Are you a seasoned Acetylene Torch Solderer seeking a new career path? Discover our professionally built Acetylene Torch Solderer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

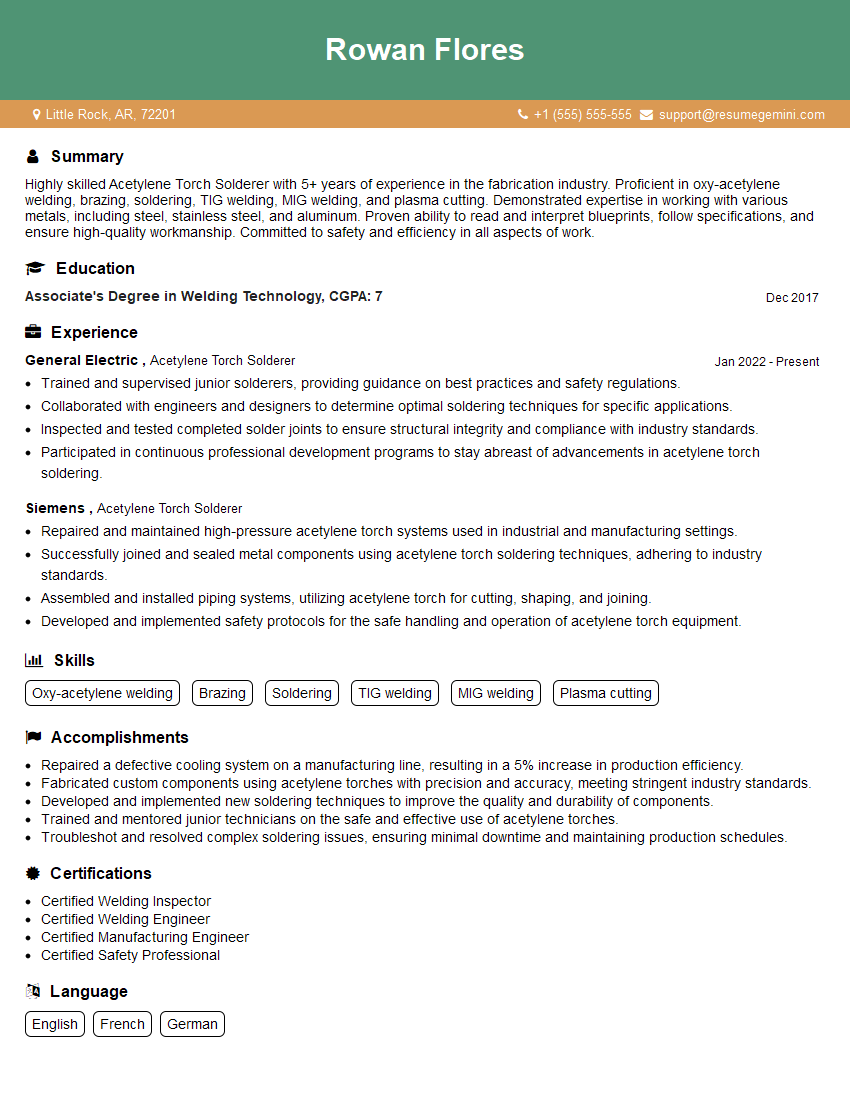

Rowan Flores

Acetylene Torch Solderer

Summary

Highly skilled Acetylene Torch Solderer with 5+ years of experience in the fabrication industry. Proficient in oxy-acetylene welding, brazing, soldering, TIG welding, MIG welding, and plasma cutting. Demonstrated expertise in working with various metals, including steel, stainless steel, and aluminum. Proven ability to read and interpret blueprints, follow specifications, and ensure high-quality workmanship. Committed to safety and efficiency in all aspects of work.

Education

Associate’s Degree in Welding Technology

December 2017

Skills

- Oxy-acetylene welding

- Brazing

- Soldering

- TIG welding

- MIG welding

- Plasma cutting

Work Experience

Acetylene Torch Solderer

- Trained and supervised junior solderers, providing guidance on best practices and safety regulations.

- Collaborated with engineers and designers to determine optimal soldering techniques for specific applications.

- Inspected and tested completed solder joints to ensure structural integrity and compliance with industry standards.

- Participated in continuous professional development programs to stay abreast of advancements in acetylene torch soldering.

Acetylene Torch Solderer

- Repaired and maintained high-pressure acetylene torch systems used in industrial and manufacturing settings.

- Successfully joined and sealed metal components using acetylene torch soldering techniques, adhering to industry standards.

- Assembled and installed piping systems, utilizing acetylene torch for cutting, shaping, and joining.

- Developed and implemented safety protocols for the safe handling and operation of acetylene torch equipment.

Accomplishments

- Repaired a defective cooling system on a manufacturing line, resulting in a 5% increase in production efficiency.

- Fabricated custom components using acetylene torches with precision and accuracy, meeting stringent industry standards.

- Developed and implemented new soldering techniques to improve the quality and durability of components.

- Trained and mentored junior technicians on the safe and effective use of acetylene torches.

- Troubleshot and resolved complex soldering issues, ensuring minimal downtime and maintaining production schedules.

Certificates

- Certified Welding Inspector

- Certified Welding Engineer

- Certified Manufacturing Engineer

- Certified Safety Professional

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Acetylene Torch Solderer

- Highlight your experience with acetylene torches and other welding techniques.

- Showcase your knowledge of welding codes and safety regulations.

- Include examples of projects where you have successfully used acetylene torches.

- Quantify your results whenever possible, using specific numbers or metrics.

Essential Experience Highlights for a Strong Acetylene Torch Solderer Resume

- Operate acetylene torch to solder, braze, and weld metal components

- Prepare and clean metal surfaces for welding and soldering

- Inspect welds and soldered joints for quality and strength

- Follow blueprints and work orders to ensure accuracy and precision

- Maintain a clean and organized work area

- Adhere to safety protocols and wear appropriate personal protective equipment

- Collaborate with other team members to complete projects efficiently

Frequently Asked Questions (FAQ’s) For Acetylene Torch Solderer

What is the primary responsibility of an Acetylene Torch Solderer?

The primary responsibility of an Acetylene Torch Solderer is to use an acetylene torch to join and repair metal components by soldering, brazing, and welding.

What are the key skills required for an Acetylene Torch Solderer?

The key skills required for an Acetylene Torch Solderer include oxy-acetylene welding, brazing, soldering, TIG welding, MIG welding, and plasma cutting.

What are the educational requirements for an Acetylene Torch Solderer?

Most Acetylene Torch Solderers have at least an associate’s degree in welding technology or a related field.

What are the career prospects for an Acetylene Torch Solderer?

Acetylene Torch Solderers with experience and expertise can advance to positions such as welding supervisor, welding inspector, or welding engineer.

What are the key tips for writing a standout Acetylene Torch Solderer resume?

Highlight your experience with acetylene torches and other welding techniques, showcase your knowledge of welding codes and safety regulations, include examples of projects where you have successfully used acetylene torches, and quantify your results whenever possible, using specific numbers or metrics.

What are the safety precautions that an Acetylene Torch Solderer should follow?

Acetylene Torch Solderers should always wear appropriate personal protective equipment, including a welding helmet, gloves, and protective clothing. They should also ensure that their work area is well-ventilated and free of flammable materials.

What are the different types of metals that an Acetylene Torch Solderer can work with?

Acetylene Torch Solderers can work with a variety of metals, including steel, stainless steel, aluminum, and copper.