Are you a seasoned Abrasive Wheel Molder seeking a new career path? Discover our professionally built Abrasive Wheel Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

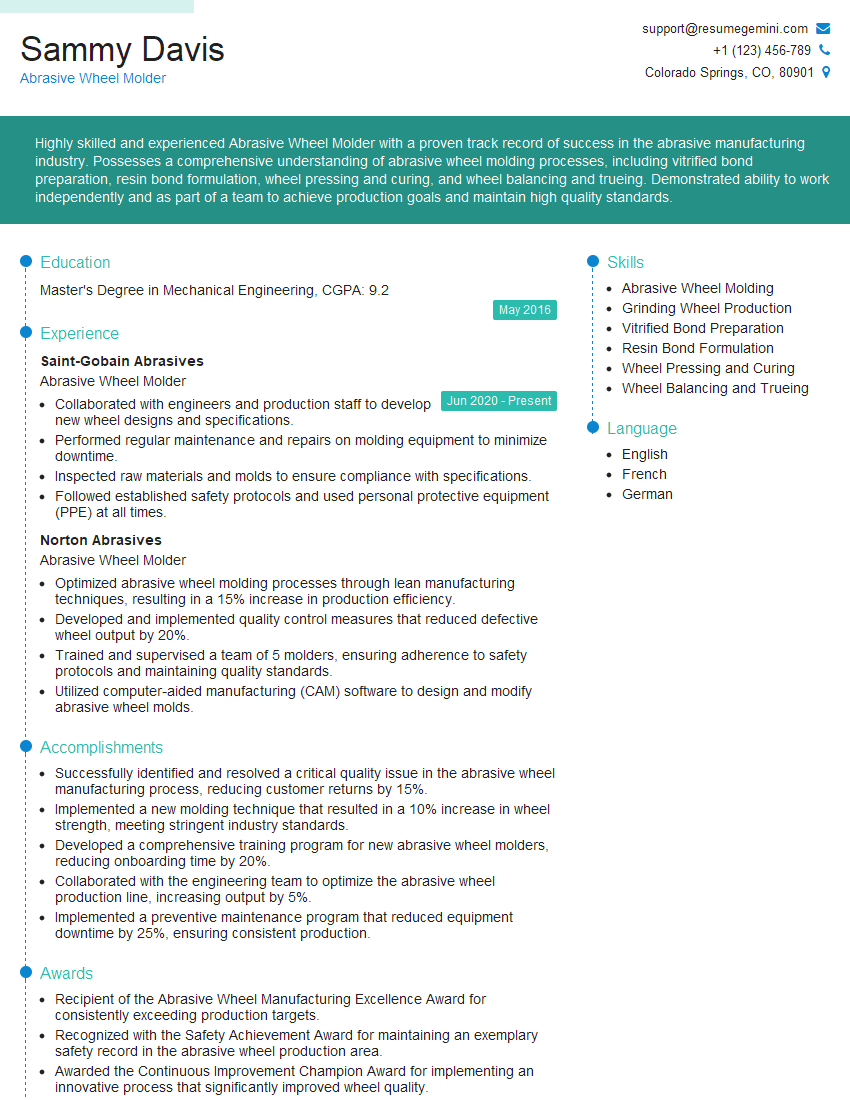

Sammy Davis

Abrasive Wheel Molder

Summary

Highly skilled and experienced Abrasive Wheel Molder with a proven track record of success in the abrasive manufacturing industry. Possesses a comprehensive understanding of abrasive wheel molding processes, including vitrified bond preparation, resin bond formulation, wheel pressing and curing, and wheel balancing and trueing. Demonstrated ability to work independently and as part of a team to achieve production goals and maintain high quality standards.

Education

Master’s Degree in Mechanical Engineering

May 2016

Skills

- Abrasive Wheel Molding

- Grinding Wheel Production

- Vitrified Bond Preparation

- Resin Bond Formulation

- Wheel Pressing and Curing

- Wheel Balancing and Trueing

Work Experience

Abrasive Wheel Molder

- Collaborated with engineers and production staff to develop new wheel designs and specifications.

- Performed regular maintenance and repairs on molding equipment to minimize downtime.

- Inspected raw materials and molds to ensure compliance with specifications.

- Followed established safety protocols and used personal protective equipment (PPE) at all times.

