Are you a seasoned Aircraft Body and Bonded Structure Repairer seeking a new career path? Discover our professionally built Aircraft Body and Bonded Structure Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

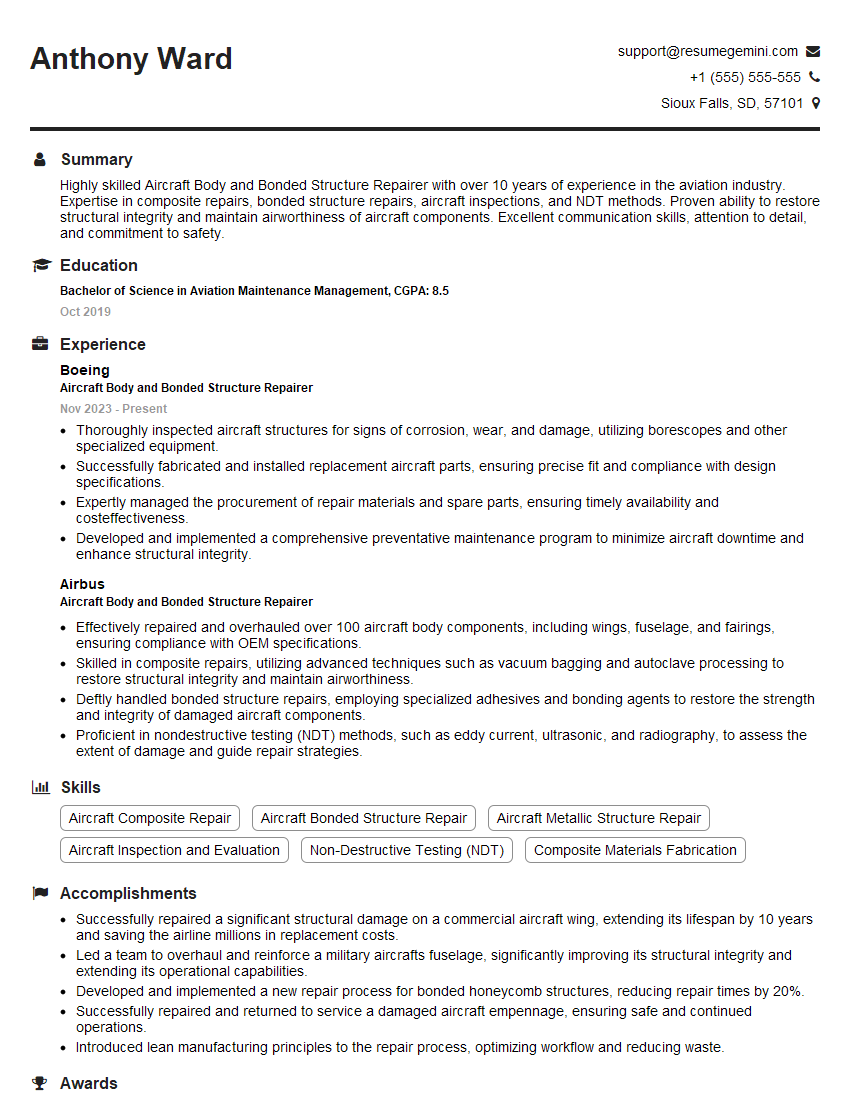

Anthony Ward

Aircraft Body and Bonded Structure Repairer

Summary

Highly skilled Aircraft Body and Bonded Structure Repairer with over 10 years of experience in the aviation industry. Expertise in composite repairs, bonded structure repairs, aircraft inspections, and NDT methods. Proven ability to restore structural integrity and maintain airworthiness of aircraft components. Excellent communication skills, attention to detail, and commitment to safety.

Education

Bachelor of Science in Aviation Maintenance Management

October 2019

Skills

- Aircraft Composite Repair

- Aircraft Bonded Structure Repair

- Aircraft Metallic Structure Repair

- Aircraft Inspection and Evaluation

- Non-Destructive Testing (NDT)

- Composite Materials Fabrication

Work Experience

Aircraft Body and Bonded Structure Repairer

- Thoroughly inspected aircraft structures for signs of corrosion, wear, and damage, utilizing borescopes and other specialized equipment.

- Successfully fabricated and installed replacement aircraft parts, ensuring precise fit and compliance with design specifications.

- Expertly managed the procurement of repair materials and spare parts, ensuring timely availability and costeffectiveness.

- Developed and implemented a comprehensive preventative maintenance program to minimize aircraft downtime and enhance structural integrity.

