Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wood Milling Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wood Milling Machine Tender so you can tailor your answers to impress potential employers.

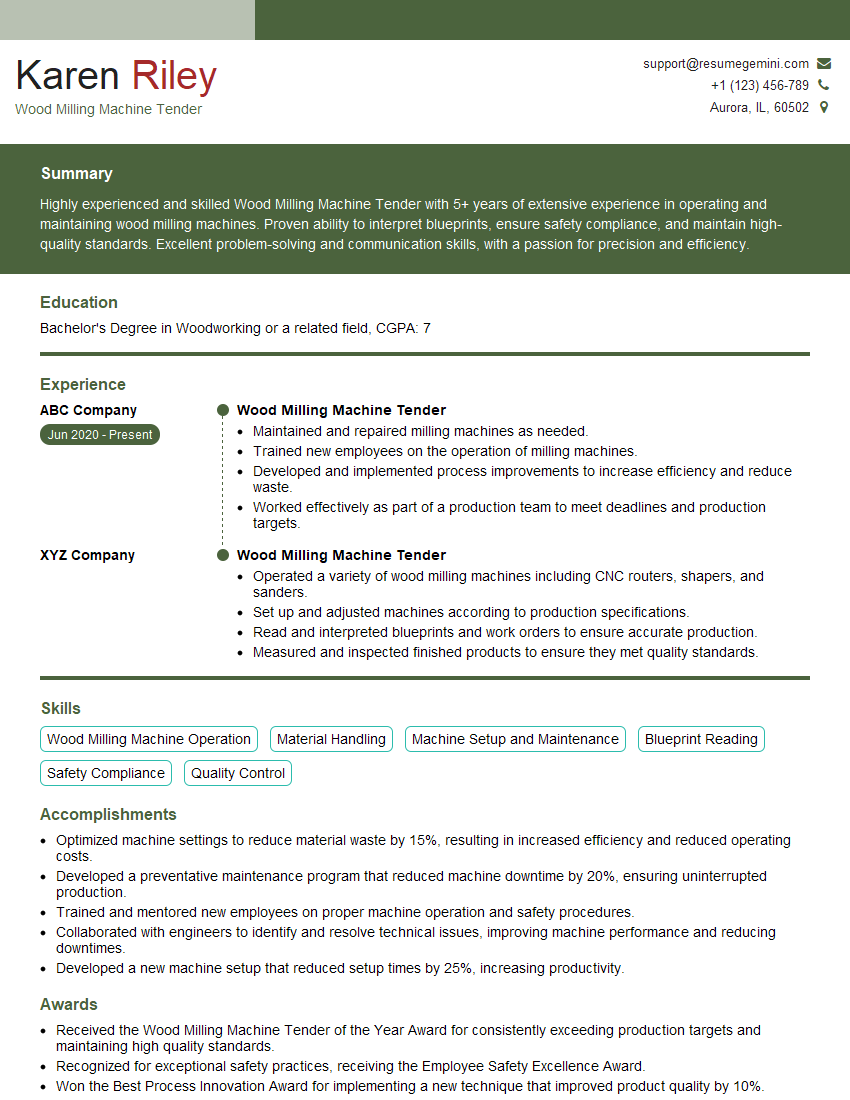

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wood Milling Machine Tender

1. What are the different types of wood milling machines?

There are several types of wood milling machines, each designed for specific tasks. Some of the most common types include:

- Horizontal spindle moulders: These machines have a spindle that is mounted horizontally and can be used for a variety of operations, such as shaping, moulding, and profiling.

- Vertical spindle moulders: These machines have a spindle that is mounted vertically and are used for tasks such as routing, mortising, and tenoning.

- Planers: These machines have a large, flat table that moves the workpiece past a rotating cutter, which removes material from the surface.

- Jointers: These machines have a rotating cutter that is used to create a flat, even surface on the edge of a workpiece.

- Shapers: These machines have a rotating cutter that is used to create decorative shapes on the edge of a workpiece.

2. What are the safety precautions that must be taken when operating a wood milling machine?

- Wear proper safety gear, including safety glasses, earplugs, and a dust mask.

- Inspect the machine before each use to ensure that it is in good working order.

- Secure the workpiece properly before starting the machine.

- Keep your hands away from the cutter while the machine is running.

- Never operate the machine while under the influence of alcohol or drugs.

Emergency stop procedure

- If an emergency occurs, press the emergency stop button immediately.

- Once the machine has stopped, turn off the power and unplug the machine.

- Do not attempt to restart the machine until the emergency has been resolved.

3. What are the different types of wood milling cutters?

There are many different types of wood milling cutters, each designed for a specific purpose. Some of the most common types include:

- Straight cutters: These cutters have a straight cutting edge and are used for tasks such as grooving, rabbeting, and dadoing.

- Dovetail cutters: These cutters have a V-shaped cutting edge and are used for cutting dovetails.

- Ogee cutters: These cutters have a curved cutting edge and are used for creating decorative shapes.

- Panel raisers: These cutters have a wide cutting edge and are used for raising panels in cabinet doors and other woodworking projects.

- Stile and rail cutters: These cutters have a combination of straight and curved cutting edges and are used for cutting stiles and rails for doors and windows.

