Are you a seasoned Aligning Inspector seeking a new career path? Discover our professionally built Aligning Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

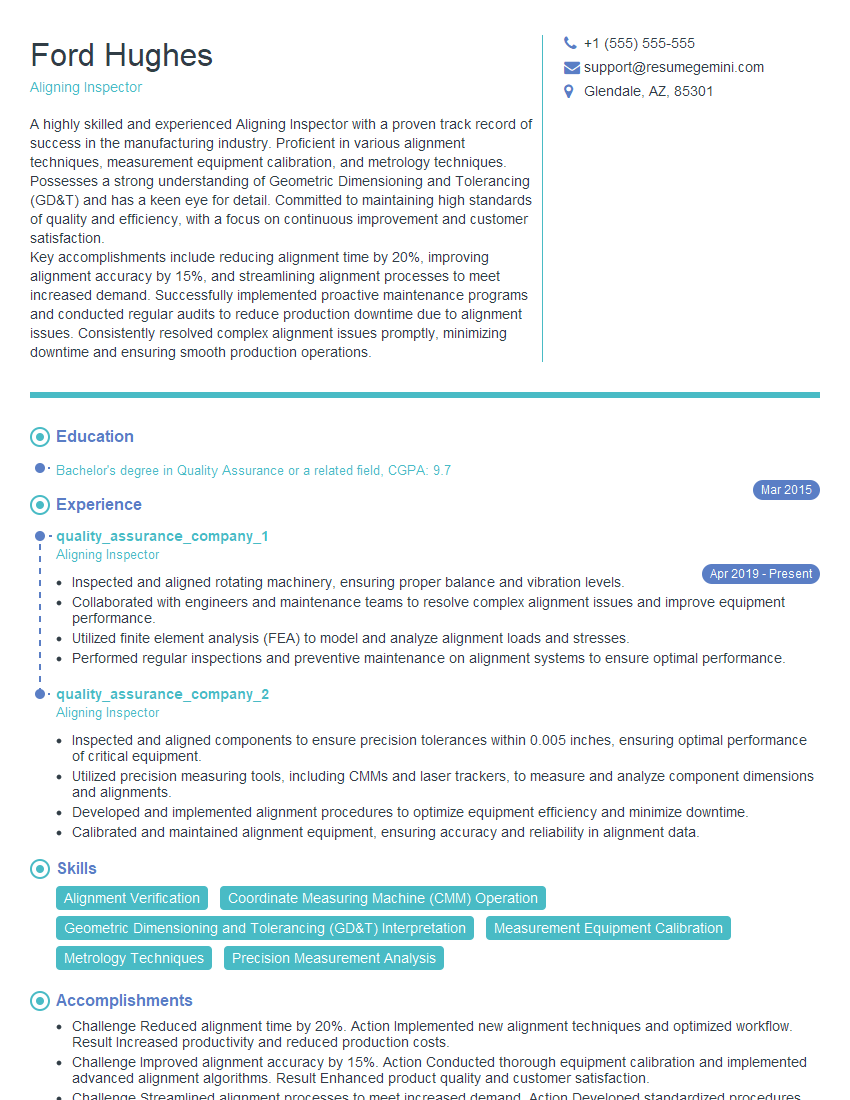

Ford Hughes

Aligning Inspector

Summary

A highly skilled and experienced Aligning Inspector with a proven track record of success in the manufacturing industry. Proficient in various alignment techniques, measurement equipment calibration, and metrology techniques. Possesses a strong understanding of Geometric Dimensioning and Tolerancing (GD&T) and has a keen eye for detail. Committed to maintaining high standards of quality and efficiency, with a focus on continuous improvement and customer satisfaction.

Key accomplishments include reducing alignment time by 20%, improving alignment accuracy by 15%, and streamlining alignment processes to meet increased demand. Successfully implemented proactive maintenance programs and conducted regular audits to reduce production downtime due to alignment issues. Consistently resolved complex alignment issues promptly, minimizing downtime and ensuring smooth production operations.

Education

Bachelor’s degree in Quality Assurance or a related field

March 2015

Skills

- Alignment Verification

- Coordinate Measuring Machine (CMM) Operation

- Geometric Dimensioning and Tolerancing (GD&T) Interpretation

- Measurement Equipment Calibration

- Metrology Techniques

- Precision Measurement Analysis

Work Experience

Aligning Inspector

- Inspected and aligned rotating machinery, ensuring proper balance and vibration levels.

- Collaborated with engineers and maintenance teams to resolve complex alignment issues and improve equipment performance.

- Utilized finite element analysis (FEA) to model and analyze alignment loads and stresses.

- Performed regular inspections and preventive maintenance on alignment systems to ensure optimal performance.

Aligning Inspector

- Inspected and aligned components to ensure precision tolerances within 0.005 inches, ensuring optimal performance of critical equipment.

- Utilized precision measuring tools, including CMMs and laser trackers, to measure and analyze component dimensions and alignments.