Aircraft Body and Bonded Structure Repairer

- Effectively repaired and overhauled over 100 aircraft body components, including wings, fuselage, and fairings, ensuring compliance with OEM specifications.

- Skilled in composite repairs, utilizing advanced techniques such as vacuum bagging and autoclave processing to restore structural integrity and maintain airworthiness.

- Deftly handled bonded structure repairs, employing specialized adhesives and bonding agents to restore the strength and integrity of damaged aircraft components.

- Proficient in nondestructive testing (NDT) methods, such as eddy current, ultrasonic, and radiography, to assess the extent of damage and guide repair strategies.

Accomplishments

- Successfully repaired a significant structural damage on a commercial aircraft wing, extending its lifespan by 10 years and saving the airline millions in replacement costs.

- Led a team to overhaul and reinforce a military aircrafts fuselage, significantly improving its structural integrity and extending its operational capabilities.

- Developed and implemented a new repair process for bonded honeycomb structures, reducing repair times by 20%.

- Successfully repaired and returned to service a damaged aircraft empennage, ensuring safe and continued operations.

- Introduced lean manufacturing principles to the repair process, optimizing workflow and reducing waste.

Awards

- Awarded Top Aircraft Bonded Structure Repairer of the Year for exceptional performance in composite and metallic airframe repair and restoration.

- Recognized for innovative techniques in using advanced bonding adhesives to enhance aircraft skin integrity.

- Received certification as an FAAlicensed Aircraft Body and Bonded Structure Repairer, meeting the highest industry standards.

- Honored for exceptional attention to detail and adherence to quality standards in composite aircraft repair.

Certificates

- FAA Aircraft and Powerplant Mechanic License (A&P)

- Society of Automotive Engineers (SAE) ARP1592 Certification

- FAA Composites Repair Training Program

- NDT Level II Certification (e.g., Ultrasonic, Eddy Current, Magnetic Particle)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Body and Bonded Structure Repairer

- Highlight your experience and skills in aircraft body and bonded structure repair in the resume summary.

- Quantify your accomplishments and provide specific examples of your work in the experience section.

- Obtain relevant certifications, such as FAA Airframe and Powerplant (A&P) license, to demonstrate your credibility.

- Network with professionals in the aviation industry to learn about potential job opportunities.

- Continuously update your knowledge and skills by attending industry conferences and training programs.

Essential Experience Highlights for a Strong Aircraft Body and Bonded Structure Repairer Resume

- Repair and overhaul aircraft body components, including wings, fuselage, and fairings, to OEM specifications

- Perform composite repairs using advanced techniques such as vacuum bagging and autoclave processing

- Repair bonded structures using specialized adhesives and bonding agents to restore strength and integrity

- Conduct NDT inspections to assess damage and guide repair strategies

- Inspect aircraft structures for corrosion, wear, and damage using borescopes and other specialized equipment

- Fabricate and install replacement aircraft parts to ensure precise fit and compliance with design specifications

- Manage the procurement of repair materials and spare parts to ensure timely availability and cost-effectiveness

Frequently Asked Questions (FAQ’s) For Aircraft Body and Bonded Structure Repairer

What are the key skills required to be an Aircraft Body and Bonded Structure Repairer?

Aircraft Composite Repair, Aircraft Bonded Structure Repair, Aircraft Metallic Structure Repair, Aircraft Inspection and Evaluation, Non-Destructive Testing (NDT), Composite Materials Fabrication.

What are the educational requirements to become an Aircraft Body and Bonded Structure Repairer?

Typically an associate’s degree or higher in Aviation Maintenance Management, or a related field, is required.

What are the career prospects for an Aircraft Body and Bonded Structure Repairer?

With experience, one can advance to roles such as Lead Repair Technician, Maintenance Supervisor, or Quality Control Inspector.

What are the working conditions like for an Aircraft Body and Bonded Structure Repairer?

Typically, work is performed in a hangar or workshop environment, often involving physical labor and exposure to chemicals and noise.

What are the salary expectations for an Aircraft Body and Bonded Structure Repairer?

Salary can vary depending on experience, location, and employer, but generally ranges from $60,000 to $100,000 per year.

What are the benefits of working as an Aircraft Body and Bonded Structure Repairer?

Job stability, competitive salary, opportunities for career advancement, and the satisfaction of contributing to the safety and reliability of aircraft.

What are the challenges of working as an Aircraft Body and Bonded Structure Repairer?

Physically demanding work, exposure to hazardous materials, and the need to stay up-to-date with industry regulations and technologies.