4. How do you choose the right wood milling cutter for a specific task?

When choosing a wood milling cutter, there are several factors to consider, including:

- The type of operation being performed (e.g., grooving, rabbeting, dadoing, etc.)

- The type of wood being used

- The desired depth of cut

- The speed of the machine

- The feed rate

Once these factors have been considered, you can select a wood milling cutter that is designed for the specific task you are performing.

5. What are the different types of jigs and fixtures that can be used with a wood milling machine?

There are many different types of jigs and fixtures that can be used with a wood milling machine to help ensure accuracy and repeatability. Some of the most common types include:

- Featherboards: These jigs help to keep the workpiece pressed against the fence, which prevents it from moving during the cutting operation.

- Stop blocks: These jigs help to ensure that the workpiece is cut to the correct length.

- Templates: These jigs are used to create complex shapes in the workpiece.

- Clamps: These fixtures are used to hold the workpiece in place during the cutting operation.

- Vise: This fixture is used to hold small workpieces in place.

6. How do you maintain a wood milling machine?

To maintain a wood milling machine, it is important to:

- Clean the machine regularly to remove sawdust and other debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for wear and tear, and replace any damaged parts.

- Sharpen the cutters regularly to ensure that they are cutting properly.

- Follow the manufacturer’s instructions for storage and transportation.

7. What are the common problems that can occur with a wood milling machine?

Some of the common problems that can occur with a wood milling machine include:

- The machine is not cutting properly: This can be caused by a number of factors, including dull cutters, improper feed rate, or a misaligned fence.

- The machine is making excessive noise: This can be caused by a number of factors, including worn bearings, a loose belt, or a damaged cutter.

- The machine is vibrating excessively: This can be caused by a number of factors, including an unbalanced cutter, a loose spindle, or a misaligned fence.

- The machine is overheating: This can be caused by a number of factors, including a clogged air filter, a faulty motor, or a lack of lubrication.

8. How do you troubleshoot problems with a wood milling machine?

To troubleshoot problems with a wood milling machine, it is important to:

- Identify the problem.

- Determine the cause of the problem.

- Resolve the problem.

- Test the machine to ensure that the problem has been resolved.

If you are unable to resolve the problem on your own, you should contact a qualified technician for assistance.

9. What are the advantages of using a wood milling machine?

- Accuracy: Wood milling machines are very accurate, which makes them ideal for creating precise cuts.

- Repeatability: Wood milling machines can be used to create multiple identical cuts, which is ideal for production work.

- Versatility: Wood milling machines can be used to perform a wide variety of operations, including cutting, shaping, and profiling.

- Efficiency: Wood milling machines can be used to speed up the production process, which can save time and money.

10. What are the disadvantages of using a wood milling machine?

- Cost: Wood milling machines can be expensive to purchase and maintain.

- Complexity: Wood milling machines can be complex to operate, which requires training and experience.

- Safety: Wood milling machines can be dangerous to use, which requires proper safety precautions.

- Noise: Wood milling machines can be noisy, which can be a nuisance in some environments.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wood Milling Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wood Milling Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wood Milling Machine Tenders are responsible for operating and monitoring wood milling machines to produce lumber, wood products, and other wood-based materials. They ensure that the machines are operating safely and efficiently, and that the products meet quality standards.

1. Operating Wood Milling Machines

Wood Milling Machine Tenders operate a variety of wood milling machines, including planers, jointers, shapers, and saws. They set up the machines according to specifications, and then feed wood into the machines to be processed. They monitor the machines during operation, and make adjustments as needed to ensure that the products meet quality standards.

2. Inspecting Wood Products

Wood Milling Machine Tenders inspect the wood products produced by the machines to ensure that they meet quality standards. They check for defects such as knots, cracks, and splits. They also measure the products to ensure that they are the correct size and shape.

3. Maintaining Wood Milling Machines

Wood Milling Machine Tenders perform routine maintenance on wood milling machines to ensure that they are operating safely and efficiently. They clean the machines, lubricate moving parts, and replace worn or damaged parts.

4. Troubleshooting Wood Milling Machines

Wood Milling Machine Tenders troubleshoot wood milling machines when they malfunction. They identify the cause of the problem, and then make repairs or adjustments to fix the machine.

Interview Tips

Preparing for an interview for a Wood Milling Machine Tender position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions in advance, so that you can deliver your responses confidently and clearly.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in operating wood milling machines. Be prepared to discuss your skills and knowledge, and to provide examples of your work.

4. Be Yourself

It is important to be yourself during the interview. The interviewer wants to get to know you and to see if you are a good fit for the company and the position. Don’t try to be someone you’re not.

5. Dress Professionally

First impressions matter, so make sure to dress professionally for the interview. This shows that you are serious about the position and that you respect the interviewer’s time.

6. Be Punctual

Punctuality is important for any job interview, but it is especially important for a job interview for a Wood Milling Machine Tender position. This shows that you are reliable and that you are able to manage your time well.

7. Be Enthusiastic

Enthusiasm is contagious, so make sure to show the interviewer that you are excited about the position. This will make the interviewer more likely to see you as a good fit for the company.

8. Ask Questions

At the end of the interview, the interviewer will give you an opportunity to ask questions. This is your chance to learn more about the company and the position, and to show the interviewer that you are interested in the job.

Next Step:

Now that you’re armed with the knowledge of Wood Milling Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wood Milling Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini