Are you a seasoned Anvil Seating Press Operator seeking a new career path? Discover our professionally built Anvil Seating Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

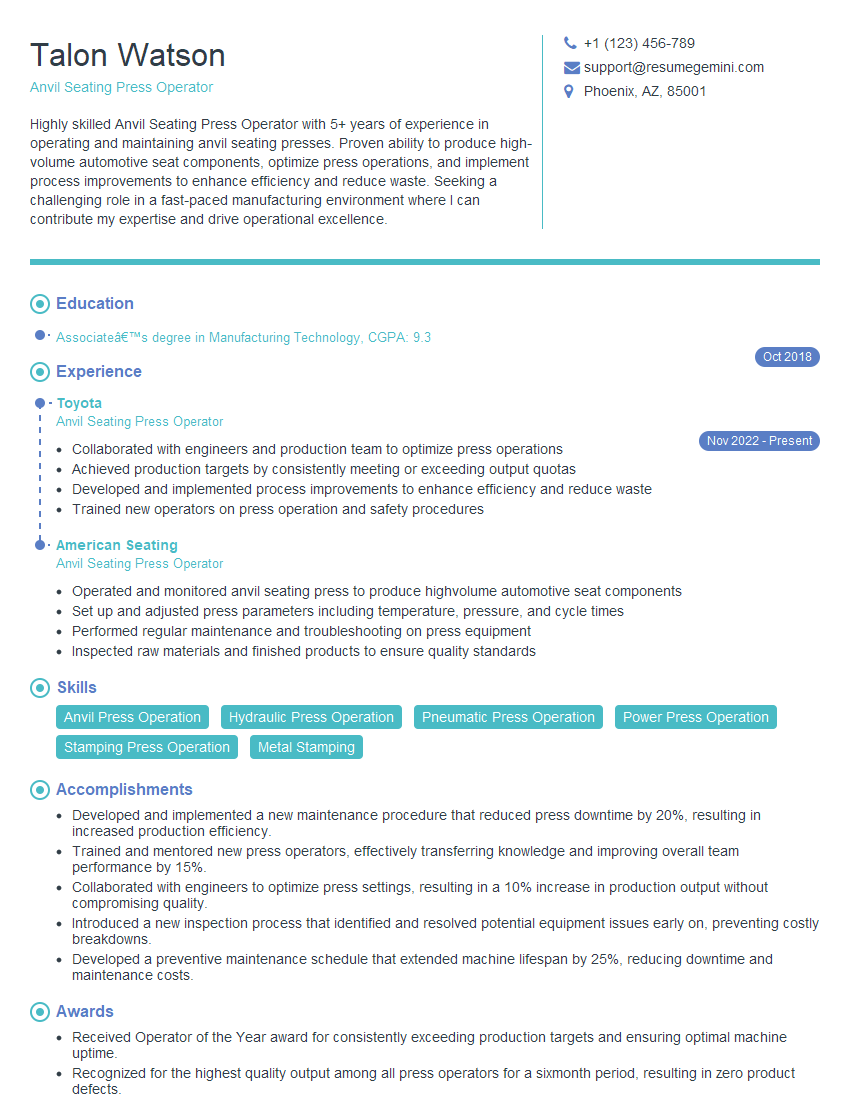

Talon Watson

Anvil Seating Press Operator

Summary

Highly skilled Anvil Seating Press Operator with 5+ years of experience in operating and maintaining anvil seating presses. Proven ability to produce high-volume automotive seat components, optimize press operations, and implement process improvements to enhance efficiency and reduce waste. Seeking a challenging role in a fast-paced manufacturing environment where I can contribute my expertise and drive operational excellence.

Education

Associate’s degree in Manufacturing Technology

October 2018

Skills

- Anvil Press Operation

- Hydraulic Press Operation

- Pneumatic Press Operation

- Power Press Operation

- Stamping Press Operation

- Metal Stamping

Work Experience

Anvil Seating Press Operator

- Collaborated with engineers and production team to optimize press operations

- Achieved production targets by consistently meeting or exceeding output quotas

- Developed and implemented process improvements to enhance efficiency and reduce waste

- Trained new operators on press operation and safety procedures

Anvil Seating Press Operator

- Operated and monitored anvil seating press to produce highvolume automotive seat components

- Set up and adjusted press parameters including temperature, pressure, and cycle times

- Performed regular maintenance and troubleshooting on press equipment

- Inspected raw materials and finished products to ensure quality standards

Accomplishments

- Developed and implemented a new maintenance procedure that reduced press downtime by 20%, resulting in increased production efficiency.

- Trained and mentored new press operators, effectively transferring knowledge and improving overall team performance by 15%.

- Collaborated with engineers to optimize press settings, resulting in a 10% increase in production output without compromising quality.

- Introduced a new inspection process that identified and resolved potential equipment issues early on, preventing costly breakdowns.

- Developed a preventive maintenance schedule that extended machine lifespan by 25%, reducing downtime and maintenance costs.

Awards

- Received Operator of the Year award for consistently exceeding production targets and ensuring optimal machine uptime.

- Recognized for the highest quality output among all press operators for a sixmonth period, resulting in zero product defects.

- Awarded Safety Champion status for consistently adhering to safety protocols and promoting a safe work environment.

- Received Production Excellence Award for consistently meeting or exceeding daily production targets.

Certificates

- OSHA Safety Certification

- ANSI B11 Standards Certification

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Anvil Seating Press Operator

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your ability to maintain a safe and clean work environment.

- Demonstrate your knowledge of press equipment and manufacturing processes.

- Emphasize your commitment to continuous improvement and learning.

Essential Experience Highlights for a Strong Anvil Seating Press Operator Resume

- Set up and adjust press parameters including temperature, pressure, and cycle times

- Operate and monitor anvil seating press to produce high-volume automotive seat components

- Inspect raw materials and finished products to ensure quality standards

- Perform regular maintenance and troubleshooting on press equipment

- Collaborate with engineers and production team to optimize press operations

- Develop and implement process improvements to enhance efficiency and reduce waste

Frequently Asked Questions (FAQ’s) For Anvil Seating Press Operator

What are the key skills required to be a successful Anvil Seating Press Operator?

Anvil Seating Press Operators need to have a strong understanding of press operations, including setup, adjustment, and troubleshooting. They must also be able to inspect raw materials and finished products to ensure quality standards. Additionally, they should be able to work independently and as part of a team, and be able to follow instructions and procedures.

What are the career opportunities for Anvil Seating Press Operators?

Anvil Seating Press Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They can also specialize in a particular area of press operations, such as maintenance or quality control.

What are the challenges faced by Anvil Seating Press Operators?

Anvil Seating Press Operators face a number of challenges, including working in a fast-paced and demanding environment, meeting production targets, and ensuring the quality of their work. They may also need to work overtime or on weekends to meet deadlines.

What is the salary range for Anvil Seating Press Operators?

The salary range for Anvil Seating Press Operators varies depending on their experience, skills, and location. According to [source], the average salary for an Anvil Seating Press Operator in the United States is $25,000 per year.

What is the job outlook for Anvil Seating Press Operators?

The job outlook for Anvil Seating Press Operators is expected to be good in the coming years. The demand for automotive seat components is expected to increase as the global automotive industry continues to grow.