Are you a seasoned Abrasive Mixer seeking a new career path? Discover our professionally built Abrasive Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

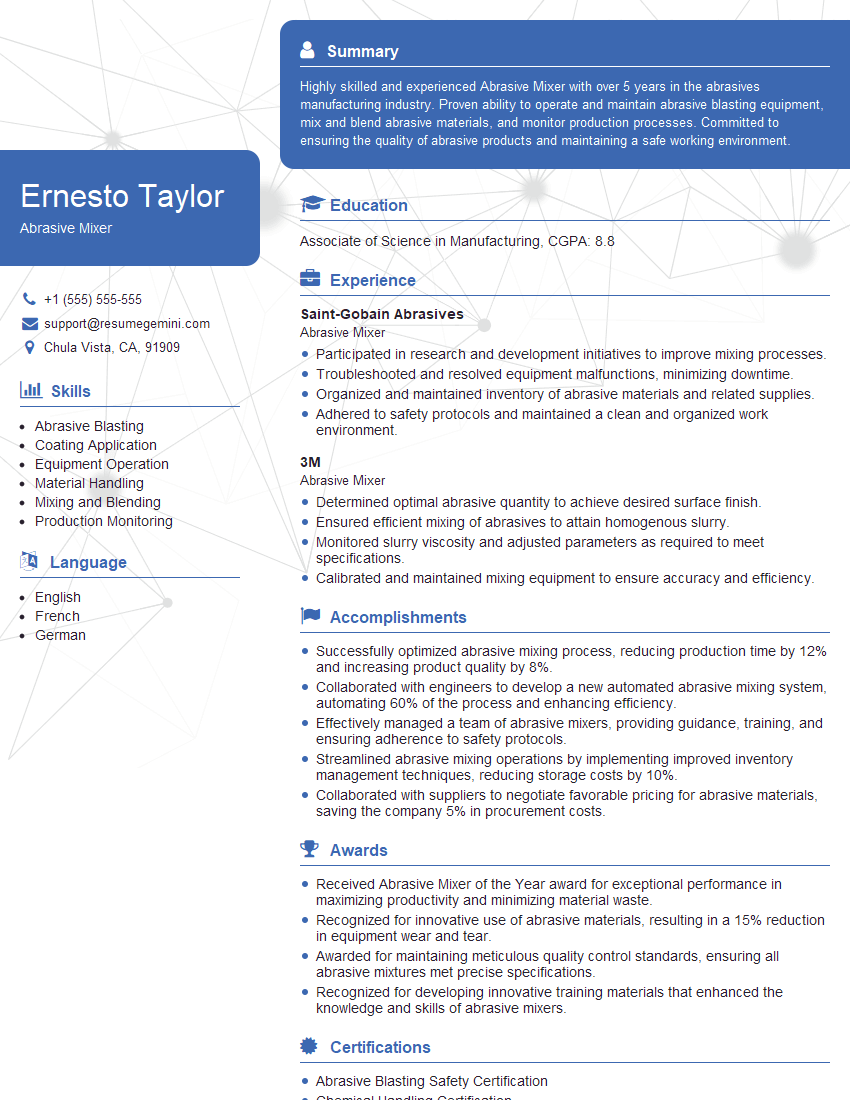

Ernesto Taylor

Abrasive Mixer

Summary

Highly skilled and experienced Abrasive Mixer with over 5 years in the abrasives manufacturing industry. Proven ability to operate and maintain abrasive blasting equipment, mix and blend abrasive materials, and monitor production processes. Committed to ensuring the quality of abrasive products and maintaining a safe working environment.

Education

Associate of Science in Manufacturing

February 2017

Skills

- Abrasive Blasting

- Coating Application

- Equipment Operation

- Material Handling

- Mixing and Blending

- Production Monitoring

Work Experience

Abrasive Mixer

- Participated in research and development initiatives to improve mixing processes.