- Developed and implemented alignment procedures to optimize equipment efficiency and minimize downtime.

- Calibrated and maintained alignment equipment, ensuring accuracy and reliability in alignment data.

Accomplishments

- Challenge Reduced alignment time by 20%. Action Implemented new alignment techniques and optimized workflow. Result Increased productivity and reduced production costs.

- Challenge Improved alignment accuracy by 15%. Action Conducted thorough equipment calibration and implemented advanced alignment algorithms. Result Enhanced product quality and customer satisfaction.

- Challenge Streamlined alignment processes to meet increased demand. Action Developed standardized procedures and trained junior inspectors. Result Increased capacity and decreased turnaround time.

- Challenge Reduced production downtime due to alignment issues. Action Implemented proactive maintenance programs and conducted regular audits. Result Improved equipment reliability and minimized production disruptions.

- Challenge Resolved complex alignment issues promptly. Action Utilized advanced troubleshooting techniques and collaborated with engineers. Result Minimized downtime and ensured smooth production operations.

Awards

- Received the Accuracy and Precision Award for consistently achieving the highest accuracy and precision in alignment tasks.

- Recognized with the Calibration Excellence Award for maintaining and calibrating alignment equipment to the highest industry standards.

- Awarded the Alignment Star Award for exceptional proficiency and expertise in alignment procedures.

- Honored with the Alignment Inspector of the Year award for outstanding performance in the field.

Certificates

- ASME B5.14 Dimensional Measurement Standard

- ISO 90012015 Quality Management Systems

- Coordinate Measuring Machine Operator Certification

- GD&T Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aligning Inspector

- Highlight your expertise in alignment techniques, measurement equipment calibration, and GD&T interpretation.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your commitment to quality and continuous improvement through examples of your contributions.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience most relevant to the role.

Essential Experience Highlights for a Strong Aligning Inspector Resume

- Conduct alignment inspections on a variety of products using Coordinate Measuring Machines (CMMs) and other precision measuring equipment.

- Verify alignment accuracy based on Geometric Dimensioning and Tolerancing (GD&T) specifications.

- Calibrate and maintain measurement equipment to ensure accuracy and reliability.

- Develop and implement alignment procedures to improve efficiency and accuracy.

- Troubleshoot and resolve complex alignment issues.

- Analyze measurement data and provide feedback to production teams to improve processes.

- Maintain records and generate reports on alignment inspections and findings.

Frequently Asked Questions (FAQ’s) For Aligning Inspector

What are the primary responsibilities of an Aligning Inspector?

Aligning Inspectors are responsible for ensuring that products meet the required alignment specifications. This involves conducting alignment inspections using Coordinate Measuring Machines (CMMs) and other precision measuring equipment, verifying alignment accuracy based on Geometric Dimensioning and Tolerancing (GD&T) specifications, calibrating and maintaining measurement equipment, and developing and implementing alignment procedures to improve efficiency and accuracy.

What are the key skills and qualifications required to be an Aligning Inspector?

To be successful as an Aligning Inspector, you typically need a high school diploma or equivalent, along with specialized training in alignment techniques, measurement equipment calibration, and GD&T interpretation. You should also have strong analytical and problem-solving skills, as well as the ability to work independently and as part of a team.

What are the career prospects for Aligning Inspectors?

With the increasing demand for quality control in manufacturing, the job outlook for Aligning Inspectors is expected to be positive. As technology advances and products become more complex, the need for skilled inspectors will only grow. With experience and additional training, Aligning Inspectors can advance to supervisory or management positions.

What are some of the challenges that Aligning Inspectors face?

Aligning Inspectors may face challenges such as working with complex products or equipment, meeting tight deadlines, and maintaining high standards of accuracy. They may also need to stay up-to-date with the latest alignment techniques and technologies to ensure they are using the most effective methods.

What are the key qualities of a successful Aligning Inspector?

Successful Aligning Inspectors typically have a strong attention to detail, analytical and problem-solving skills, and the ability to work independently and as part of a team. They are also committed to maintaining high standards of quality and are willing to learn new techniques and technologies.

What are some of the industries that employ Aligning Inspectors?

Aligning Inspectors are employed in a variety of industries, including manufacturing, automotive, aerospace, and electronics. They work in quality control departments, ensuring that products meet the required alignment specifications.

What are the salary expectations for Aligning Inspectors?

The salary expectations for Aligning Inspectors can vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for an Aligning Inspector in the United States is around $55,000 per year.

What are some tips for writing a standout Aligning Inspector resume?

To write a standout Aligning Inspector resume, you should highlight your expertise in alignment techniques, measurement equipment calibration, and GD&T interpretation. Quantify your accomplishments with specific metrics and results whenever possible. Demonstrate your commitment to quality and continuous improvement through examples of your contributions. Tailor your resume to each specific job you apply for, highlighting the skills and experience most relevant to the role.