Are you a seasoned Alloy Weigher seeking a new career path? Discover our professionally built Alloy Weigher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

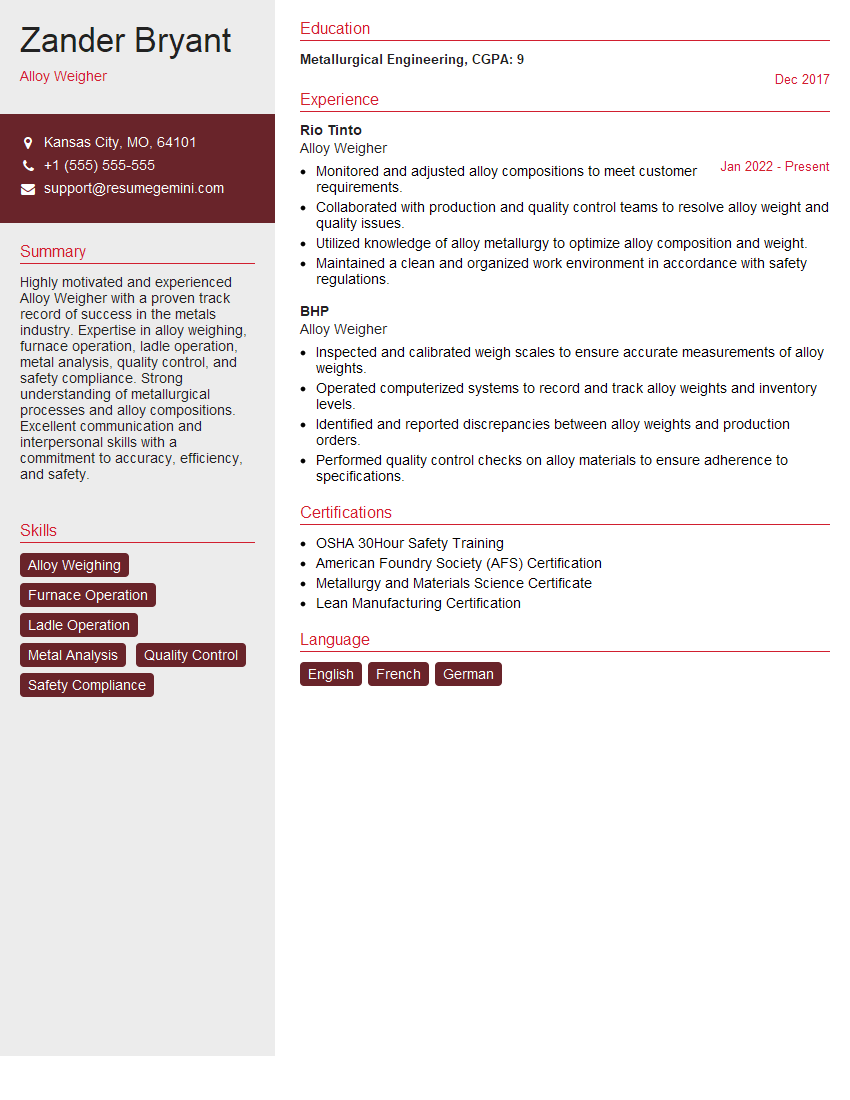

Zander Bryant

Alloy Weigher

Summary

Highly motivated and experienced Alloy Weigher with a proven track record of success in the metals industry. Expertise in alloy weighing, furnace operation, ladle operation, metal analysis, quality control, and safety compliance. Strong understanding of metallurgical processes and alloy compositions. Excellent communication and interpersonal skills with a commitment to accuracy, efficiency, and safety.

Education

Metallurgical Engineering

December 2017

Skills

- Alloy Weighing

- Furnace Operation

- Ladle Operation

- Metal Analysis

- Quality Control

- Safety Compliance

Work Experience

Alloy Weigher

- Monitored and adjusted alloy compositions to meet customer requirements.

- Collaborated with production and quality control teams to resolve alloy weight and quality issues.

- Utilized knowledge of alloy metallurgy to optimize alloy composition and weight.

- Maintained a clean and organized work environment in accordance with safety regulations.

Alloy Weigher

- Inspected and calibrated weigh scales to ensure accurate measurements of alloy weights.

- Operated computerized systems to record and track alloy weights and inventory levels.

- Identified and reported discrepancies between alloy weights and production orders.

- Performed quality control checks on alloy materials to ensure adherence to specifications.

Certificates

- OSHA 30Hour Safety Training

- American Foundry Society (AFS) Certification

- Metallurgy and Materials Science Certificate

- Lean Manufacturing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Alloy Weigher

- Highlight your experience in alloy weighing and other related areas.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Showcase your understanding of metallurgical processes and alloy compositions.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Alloy Weigher Resume

- Weigh and record the weight of alloys used in the production of metal products.

- Operate furnaces to melt and heat alloys to the required temperature.

- Operate ladles to transport molten alloys from the furnace to the casting area.

- Conduct metal analysis to ensure that alloys meet specifications.

- Maintain quality control standards to ensure that metal products meet customer requirements.

- Ensure compliance with all safety regulations and procedures.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Alloy Weigher

What is the role of an Alloy Weigher?

An Alloy Weigher is responsible for weighing and recording the weight of alloys used in the production of metal products. They also operate furnaces to melt and heat alloys to the required temperature, and operate ladles to transport molten alloys from the furnace to the casting area.

What are the qualifications for becoming an Alloy Weigher?

Most Alloy Weighers have a high school diploma or equivalent, and some may have a degree in metallurgy or a related field. They typically have experience in operating furnaces and ladles, and they must be able to understand and follow metallurgical processes.

What are the job duties of an Alloy Weigher?

Alloy Weighers perform a variety of tasks, including weighing and recording the weight of alloys, operating furnaces to melt and heat alloys, operating ladles to transport molten alloys, conducting metal analysis, maintaining quality control standards, and ensuring compliance with safety regulations.

What are the skills required to be an Alloy Weigher?

Alloy Weighers should have strong math and science skills, and they should be able to operate furnaces and ladles safely. They should also be able to understand and follow metallurgical processes, and they should be committed to quality and safety.

What is the work environment of an Alloy Weigher like?

Alloy Weighers typically work in industrial settings, such as foundries and metalworking shops. They may be exposed to heat, noise, and fumes, and they must wear protective clothing and equipment.

What is the career outlook for Alloy Weighers?

The job outlook for Alloy Weighers is expected to be good over the next few years. The demand for metal products is expected to grow, and this will lead to an increased need for Alloy Weighers to produce the alloys used in these products.

What are the earning potential for Alloy Weighers?

The earning potential for Alloy Weighers varies depending on their experience, skills, and location. However, they can typically earn a good wage, and they may be eligible for benefits such as health insurance, paid time off, and a retirement plan.

What are the advancement opportunities for Alloy Weighers?

Alloy Weighers may advance to positions such as Quality Control Inspector, Metallurgical Technician, or Production Supervisor. With additional education and training, they may also become Engineers or Metallurgists.