- Troubleshooted and resolved equipment malfunctions, minimizing downtime.

- Organized and maintained inventory of abrasive materials and related supplies.

- Adhered to safety protocols and maintained a clean and organized work environment.

Abrasive Mixer

- Determined optimal abrasive quantity to achieve desired surface finish.

- Ensured efficient mixing of abrasives to attain homogenous slurry.

- Monitored slurry viscosity and adjusted parameters as required to meet specifications.

- Calibrated and maintained mixing equipment to ensure accuracy and efficiency.

Accomplishments

- Successfully optimized abrasive mixing process, reducing production time by 12% and increasing product quality by 8%.

- Collaborated with engineers to develop a new automated abrasive mixing system, automating 60% of the process and enhancing efficiency.

- Effectively managed a team of abrasive mixers, providing guidance, training, and ensuring adherence to safety protocols.

- Streamlined abrasive mixing operations by implementing improved inventory management techniques, reducing storage costs by 10%.

- Collaborated with suppliers to negotiate favorable pricing for abrasive materials, saving the company 5% in procurement costs.

Awards

- Received Abrasive Mixer of the Year award for exceptional performance in maximizing productivity and minimizing material waste.

- Recognized for innovative use of abrasive materials, resulting in a 15% reduction in equipment wear and tear.

- Awarded for maintaining meticulous quality control standards, ensuring all abrasive mixtures met precise specifications.

- Recognized for developing innovative training materials that enhanced the knowledge and skills of abrasive mixers.

Certificates

- Abrasive Blasting Safety Certification

- Chemical Handling Certification

- Environmental Protection Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Abrasive Mixer

- Quantify your accomplishments with specific metrics to showcase your impact.

- Highlight your knowledge of abrasive blasting and mixing techniques and materials.

- Emphasize your commitment to safety and quality control.

- Obtain necessary certifications, such as the National Institute for Certification in Engineering Technologies (NICET).

- Network with professionals in the abrasives industry to expand your knowledge and career opportunities.

Essential Experience Highlights for a Strong Abrasive Mixer Resume

- Operate and maintain abrasive blasting equipment, including mixers, hoppers, and air compressors.

- Mix and blend abrasive materials according to specified formulations to achieve desired properties.

- Monitor production processes and make adjustments to ensure product quality and consistency.

- Maintain work areas and equipment in a clean and organized manner.

- Troubleshoot and resolve equipment malfunctions and production issues.

- Adhere to safety regulations and protocols to ensure a safe working environment.

- Collaborate with other team members to ensure smooth production operations.

Frequently Asked Questions (FAQ’s) For Abrasive Mixer

What are the primary duties of an Abrasive Mixer?

Abrasive Mixers are responsible for operating and maintaining abrasive blasting equipment, mixing and blending abrasive materials, and monitoring production processes to ensure product quality and consistency.

What skills are required to be an Abrasive Mixer?

Abrasive Mixers typically possess skills in abrasive blasting, coating application, equipment operation, material handling, mixing and blending, and production monitoring.

What is the work environment of an Abrasive Mixer?

Abrasive Mixers typically work in manufacturing facilities and may be exposed to noise, dust, and hazardous chemicals.

What are the career advancement opportunities for Abrasive Mixers?

With experience and additional training, Abrasive Mixers can advance to positions such as Production Supervisor, Quality Control Inspector, or Technical Sales Representative.

What certifications are beneficial for Abrasive Mixers?

Abrasive Mixers can obtain certifications from organizations such as the National Institute for Certification in Engineering Technologies (NICET) to enhance their credibility and career prospects.

What is the average salary of an Abrasive Mixer?

The average salary of an Abrasive Mixer can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for Abrasive Mixers in the United States is around $45,000 per year.

What is the job outlook for Abrasive Mixers?

The job outlook for Abrasive Mixers is expected to be favorable in the coming years due to the increasing demand for abrasive products in various industries.