Abrasive Wheel Molder

- Optimized abrasive wheel molding processes through lean manufacturing techniques, resulting in a 15% increase in production efficiency.

- Developed and implemented quality control measures that reduced defective wheel output by 20%.

- Trained and supervised a team of 5 molders, ensuring adherence to safety protocols and maintaining quality standards.

- Utilized computer-aided manufacturing (CAM) software to design and modify abrasive wheel molds.

Accomplishments

- Successfully identified and resolved a critical quality issue in the abrasive wheel manufacturing process, reducing customer returns by 15%.

- Implemented a new molding technique that resulted in a 10% increase in wheel strength, meeting stringent industry standards.

- Developed a comprehensive training program for new abrasive wheel molders, reducing onboarding time by 20%.

- Collaborated with the engineering team to optimize the abrasive wheel production line, increasing output by 5%.

- Implemented a preventive maintenance program that reduced equipment downtime by 25%, ensuring consistent production.

Awards

- Recipient of the Abrasive Wheel Manufacturing Excellence Award for consistently exceeding production targets.

- Recognized with the Safety Achievement Award for maintaining an exemplary safety record in the abrasive wheel production area.

- Awarded the Continuous Improvement Champion Award for implementing an innovative process that significantly improved wheel quality.

Certificates

- OSHA Abrasive Wheel Safety

- Certified Abrasive Wheel Molder (CAWM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Abrasive Wheel Molder

- Highlight your expertise in abrasive wheel molding processes and your ability to achieve consistent, high-quality results.

- Showcase your knowledge of vitrified and resin bond formulations, emphasizing your ability to optimize wheel performance for specific applications.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Demonstrate your commitment to safety and quality by highlighting your adherence to industry standards and best practices.

Essential Experience Highlights for a Strong Abrasive Wheel Molder Resume

- Prepare vitrified and resin bonds according to established formulations to ensure optimal wheel performance and longevity.

- Operate wheel presses to mold abrasive wheels to precise specifications, ensuring proper shape, size, and density.

- Cure molded wheels in kilns or ovens to achieve desired hardness, strength, and durability.

- Balance and true wheels using specialized equipment to ensure smooth and vibration-free operation.

- Conduct quality control inspections to verify wheel dimensions, hardness, and balance meet customer requirements.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

- Collaborate with engineers and production team to optimize molding processes and troubleshoot any issues that arise.

Frequently Asked Questions (FAQ’s) For Abrasive Wheel Molder

What are the primary responsibilities of an Abrasive Wheel Molder?

Abrasive Wheel Molders are responsible for preparing vitrified and resin bonds, operating wheel presses, curing molded wheels, balancing and trueing wheels, conducting quality control inspections, maintaining a clean work area, and collaborating with engineers and production teams.

What skills are essential for an Abrasive Wheel Molder?

Essential skills for Abrasive Wheel Molders include abrasive wheel molding, grinding wheel production, vitrified bond preparation, resin bond formulation, wheel pressing and curing, wheel balancing and trueing, and quality control.

What is the typical work environment for an Abrasive Wheel Molder?

Abrasive Wheel Molders typically work in manufacturing facilities, operating machinery and equipment in a production environment. They may also work in laboratories or research and development settings.

What are the career prospects for an Abrasive Wheel Molder?

Abrasive Wheel Molders with experience and expertise can advance to roles such as Supervisor, Production Manager, or Quality Control Manager. They may also specialize in specific areas of abrasive wheel manufacturing, such as vitrified bond preparation or resin bond formulation.

What are the safety precautions that Abrasive Wheel Molders must follow?

Abrasive Wheel Molders must follow strict safety precautions, including wearing appropriate safety gear, using machinery and equipment correctly, and adhering to established safety protocols. They must also be aware of the potential hazards associated with working with abrasive materials and take necessary precautions to minimize risks.

How can I become an Abrasive Wheel Molder?

To become an Abrasive Wheel Molder, you typically need a high school diploma or equivalent qualification and relevant work experience in the abrasive manufacturing industry. Some employers may also require a college degree in Mechanical Engineering or a related field.

What is the average salary for an Abrasive Wheel Molder?

The average salary for an Abrasive Wheel Molder can vary depending on factors such as experience, location, and employer. According to Indeed, the average salary for Abrasive Wheel Molders in the United States is around \$25 per hour.