Are you a seasoned 1st Pressman seeking a new career path? Discover our professionally built 1st Pressman Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

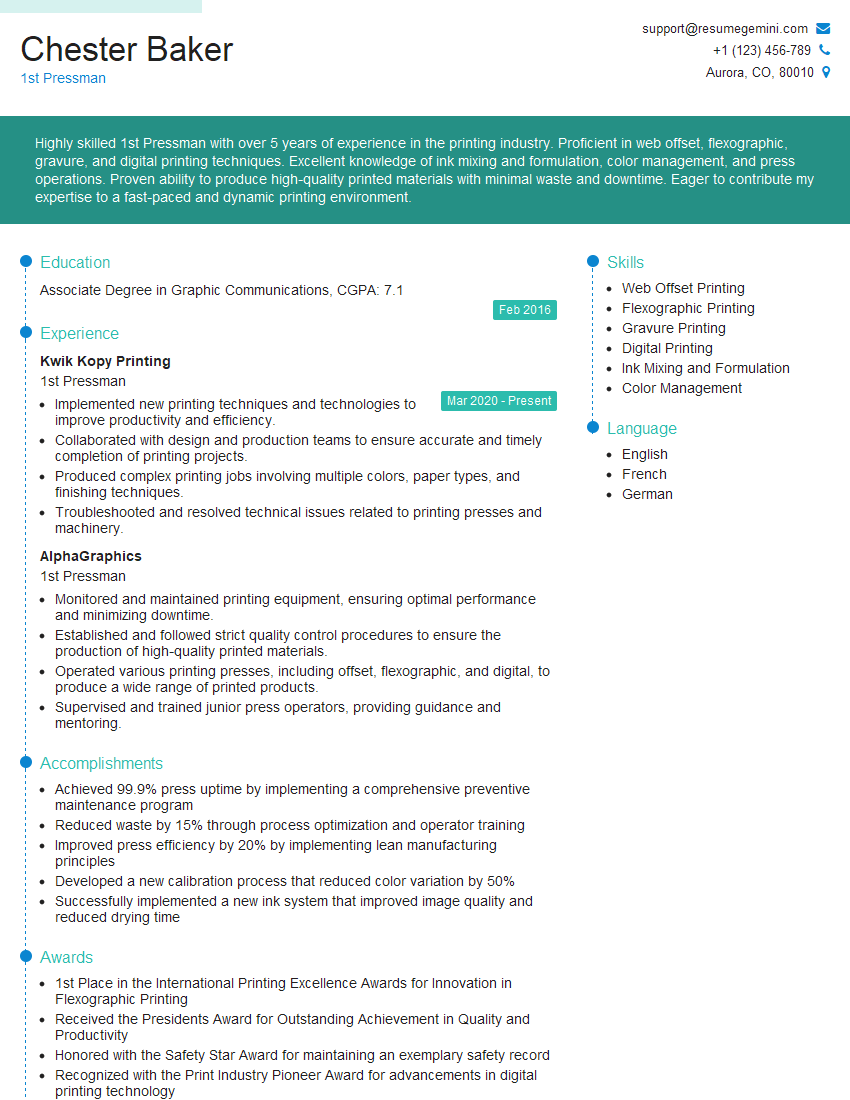

Chester Baker

1st Pressman

Summary

Highly skilled 1st Pressman with over 5 years of experience in the printing industry. Proficient in web offset, flexographic, gravure, and digital printing techniques. Excellent knowledge of ink mixing and formulation, color management, and press operations. Proven ability to produce high-quality printed materials with minimal waste and downtime. Eager to contribute my expertise to a fast-paced and dynamic printing environment.

Education

Associate Degree in Graphic Communications

February 2016

Skills

- Web Offset Printing

- Flexographic Printing

- Gravure Printing

- Digital Printing

- Ink Mixing and Formulation

- Color Management

Work Experience

1st Pressman

- Implemented new printing techniques and technologies to improve productivity and efficiency.

- Collaborated with design and production teams to ensure accurate and timely completion of printing projects.

- Produced complex printing jobs involving multiple colors, paper types, and finishing techniques.

- Troubleshooted and resolved technical issues related to printing presses and machinery.

1st Pressman

- Monitored and maintained printing equipment, ensuring optimal performance and minimizing downtime.

- Established and followed strict quality control procedures to ensure the production of high-quality printed materials.

- Operated various printing presses, including offset, flexographic, and digital, to produce a wide range of printed products.

- Supervised and trained junior press operators, providing guidance and mentoring.

Accomplishments

- Achieved 99.9% press uptime by implementing a comprehensive preventive maintenance program

- Reduced waste by 15% through process optimization and operator training

- Improved press efficiency by 20% by implementing lean manufacturing principles

- Developed a new calibration process that reduced color variation by 50%

- Successfully implemented a new ink system that improved image quality and reduced drying time

Awards

- 1st Place in the International Printing Excellence Awards for Innovation in Flexographic Printing

- Received the Presidents Award for Outstanding Achievement in Quality and Productivity

- Honored with the Safety Star Award for maintaining an exemplary safety record

- Recognized with the Print Industry Pioneer Award for advancements in digital printing technology

Certificates

- Certified Printing Production Specialist (CPPS)

- Certified Digital Press Operator (CDPO)

- Gravure Printing Specialist (GPS)

- Flexographic Printing Specialist (FPS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For 1st Pressman

- Highlight your experience and skills in the printing industry, especially in web offset, flexographic, gravure, and digital printing.

- Showcase your knowledge of ink mixing and formulation, color management, and press operations.

- Provide specific examples of your ability to produce high-quality printed materials with minimal waste and downtime.

- Demonstrate your understanding of press maintenance and troubleshooting procedures.

Essential Experience Highlights for a Strong 1st Pressman Resume

- Operate and maintain printing presses to produce a variety of printed materials, including brochures, flyers, posters, and packaging.

- Mix and formulate inks according to specifications to ensure accurate color reproduction.

- Calibrate and maintain press equipment to achieve optimal print quality.

- Monitor press performance and make adjustments as needed to minimize waste and downtime.

- Inspect printed materials for defects and ensure they meet quality standards.

- Troubleshoot and resolve press issues to maintain efficient production flow.

- Maintain a clean and organized work environment and adhere to safety protocols.

Frequently Asked Questions (FAQ’s) For 1st Pressman

What are the key skills and qualifications required to become a 1st Pressman?

Key skills and qualifications include proficiency in web offset, flexographic, gravure, and digital printing techniques, ink mixing and formulation, color management, and press operations.

What is the role of a 1st Pressman in the printing industry?

A 1st Pressman is responsible for operating and maintaining printing presses to produce a variety of printed materials, such as brochures, flyers, posters, and packaging.

What are the career prospects for a 1st Pressman?

With experience and additional training, a 1st Pressman can advance to supervisory or management positions within the printing industry.

What is the average salary range for a 1st Pressman?

The average salary range for a 1st Pressman varies depending on experience, location, and company size.

What are the working conditions like for a 1st Pressman?

1st Pressmen typically work in a fast-paced and demanding environment, involving exposure to noise, ink, and chemicals.

What is the job outlook for a 1st Pressman?

The job outlook for a 1st Pressman is expected to decline slightly due to technological advancements and automation in the printing industry.

What are the educational requirements for a 1st Pressman?

While not always required, many 1st Pressmen hold an associate degree or certificate in graphic communications or a related field.