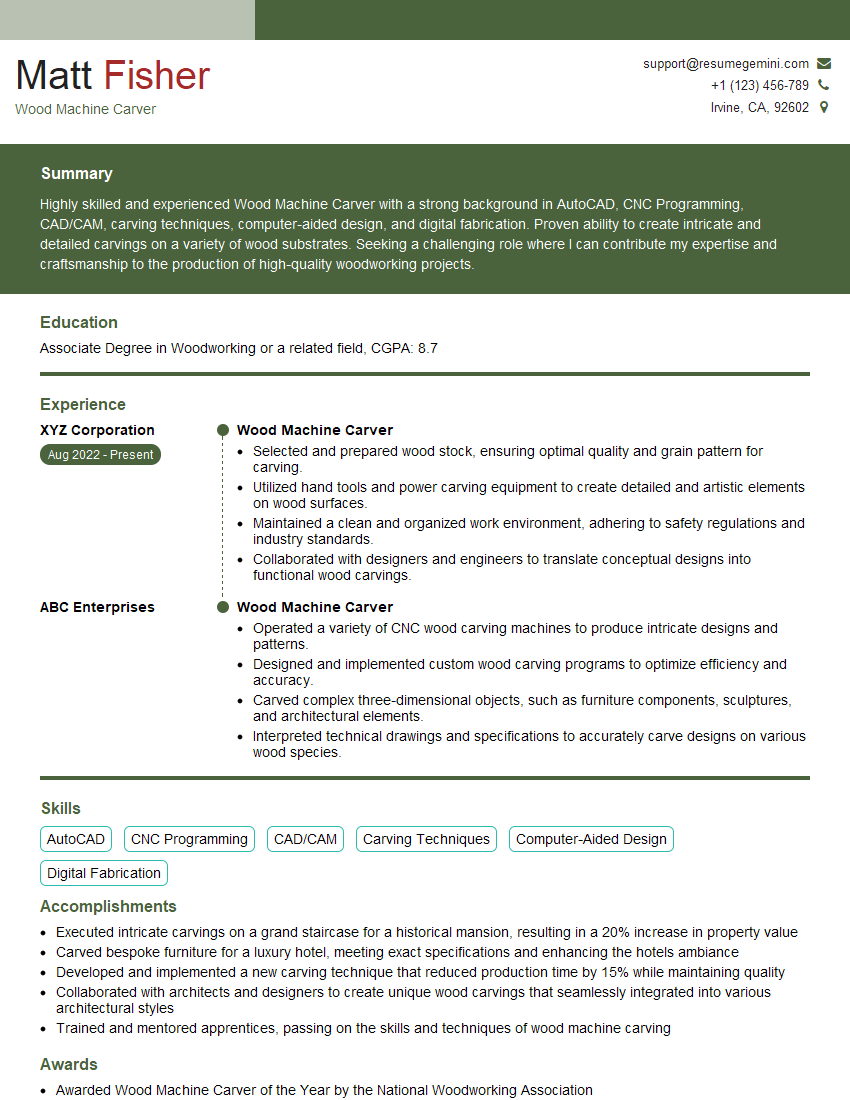

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Machine Carver

1. What are the different types of wood carving machines and their uses?

- CNC Router: Computer Numerical Controlled (CNC) routers are used for precise and detailed carving. They are computer-controlled and can create complex designs.

- Laser Engraver: Laser engravers use a focused laser beam to etch designs into wood. They are suitable for creating intricate designs and logos.

- Spindle Carver: Spindle carvers use high-speed rotating spindles with cutting bits to carve wood. They are used for creating 3D carvings and sculptures.

- Sanding Machine: Sanding machines are used to smooth and finish carved surfaces. They can use different grits of sandpaper to achieve the desired smoothness.

2. What factors should be considered when selecting a wood carving machine?

Factors to Consider

- Type of carving: Determine the type of carving you want to do (e.g., 3D carving, engraving, intricate designs).

- Material: Consider the type of wood you will be carving and its hardness.

- Precision and accuracy: Assess the level of precision and accuracy required for your projects.

- Size and complexity: Determine the size and complexity of the carvings you plan to make.

- Budget: Establish a budget for purchasing and maintaining the machine.

3. How do you ensure the quality and precision of wood carvings?

- Proper machine calibration: Ensure that the wood carving machine is calibrated correctly to achieve precise cuts.

- Sharp cutting tools: Use sharp cutting bits or blades to prevent tearing or splintering of the wood.

- Careful material selection: Choose high-quality wood that is free from knots or defects to minimize imperfections.

- Test cuts and adjustments: Make test cuts to adjust the settings and optimize the carving process.

- Regular maintenance: Perform regular maintenance on the machine to ensure smooth operation and prevent errors.

4. What safety precautions should be taken when operating a wood carving machine?

- Wear appropriate safety gear: Use safety glasses, earplugs, and a dust mask to protect yourself from flying debris and noise.

- Secure the workpiece: Ensure that the wood is securely clamped or held in place to prevent accidents.

- Maintain a clean work area: Keep the work area clean and free from obstacles to prevent tripping or slipping.

- Follow machine instructions: Read and understand the operating instructions of the machine before using it.

- Avoid loose clothing and jewelry: Loose clothing or jewelry can get caught in the machinery, posing a safety hazard.

5. What techniques can be used to achieve different wood carving effects?

- Carving with different bits: Use various carving bits to create different shapes and textures.

- Varying carving depths: Adjust the carving depth to achieve different levels of detail and relief.

- Using multiple passes: Repeat carving passes over the same area to refine the details and smooth the surface.

- Sanding and finishing: Use sandpaper and finishing techniques to enhance the appearance of the carving.

- Applying textures: Use texturing tools to add unique patterns or textures to the carved surface.

6. How do you maintain and troubleshoot wood carving machines?

- Regular cleaning and lubrication: Clean and lubricate the machine regularly to maintain its performance.

- Inspecting cutting tools: Check the cutting bits for wear or damage and replace them if necessary.

- Calibrating the machine: Recalibrate the machine periodically to ensure accuracy and precision.

- Troubleshooting common issues: Familiarize yourself with common problems that can occur and their solutions.

- Seeking professional assistance: Contact a qualified technician for complex repairs or troubleshooting.

7. What types of wood are best suited for wood carving and why?

- Hardwoods: Hardwoods like oak, maple, and walnut are dense and durable, making them ideal for detailed carvings.

- Softwoods: Softwoods like pine and cedar are softer and easier to carve, suitable for beginners or less intricate designs.

- Seasoned wood: Seasoned wood has been dried to reduce moisture content, making it less prone to warping or cracking.

- Grain orientation: Consider the grain orientation of the wood to achieve the desired aesthetic effect.

- Knots and defects: Avoid wood with excessive knots or defects, as they can hinder carving and compromise the final product.

8. What are the different ways to finish wood carvings?

- Sanding: Use sandpaper to smooth the surface and remove any rough edges.

- Oiling: Apply oil to protect the wood and enhance its natural beauty.

- Varnishing: Use varnish to create a protective layer and add a glossy finish.

- Staining: Apply stain to change the color or enhance the grain pattern of the wood.

- Waxing: Use wax to provide a protective coating and add a subtle sheen.

9. What design principles should be considered when creating wood carvings?

- Proportion: Ensure the proportions of the carving are balanced and aesthetically pleasing.

- Composition: Arrange the elements of the carving to create a cohesive and visually appealing design.

- Contrast: Use contrasting elements to create visual interest and depth.

- Rhythm: Create a sense of movement and flow through the repetition or variation of elements.

- Focal point: Establish a focal point to draw the viewer’s attention to the main subject of the carving.

10. Describe your experience in using different wood carving techniques and tools.

- CNC routing: Explain your proficiency in operating CNC routers and creating complex designs.

- Laser engraving: Describe your experience in using laser engravers to produce intricate engravings and logos.

- Spindle carving: Share your knowledge and skills in using spindle carvers to create 3D sculptures.

- Sanding and finishing: Showcase your expertise in sanding and finishing techniques to enhance the appearance of wood carvings.

- Safety protocols: Emphasize your understanding and adherence to safety protocols when operating wood carving machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Machine Carver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Machine Carver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wood Machine Carver is responsible for creating decorative or functional objects from wood using specialized machinery, including CNC routers, carving machines, and lathes. They work with a variety of wood types and finishes to produce intricate designs and patterns.

1. Machine Operation

Operate and maintain CNC routers, carving machines, and lathes to create wood products according to specifications.

- Set up and calibrate machines for optimal performance.

- Load and unload wood materials and ensure proper alignment.

- Monitor production processes and make adjustments as needed.

2. Design and Programming

Create or interpret designs and specifications for wood products.

- Use computer-aided design (CAD) software to develop and modify designs.

- Generate CNC programs that control the movement of machines.

- Develop toolpaths to optimize efficiency and minimize waste.

3. Finishing and Quality Control

Apply finishes to protect and enhance the appearance of wood products.

- Sand, stain, and seal wood surfaces to achieve desired results.

- Inspect products for quality and accuracy before packaging and shipping.

- Identify and correct any defects or imperfections.

4. Maintenance and Safety

Maintain and repair machinery and equipment to ensure optimal performance.

- Perform regular cleaning and lubrication of machines.

- Troubleshoot and resolve mechanical issues promptly.

- Follow safety protocols and wear appropriate protective gear.

Interview Tips

Preparing thoroughly for your Wood Machine Carver interview will increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to learn about the company’s values, products, and industry reputation. Research the specific requirements of the Wood Machine Carver role and identify your skills and experiences that align with those requirements.

- Review the company website, social media pages, and online reviews.

- Identify key words in the job description and highlight how your qualifications match.

2. Showcase Your Technical Skills

During the interview, be prepared to demonstrate your proficiency in operating CNC routers, carving machines, and lathes. Provide specific examples of projects you have worked on that highlight your abilities.

- Quantify your accomplishments by providing specific metrics, such as the number of parts produced or the reduction in waste achieved.

- Bring a portfolio or examples of your work if possible.

3. Highlight Your Safety and Maintenance Knowledge

Emphasize your understanding of safety protocols and procedures for operating machinery, handling tools, and working with hazardous materials.

- Explain how you maintain and troubleshoot equipment to ensure optimal performance.

- Discuss your experience with safety training and certifications.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This is an opportunity to clarify your understanding of the role and to show that you are engaged and proactive.

- Inquire about the company’s growth plans, innovation strategies, or industry trends.

- Ask about training and development opportunities for employees.

Next Step:

Now that you’re armed with the knowledge of Wood Machine Carver interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wood Machine Carver positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini